Coal based needle coke material pretreatment process

A needle coke raw material and pretreatment technology, applied in coking carbonaceous materials, coking ovens, petroleum industry, etc., can solve problems such as heavy metal infiltration, coking deactivation, and easy deposition on the surface of fixed bed catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

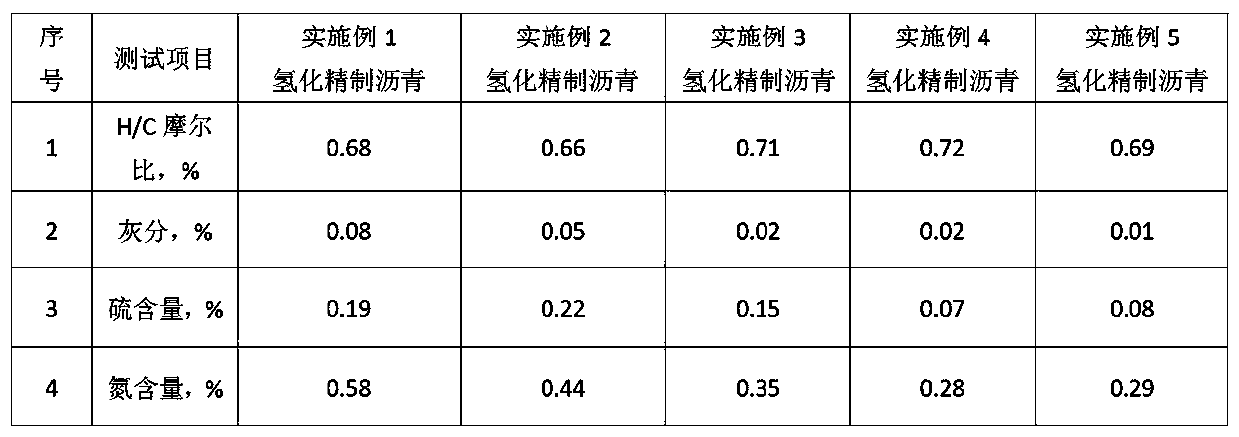

Examples

Embodiment 1

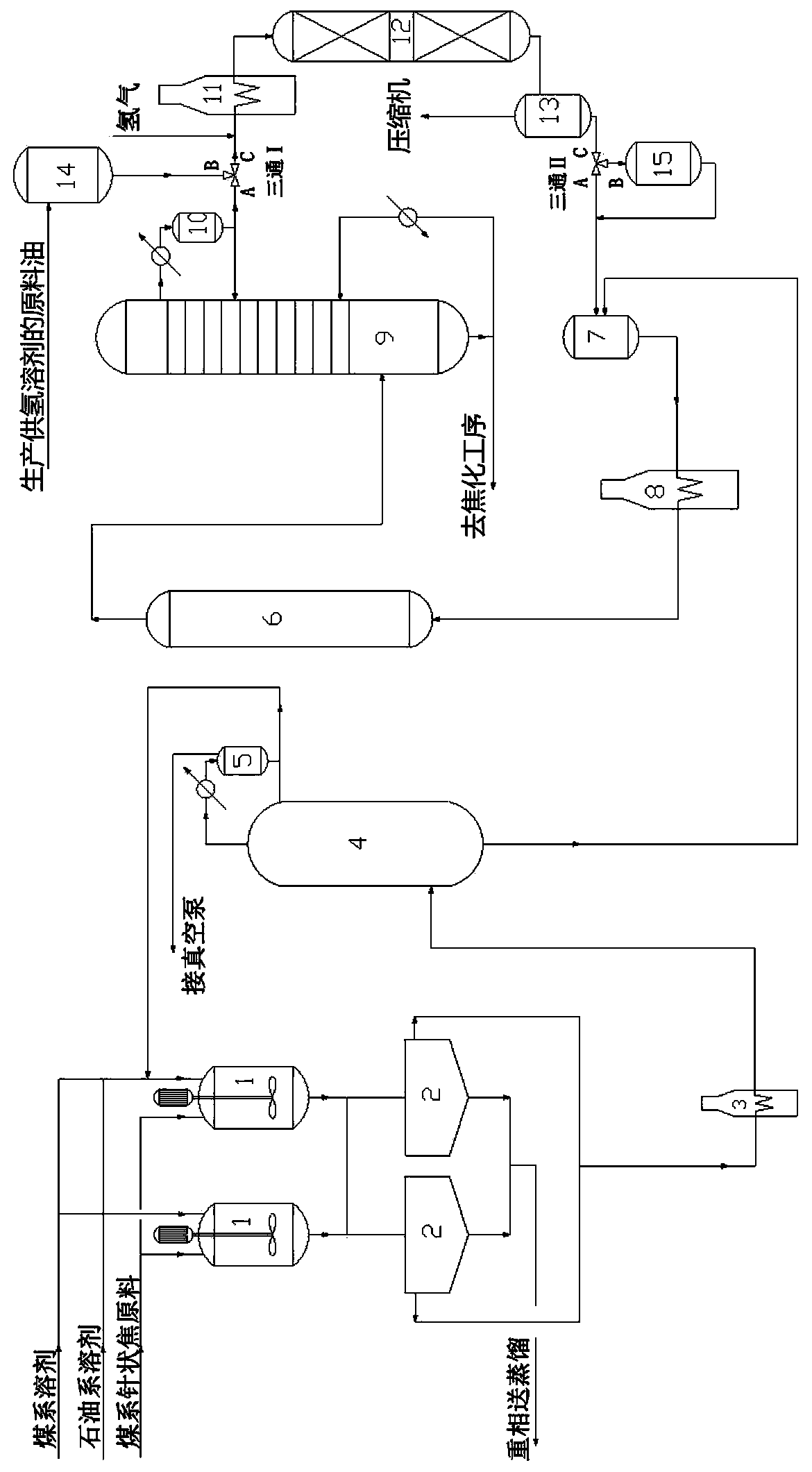

[0027] like figure 1 As shown, a coal-based needle coke raw material pretreatment process, the specific steps are as follows:

[0028] Step 1: Coal tar pitch, benzene and diesel oil are added into the mixing tank 1 according to the ratio of 1:1:1, stirred and mixed in the temperature range of 120°C for 2 hours, and the mixed materials are sent to the settling tank 2 and left to settle for 10 hours;

[0029] Step 2: The mixed material is divided into a heavy phase and a light phase in the settling tank 2, the heavy phase is drawn out from the bottom of the settling tank 2, and the light phase is drawn out from the upper part of the settling tank 2;

[0030] Step 3: The light phase is heated to 180°C through the heating furnace A3, and the heated material is sent to the middle part of the vacuum distillation tower 4 with a vacuum degree of 88%, and the gas phase at the top of the tower at 135°C is cooled by the condenser and then flows into the top tank of the vacuum distillatio...

Embodiment 2

[0038] A coal-based needle coke raw material pretreatment process, the specific steps are as follows:

[0039] Step 1: Coal tar pitch, toluene and diesel oil are added into the mixing tank 1 according to the ratio of 1:1:0.8, stirred and mixed in the temperature range of 120°C for 0.5h, and the mixed materials are sent to the settling tank 2 and left to settle for 8h ;

