Device for collecting anode slime from bottom of electrolytic cell in zinc electrolytic refining process

An electrolytic cell and anode slime technology, which is applied in the field of zinc electrolysis, can solve the problems of affecting zinc electrolysis production capacity, high manual work intensity, and low work efficiency, and achieve long-term operation, reduce labor intensity of workers, and improve production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

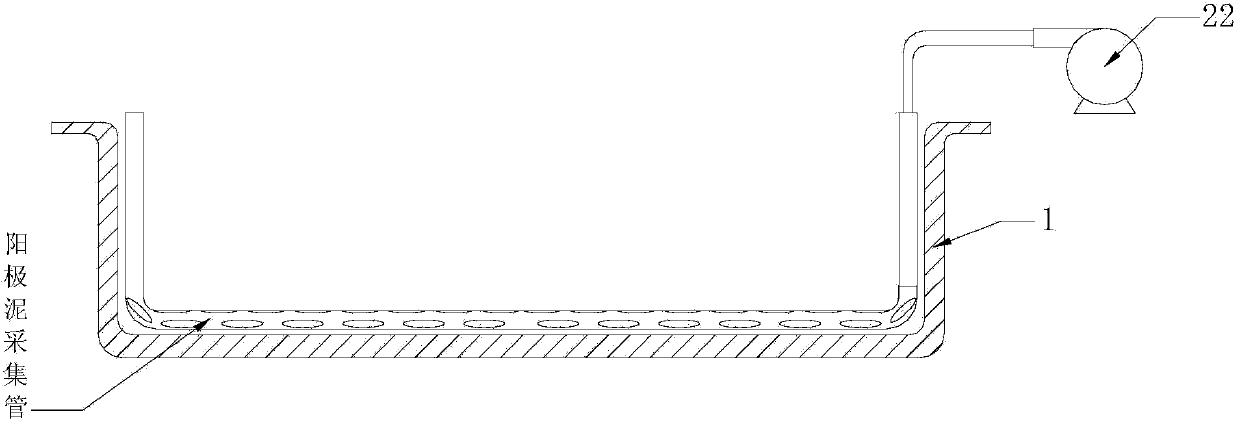

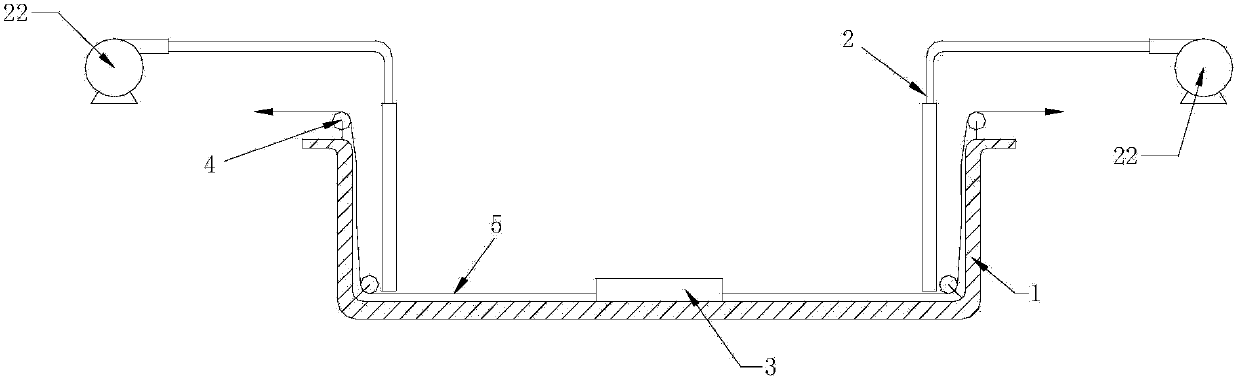

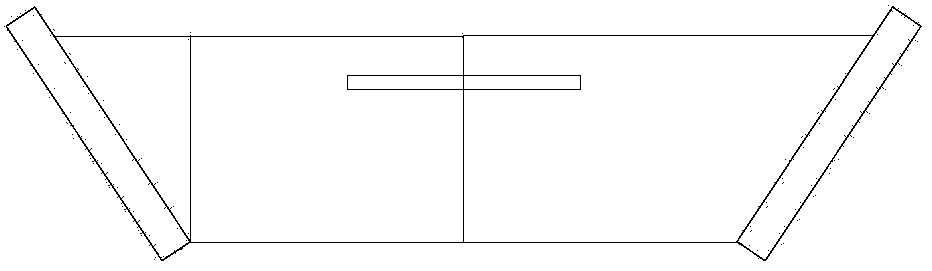

[0016] The present invention will be described in detail below in conjunction with accompanying drawing: figure 2 As shown, the present invention mainly includes an electrolytic cell body 1 and a vacuum suction device 2. The bottom of the electrolytic cell body 1 is trapezoidal in shape, and its purpose is to enable concentrated deposition of anode slime so as to facilitate centralized suction and improve the purpose of pumping rate. An anode slime catcher 3 is arranged at the bottom of the electrolytic cell body 1, and a transmission mechanism 4 is installed at both ends of the electrolytic cell body 1, and the anode slime catcher 3 is connected with the transmission mechanism 4 through a corrosion-resistant traction rope 5; as attached Image 6 As shown, the vacuum suction device 2 is located on both sides of the electrolytic cell body 1, the vacuum suction pipe 21 in the vacuum suction device 2 is inserted into the bottom end of the electrolytic cell body 1, and the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com