Chloroform rectification device and rectification process

A chloroform and rectification technology, applied in fractionation, distillation separation, chemical industry and other directions, can solve the problem of frequent blockage of the reboiler of the rectification tower, reduce the demand for heat source quality, save the production cost of enterprises, and avoid the effect of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

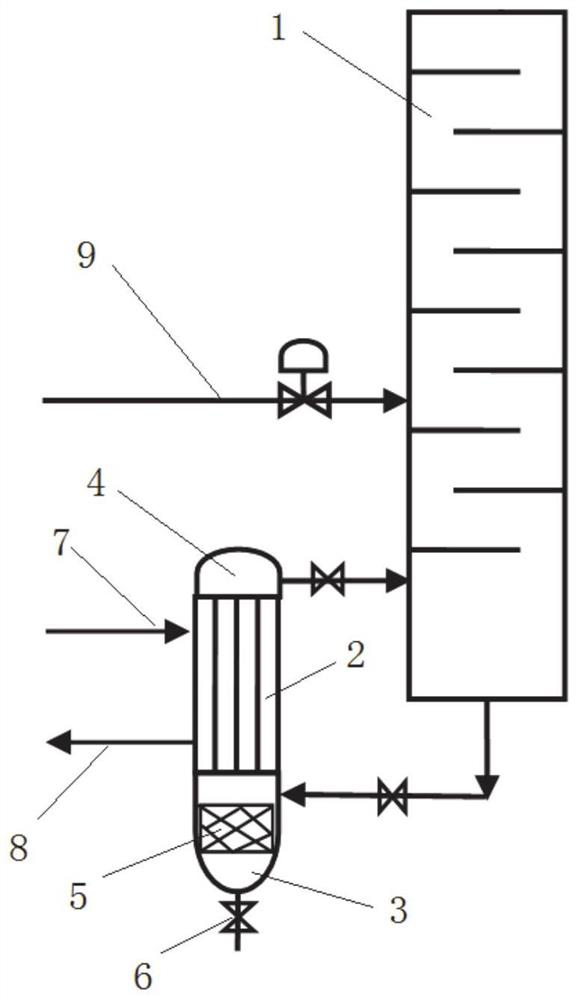

[0050] A chloroform distillation unit, such as figure 1 As shown, a chloroform rectification tower 1 is included, and two parallel reboilers 2 are arranged at the bottom of the chloroform rectification tower 1 .

[0051] The reboiler 2 is a tube-and-tube heat exchanger, and the reboiler 2 is arranged vertically. The length of the lower head 3 of the reboiler 2 in the axial direction of the reboiler 2 is greater than the length of a common head (such as the upper head 4 of the reboiler 2 ), so that a settling zone 5 is formed in the lower head 3 . The bottom head 3 is provided with the tower kettle material inlet and the sewage outlet, and the sewage outlet is provided with a sewage valve 6 . The material inlet of the tower kettle is set above the settling area 5, and the sewage outlet is set below the settling area 5 (that is, the bottom of the lower head 3). The upper head 4 is provided with a tower kettle material outlet.

[0052] The upper heat source inlet 7 of the shel...

