Non-welded plate type heat exchanger

A plate heat exchanger, non-welded technology, applied in indirect heat exchangers, heat exchanger types, fixed plate conduit assemblies, etc., can solve the problems of complex manufacturing process, poor heat transfer efficiency, complex structure, etc., and achieve a simple structure. Compact, improved service life, good heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

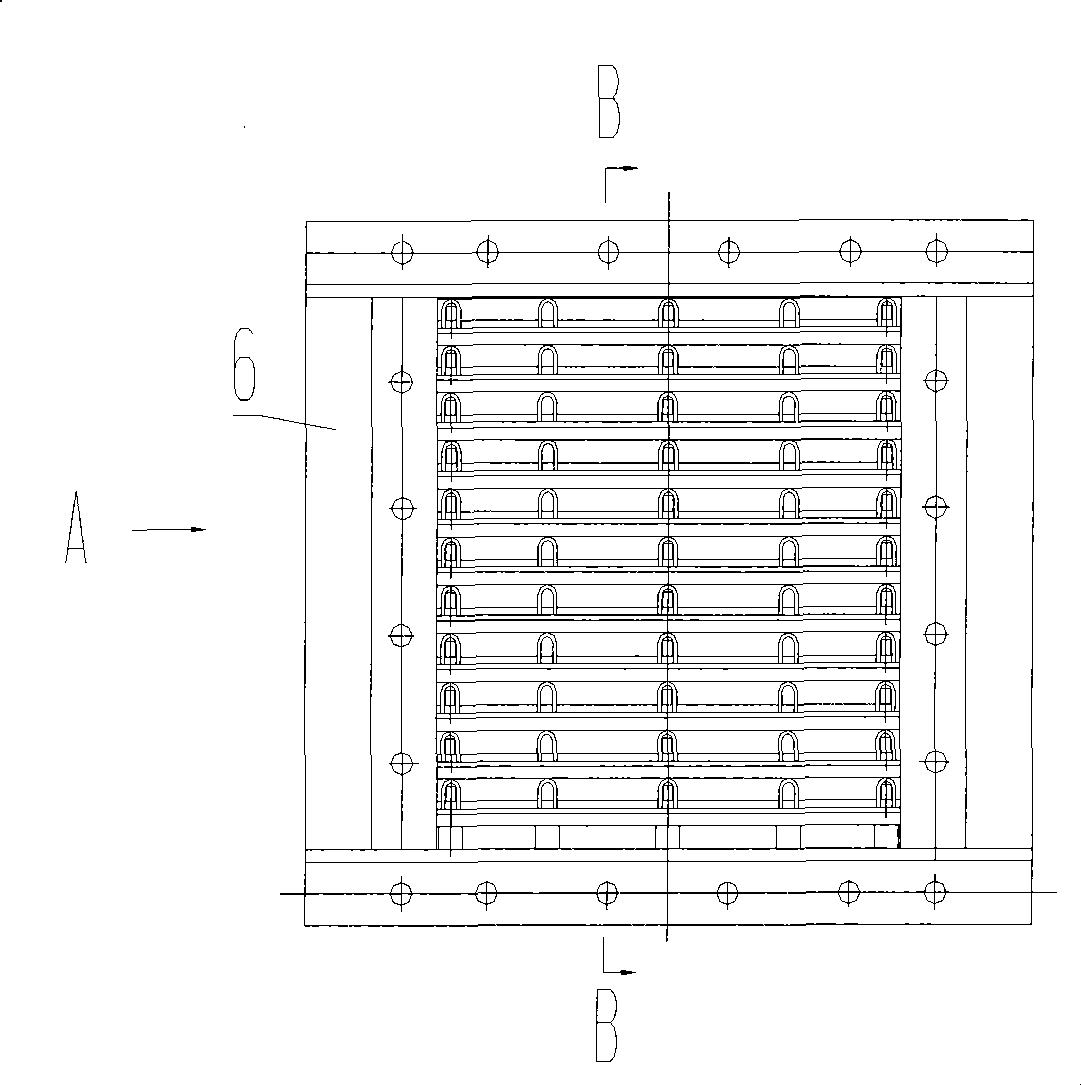

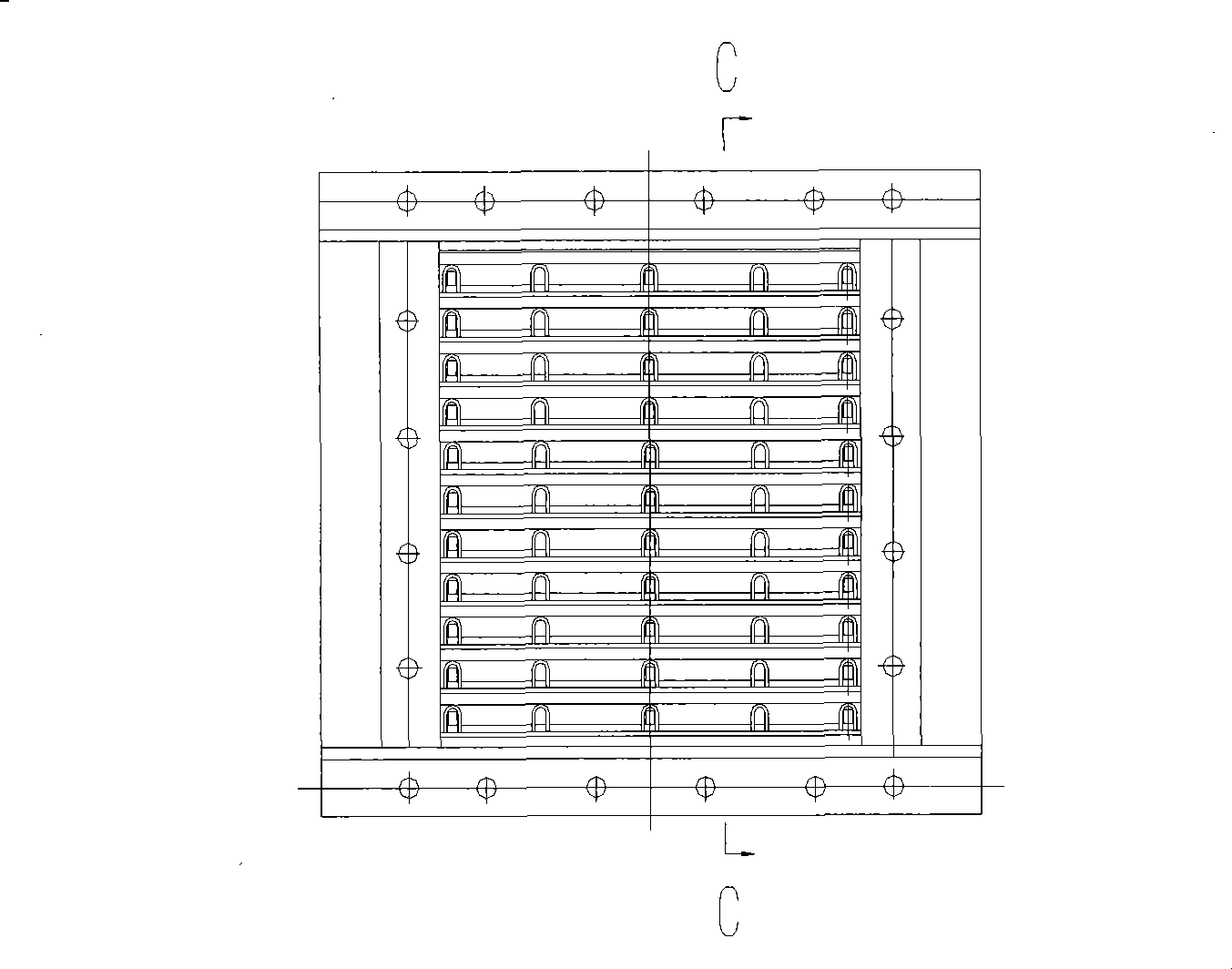

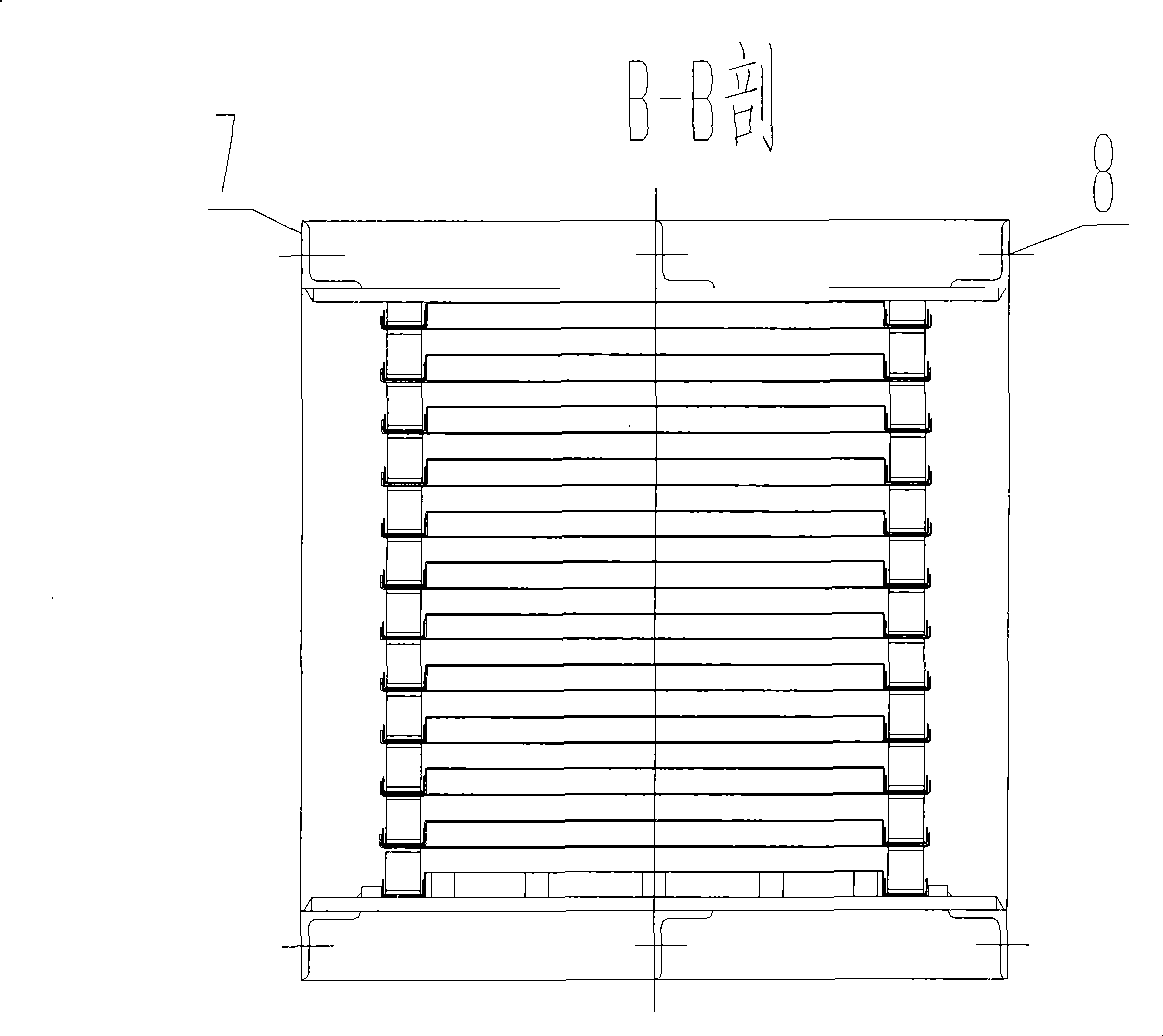

[0028] Embodiment 1: A non-welded plate heat exchanger, consisting of a plurality of heat exchange plates 1 placed up and down staggered to form a plurality of fluid channels, the openings of the adjacent fluid channels in the plurality of fluid channels are staggered by 90°, respectively A