Vacuum suction machine with stable performance

A vacuum suction machine and vacuum technology, applied in the field of feeder, can solve the problems of increasing labor intensity, unable to complete powder conveying, low material cleanliness, etc., and achieve the effects of avoiding blockage, enhancing stability, and single air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

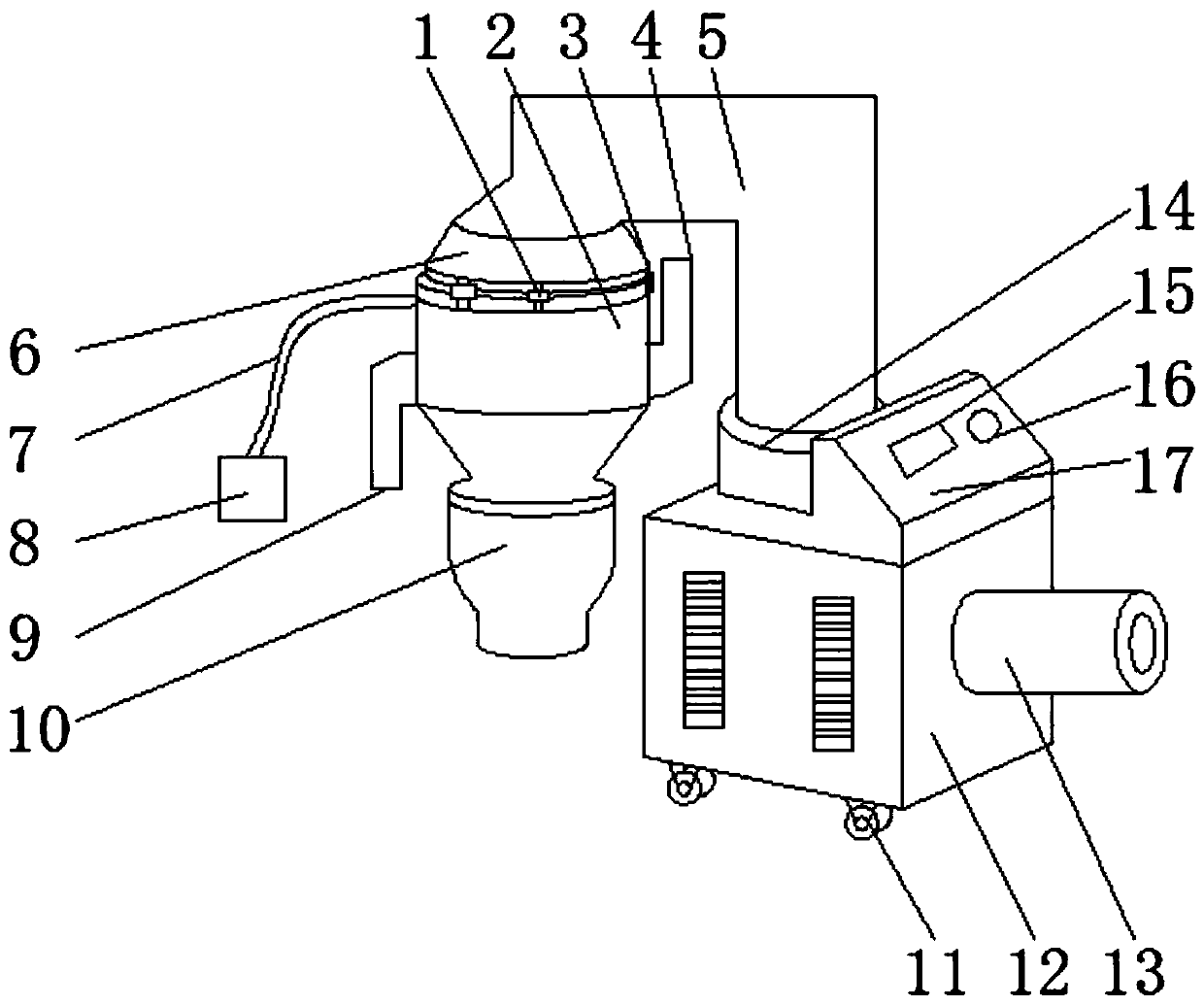

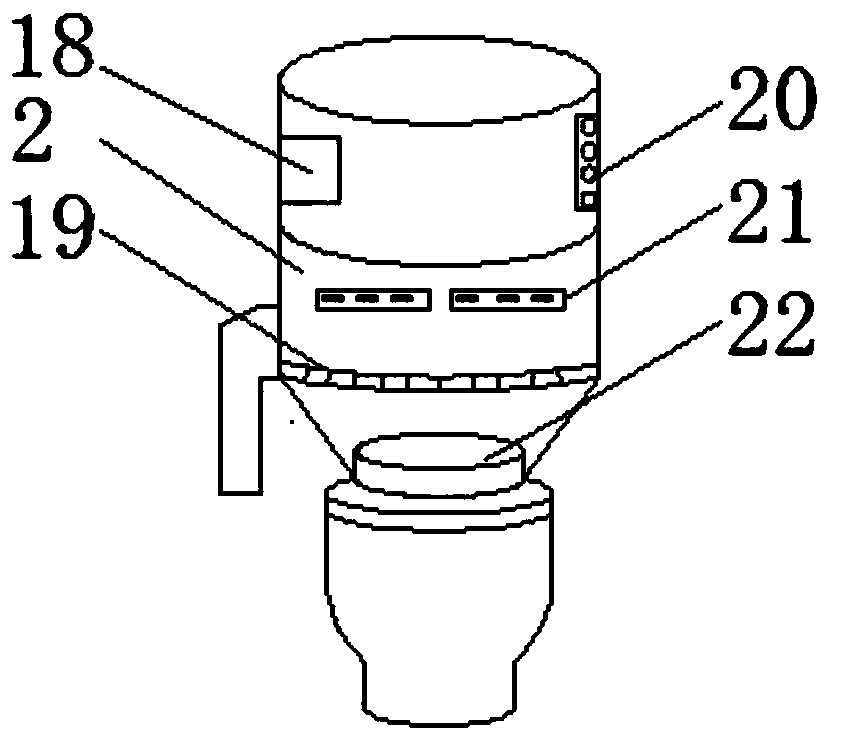

[0015] refer to Figure 1-2 , a vacuum suction machine with stable performance, including a vacuum hopper 2, a sealing cover 6, a vacuum chamber 12 and a control panel 17, a discharge hopper 10 is installed on the lower side of the vacuum hopper 2, and the vacuum hopper 2 connects with the compressed air chamber 8 through the air pipe 7 Connected, the left side surface of the vacuum hopper 2 is equipped with a return air pipe 9, the right side surface of the vacuum hopper 2 is equipped with an air discharge pipe 4, a sealing ring 19 is installed inside the vacuum hopper 2, and a vacuum generator 18 is installed on the upper side of the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com