A digital characterization method of coal-fired boiler operating state

A technology of operating status and coal-fired boilers, which is applied in the direction of indicating the working status of boilers, etc., to achieve the effect of real-time practical function improvement and avoiding low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

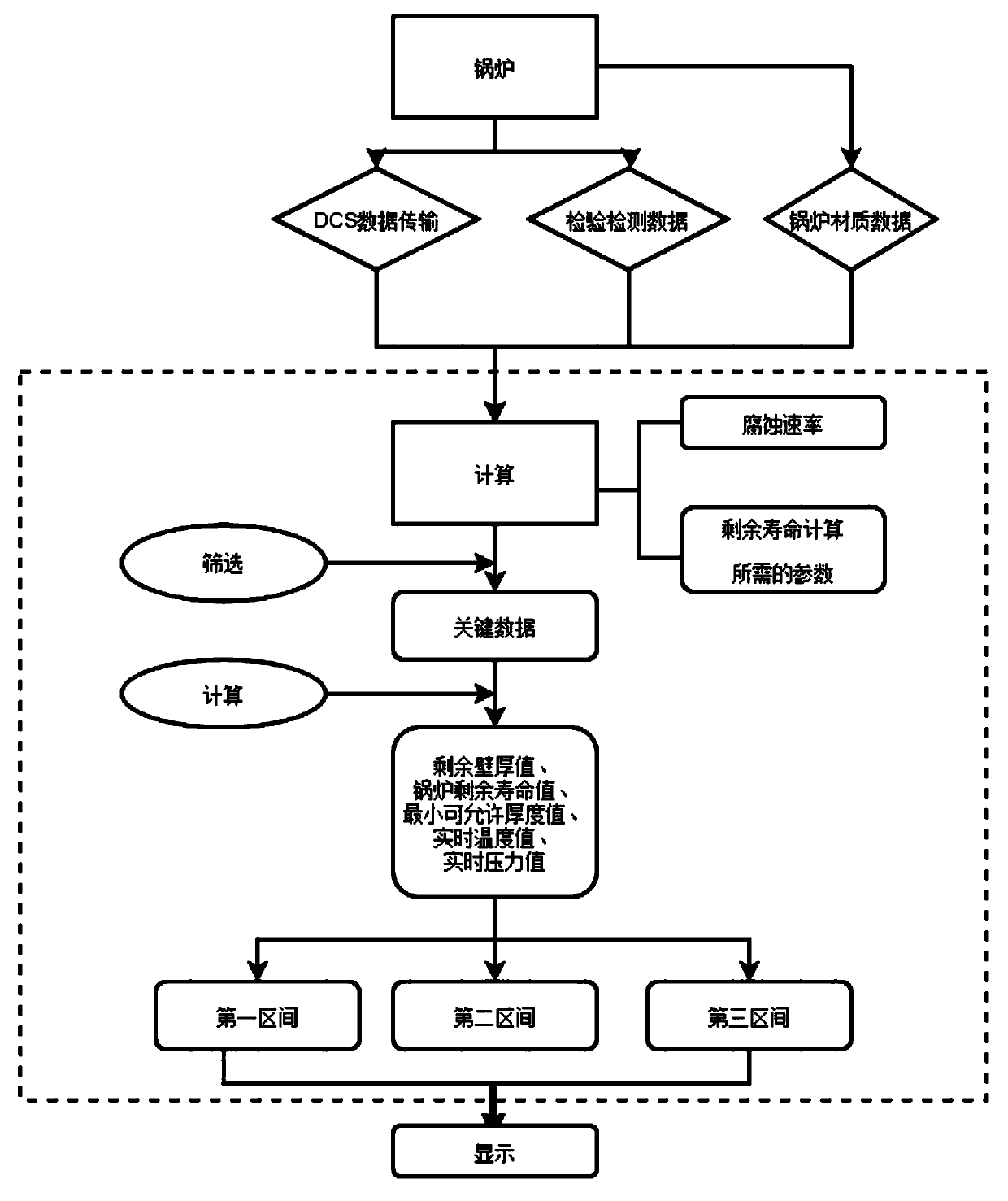

[0040] A digital characterization method of a coal-fired boiler operating state according to the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

[0041] A digital characterization method of the operating state of a coal-fired boiler invented, through centralized calculation and analysis of the data collected from the four tubes of the boiler, the key data (including temperature, pressure, daily inspection and maintenance) that affect the safe operation of the coal-fired power plant boiler , furnace tube life value, etc.) for real-time collection and summary, use these key data to obtain the boiler state parameter value through the corresponding algorithm strategy, according to the boiler state parameter value, give the instant safety level of the boiler safety state, and display it through the display interface The health status and problematic parts of the boiler operation, so as to directly reflect the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com