Embodiment 2

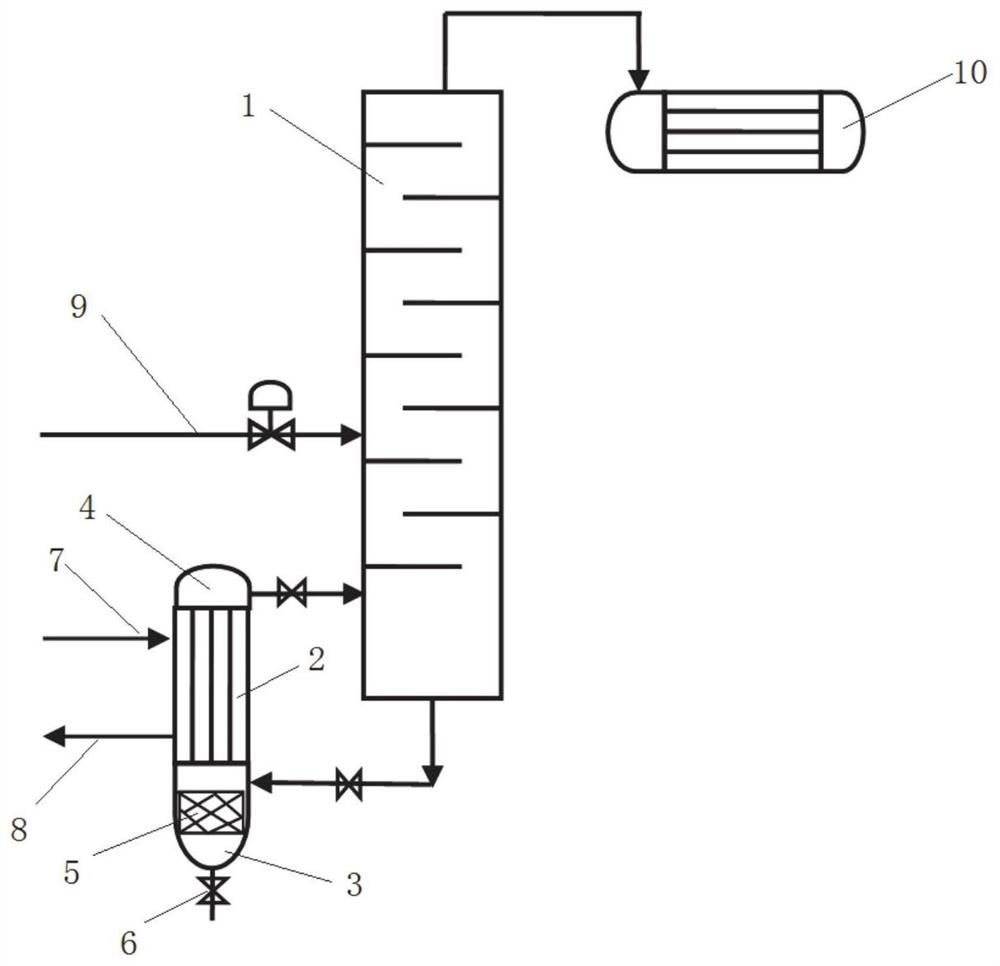

[0059] This embodiment is the same as Embodiment 1, the difference is that, as figure 2 As shown, a top condenser 10 is arranged at the top of the chloroform rectification column 1 .

Embodiment 3

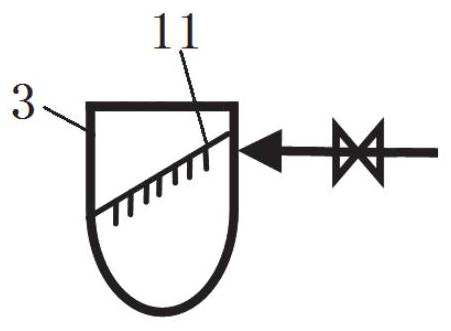

[0061] This embodiment is the same as Embodiment 2, the difference is that, as image 3 As shown, the baffle plate 11 that can be detachably installed in the settling area, the baffle plate 11 is inclined, and one side of the baffle plate 11 is arranged on the top of the material inlet of the reboiler 2 tower kettle (and the junction is connected with the material inlet of the tower kettle Located on the same side of the lower head 3 of the reboiler 2), the other side of the baffle plate 11 is arranged below the material inlet of the reboiler 2 tower kettle (and the connection is located at the lower seal of the reboiler 2 where the material inlet of the tower kettle is located) Opposite side of head 3 side). Setting baffles can further reduce the flow velocity of the material after entering the settling zone, which is conducive to the settlement of large particles of impurities at the bottom of the settling zone. The baffle is detachable and easy to clean, reducing the maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com