A built-in range hood oil tank installation structure assembly

A technology of installation structure and engine oil tank, which is applied in the direction of oil fume removal, heating method, household stove/stove, etc. It can solve the problems of low air suction rate and oil fume absorption rate, hindering the smooth entry of oil fume into the filter screen, etc., so as to improve the air suction Efficiency and oil fume absorption rate, enhanced smoothness, and the effect of eliminating the convex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

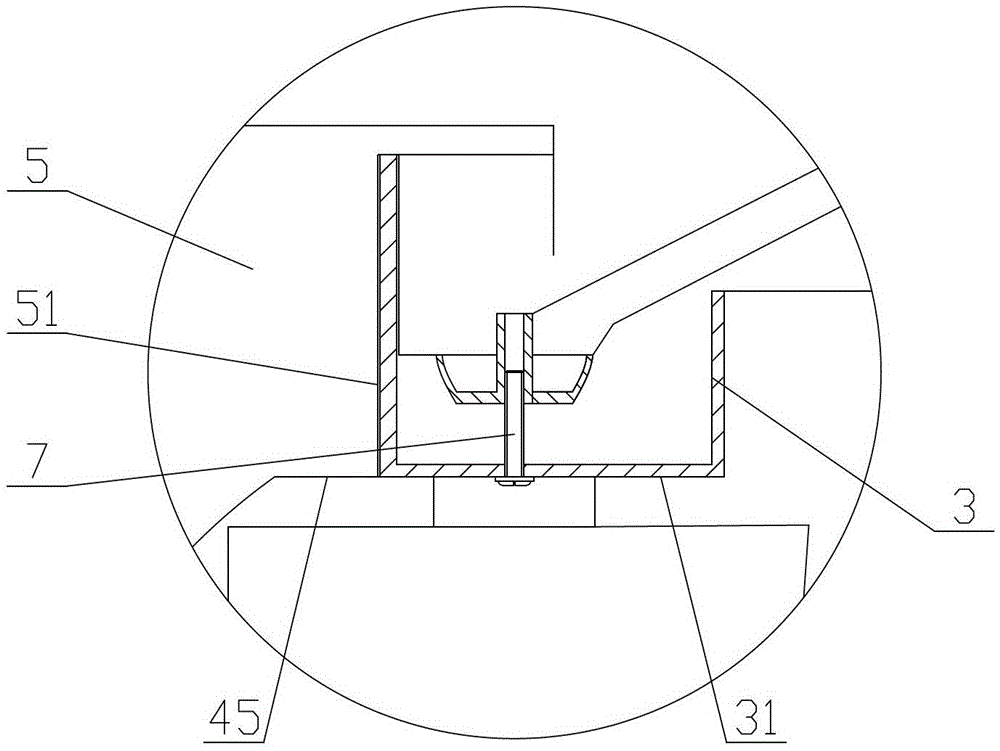

[0030] Example 1, the hood includes a left hood, a right hood, a front hood 4 and a rear hood 5, the oil groove 3 near the side where the front hood 4 is located is a rectangular groove, and the oil groove 3 The bottom surface 31 is at the same level as the outer surface 45 of the fume hood.