[0040] Step 2: The mixed material is divided into a heavy phase and a light phase in the settling tank 2, the heavy phase is drawn out from the bottom of the settling tank 2, and the light phase is drawn out from the upper part of the settling tank 2;

[0041] Step 3: The light phase is heated up to 160°C through the heating furnace A3, and the heated material is sent to the middle part of the vacuum distillation tower 4 with a vacuum degree of 85%, and the gas phase at the top of the tower at 115°C is cooled by the condenser and then flows into the top tank of the vacuum distillation tower 5 Inside, a part i...

Embodiment 3

[0049] A coal-based needle coke raw material pretreatment process, the specific steps are as follows:

[0050] Step 1: Add modified asphalt, tetrahydrofuran and cyclohexane into the mixing tank 1 at a ratio of 1:1.5:0.8, stir and mix for 3 hours at a temperature of 150°C, send the mixed material into the settling tank 2 and let it stand Settling for 16h;

[0051] Step 2: The mixed material is divided into a heavy phase and a light phase in the settling tank 2, the heavy phase is drawn out from the bottom of the settling tank 2, and the light phase is drawn out from the upper part of the settling tank 2;

[0052] Step 3: The light phase is heated to 110°C through the heating furnace A3, and the heated material is sent to the middle part of the vacuum distillation tower 4 with a vacuum degree of 80%, and the gas phase at the top of the tower at 100°C is cooled by the condenser and then flows into the top tank of the vacuum distillation tower 5 Inside, a part is used as tower to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com