Split bin type reaction furnace applicable to salting-out processes

A technology of reaction furnace and salting-out method, applied in the field of split-silo type reaction furnace, can solve the problems of incomplete material, whisker interference, prolonged precipitation time, etc., and achieve the effect of complete and complete reaction, uniform and stable temperature, and full utilization of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

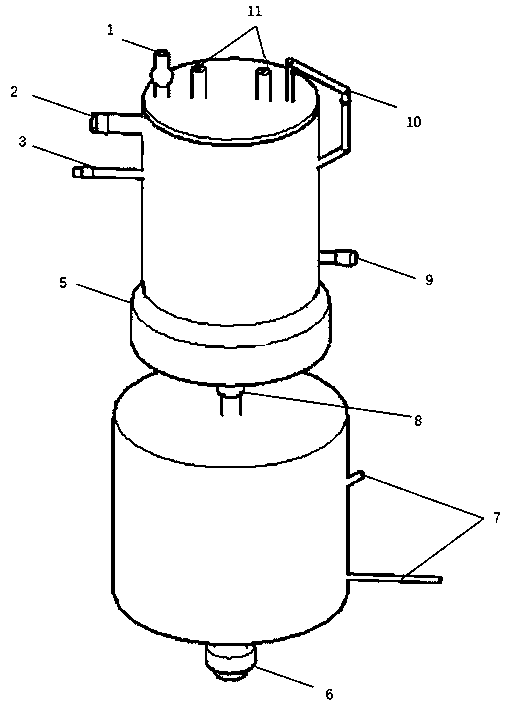

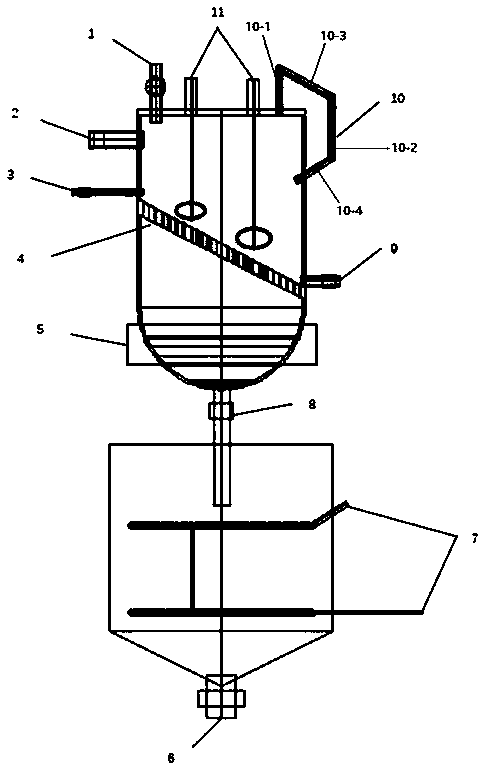

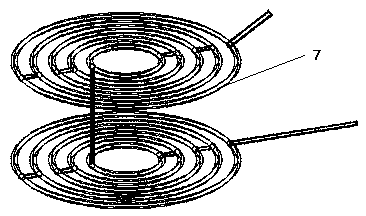

[0016] Embodiment 1: as Figure 1-2 As shown, a compartment-type reaction furnace suitable for the salting-out method includes an upper furnace body and a lower furnace body, both of which are made of anti-corrosion and anti-rust materials, and a gate valve 8 is provided at the connection between the two. One side of the upper furnace body is provided with a feed port 2 and a cleaning port 3, and the other side is provided with a discharge port 9, and the top of the upper furnace body is provided with a safety valve 1 and a safety valve for controlling the air pressure and exhaust in the furnace. In the condensing device 10 for cooling water vapor and ammonia, an inclined filter screen 4 is provided inside the upper furnace body. Equipment 5. The heating equipment 5 is composed of electric heating elements. The electric heating elements surround the periphery of the upper furnace body and can be specifically arranged at the lower part of the upper furnace body. It can be conv...

Embodiment 2

[0018] Embodiment 2: the remainder of this embodiment is the same as the previous embodiment, wherein as figure 2 As shown, in this embodiment, the inclination angle of the filter screen 4 is set to 30°, and the mesh number of the filter screen 4 is set to 300 mesh. The stirring device 11 includes multiple groups of stirring structures, each group is composed of motors, stirring shafts and stirring blades connected in sequence, the motors extend out of the top of the upper furnace body, and the lengths of the stirring shafts in each group of stirring structures are different, corresponding to filter above the net 4. In this embodiment, two sets of stirring structures are set, wherein the stirring shafts are long and short, the long stirring shaft is located above the lower side of the filter screen 4, and the short stirring shaft is located above the higher side of the filter screen 4. Set up a few more sets of stirring structures, which can make the material react more full...

Embodiment 3

[0020] Embodiment 3: the remainder of this embodiment is the same as the previous embodiment, wherein as figure 1 As shown, the condensing device 10 is composed of condensing pipes, including vertical pipe I10-1, vertical pipe II10-2, horizontal pipe I10-3, and horizontal pipe II10-4, wherein the bottom of vertical pipe I10-1 is fixed on the upper furnace The upper end of the vertical pipe I10-1 is connected to the vertical pipe II10-2 through the horizontal pipe I10-3, and the vertical pipe II10-2 is connected to the horizontal pipe II10-4, and the horizontal pipe II10-4 is connected to the upper furnace The side wall of the body, and the horizontal pipe I10-3 and the horizontal pipe II10-4 are inclined downward along the flow direction of the medium. In this embodiment, the inclination angle of the two is set to 40°. When the material reacts in the upper furnace body When the temperature is too high, water vapor and ammonia gas will be generated, and the temperature is too h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com