Cryogenic separation process for preparing propylene through propane dehydrogenation in Olflex process

A technology for process propane and cryogenic separation, which is applied in cold treatment separation, hydrocarbon purification/separation, refrigerator, etc., can solve the problems of difficult operation of cold box, large influence of process operation, and many process equipment, etc., to achieve long-term cycle Operation, to achieve energy-saving effect, the effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

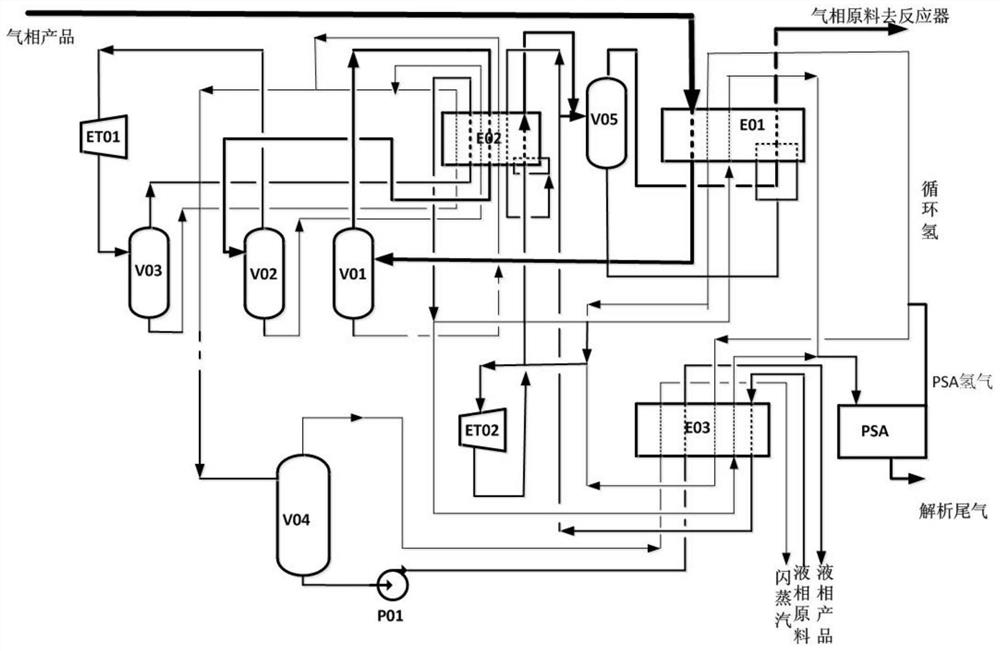

[0029] see figure 1 , the cryogenic separation process for Olflex process propane dehydrogenation to propylene described in the present invention,

[0030] The pressure is 1100 ~ 1500kPa, the temperature is 35-53°C, the reaction gas containing hydrogen and light hydrocarbons such as methane, ethylene, ethane, propylene, propane enters the first group of heat exchanger E01 to cool and condense to -30°C ~ -60°C , and then enter the first liquid separation tank V01 for gas-liquid separation; the gas phase flowing out from the top of the first liquid separation tank enters the second group of heat exchangers E02 to cool to -110 ° C ~ -130 ° C, and then enters the second liquid separation Tank V02 performs gas-liquid separation, and the gas phase flowing out from the top of the second stage liquid tank enters the first high-pressure expander ET01 for expansion and refrigeration. After expansion, the pressure is 600-700kPa and the temperature is -125--150°C. At the same time, the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com