Method for preparing high-purity sodium formate with tail gas of yellow phosphorus stove

A sodium formate and yellow phosphorus furnace technology, applied in carboxylate preparation, organic chemistry, etc., can solve the problems of poor effect, unsatisfactory product quality, small scale, etc., and achieve the effect of overcoming the poor purification of tail gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

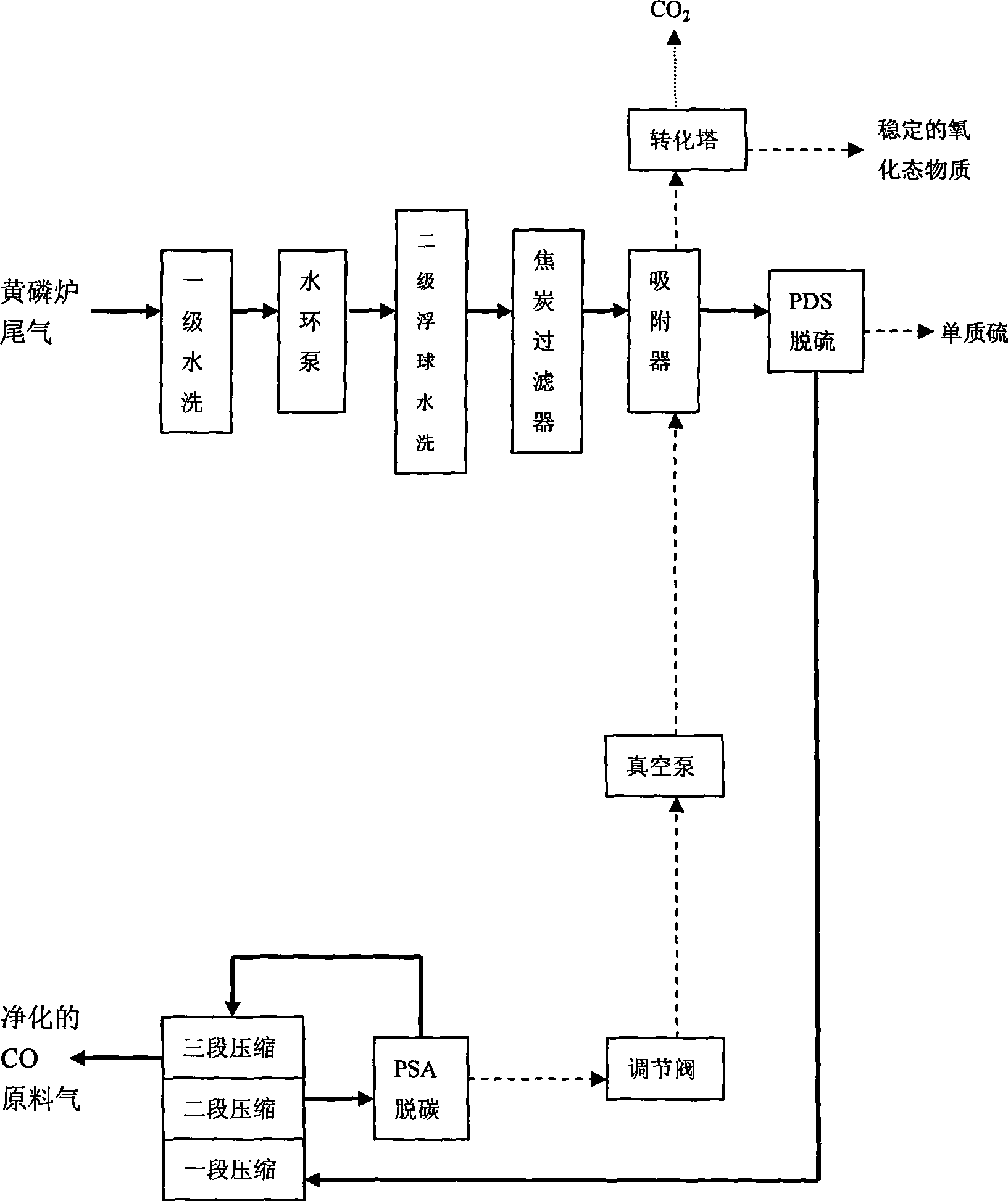

[0017] Guizhou Qingli Group Co., Ltd. has built a 35kt / a device for producing high-purity sodium formate by using the tail gas of the yellow phosphorus furnace, and adopts the purification process of the tail gas of the yellow phosphorus furnace as shown in the attached figure.

[0018] Phosphorus furnace tail gas is first washed by primary water, pumped out by water ring pump, sent to secondary water washing and floating ball type water washing tower after turbulent water washing, sent to coke filter to filter phosphorus mud and other solid impurities, and then enters adsorber to absorb phosphorus, fluorine and arsenic Hydride; then enter the desulfurization tower, adopt wet PDS method to desulfurize, and recover elemental sulfur; in the desulfurized gas, the mass content of hydrogen sulfide is less than 0.001%; the desulfurized gas enters the first and second stages of the compressor, and the pressure is increased to 0.8 After MPa, it enters the decarburizer and uses PSA pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com