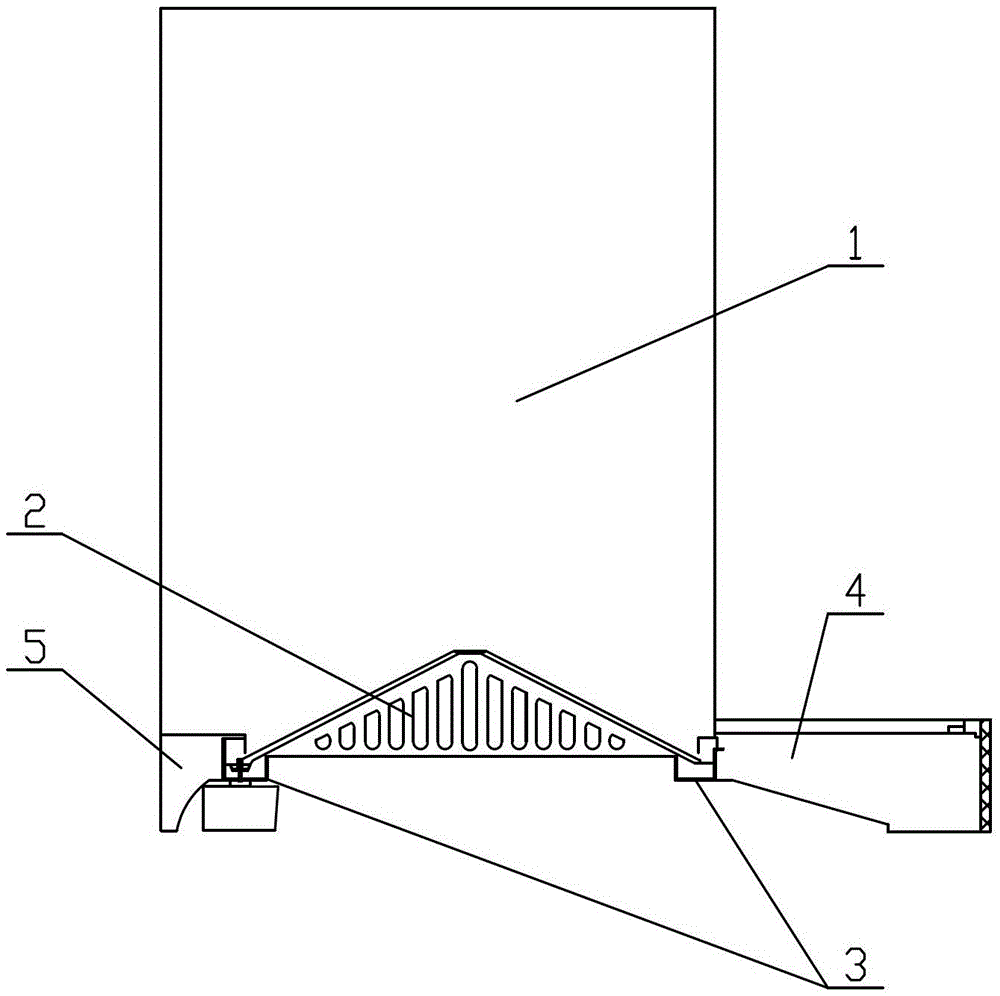

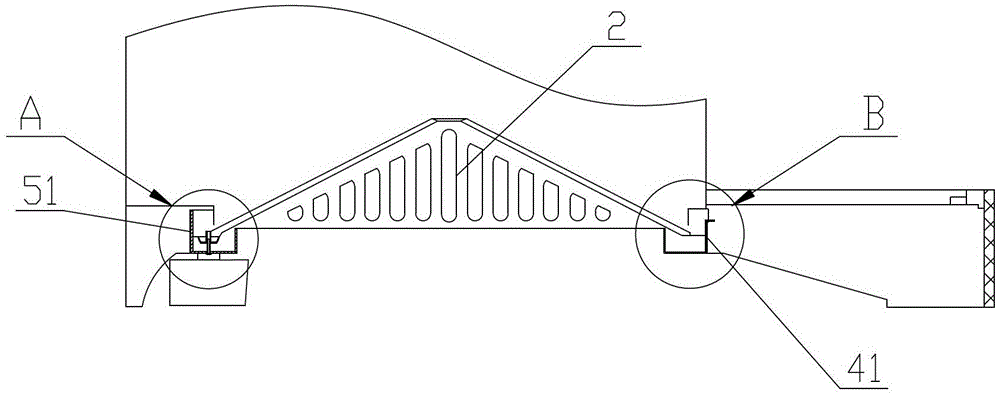

[0031] Such as figure 1 , 2 , 3 and 4 are schematic diagrams of the range hood, the built-in range hood oil tank installation structure assembly, part A and part B respectively.

[0032] Such as figure 1 As shown, a built-in range hood oil tank installation structure assembly includes a housing 1, a filter screen 2 and a fume cover, the filter screen 2 is arranged at the lower part of the housing 1, and the fume cover is arranged at the filter screen 2, an oil tank 3 is arranged below the bottom edge of the filter screen 2, the left smoke hood is arranged under the left side of the housing, and the right smoke hood is arranged on the right side of the housing Below, the front smoke c...

Embodiment 2

[0043] In Embodiment 2, the oil tank 3 near the side where the front hood 4 is located is a trapezoidal groove, and the bottom surface 31 of the oil tank 3 is at the same level as the outer surface 45 of the hood.

[0044] Such as Figure 5 As shown, the oil tank 3 is placed inside a part of the smoke collection chamber, and a part of the smoke collection chamber is composed of the right side wall on the left fume hood, the left side wall on the right fume hood, The rear side wall 41 on the front hood 4 , the front side wall 51 on the rear hood 5 and the lower surface of the filter screen 2 constitute.

[0045] The difference from Example 1 is that the oil tank 3 near the side where the front hood 4 is located is a trapezoidal tank, and the hypotenuse is on the right side of the oil tank 3, thereby effectively avoiding that when the oil tank 3 is a rectangular tank, the right angle of the rectangular tank is right-angled. The defect that has a certain influence on the oil fum...

Embodiment 3

[0046] Embodiment 3, the oil groove 3 near the side where the front hood 4 is located is a triangular groove.

[0047] Such as Image 6 As shown, the oil tank 3 is placed inside a part of the smoke collection chamber, and a part of the smoke collection chamber is composed of the right side wall on the left fume hood, the left side wall on the right fume hood, The rear side wall 41 on the front hood 4 , the front side wall 51 on the rear hood 5 and the lower surface of the filter screen 2 constitute.

[0048] Different from Embodiment 1, the oil groove 3 near the side where the front hood 4 is located is a triangular groove, and this oil groove 3 itself hardly has any influence on the oil fume flow rate entering the filter screen 2, but The capacity of the tank itself is relatively small, which is suitable for larger range hoods. Since the range hood has a larger volume at this time, the capacity of the oil tank 3 is also larger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com