hot fluid channel and a cold fluid channel are formed; the hot fluid channel has a hot fluid inlet flange 7 and a hot fluid outlet flange 8, and the cold fluid channel has a cold fluid inlet flange 9 and a cold fluid outlet flange 10; the heat exchange plate Sheet 1 is made of rectangular stainless steel sheet. The above-mentioned components are located in the frame welded by the upper cover plate 11 , the lower cover plate 12 and the column 6 . A sealing gasket 5 is placed between the folded fins of the adjacent upper and lower heat exchange plates 1, and the sealing gasket 5 is a flexible graphite plate; an elastic bead 3 is arranged between two adjacent heat exchange plates , the elasti...

Embodiment 2

[0033] The heat exchange plates 1 are made of rectangular aluminum plates.

[0034] The sealing gasket 5 placed between the hemming fins of the adjacent upper and lower heat exchange plates 1 is a ceramic fiber sealing gasket.

[0035] All the other technical solutions are the same as in Example 1.

Embodiment 3

[0037] The heat exchange plate 1 adopts the structure of coating a layer of enamel on the surface of the metal plate, so as to achieve the purpose of anticorrosion.

[0038] The heat exchange plate 1 can also be a metal plate with corrugations processed on the plate surface, so as to achieve the purpose of improving heat transfer efficiency.

[0039] Several turbulent elements are arranged between the heat exchange plates, so as to achieve the purpose of improving heat transfer efficiency. The turbulence element is a cross zigzag belt and twisted iron.

[0040] All the other technical solutions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com