A method for preparing sucralose by continuous deacetylation of sucralose-6-acetate

A technology for preparing sucralose and sucralose by acetyl group, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems such as no continuous production, and achieves easy control of reaction temperature and saving. Production cost, effect of low sucralose content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

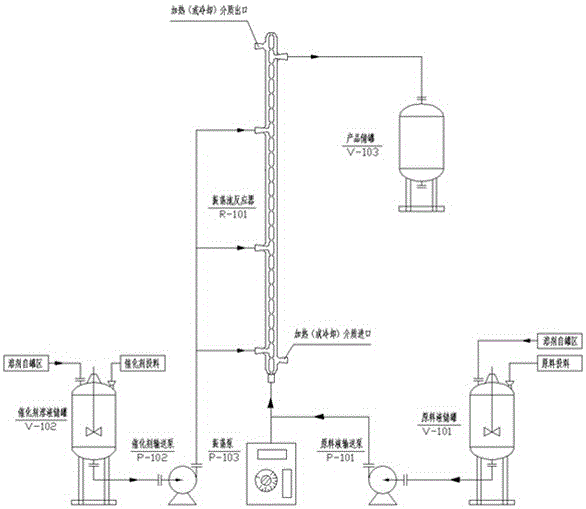

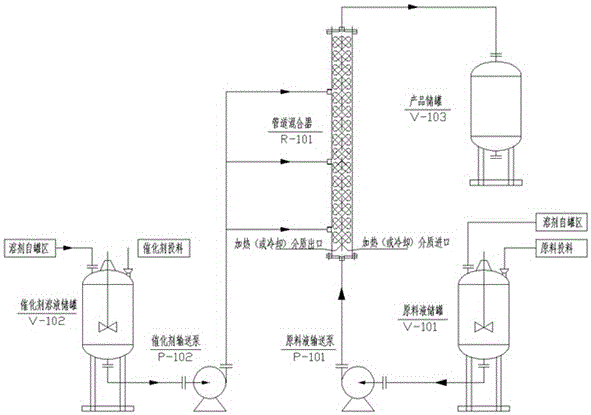

[0024] The sucralose-6-acetate and the solvent methanol are prepared in a molar ratio of 1:40 to make a raw material solution, and the catalyst sodium methoxide and the solvent methanol are prepared in a molar ratio of 1:120 to make a catalyst solution. A reactor using oscillatory flow as a continuous production process.

[0025] Turn on the super constant temperature water tank and stabilize the temperature of the circulating water to 40°C. Turn on the raw material liquid delivery pump to continuously transport the raw material liquid to the oscillating flow reactor, and at the same time turn on the electromagnetic metering pump (ie the oscillating pump), adjust the oscillation frequency to 1Hz, and the oscillation amplitude to 0.02m. The reaction residence time was 30 min. When the height of the raw material liquid in the reactor reaches the height of the catalyst inlet, the catalyst delivery pump is turned on to transport the catalyst solution to the oscillating flow react...

Embodiment 2

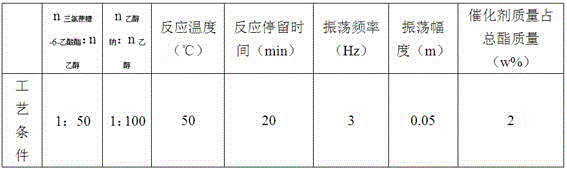

[0028] According to the method of Example 1, the deacetylation reaction of sucralose-6-acetate is carried out, and the process conditions are as follows:

[0029]

[0030] In this reaction, the content of sucralose in the crude sucralose product was 97.15%, the conversion rate of sucralose-6-acetate was 93.5%, and the yield of sucralose was 85.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com