Manufacturing method for carbon fiber composite plate and self-punching riveting die and method for carbon fiber composite plate and aluminum alloy plate

A composite material plate and aluminum alloy plate technology, which is applied in the field of self-piercing riveting molds and carbon fiber composite material plate preparation, can solve the problems of brittle damage of material plates, reduce the quality of riveted joints, and fail to form riveted joints, etc., and achieve low cost, Excellent shear resistance and fatigue resistance, simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

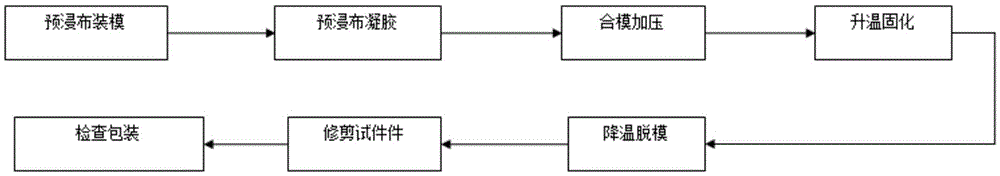

[0069] Fabrication process of carbon fiber composite panels with through holes:

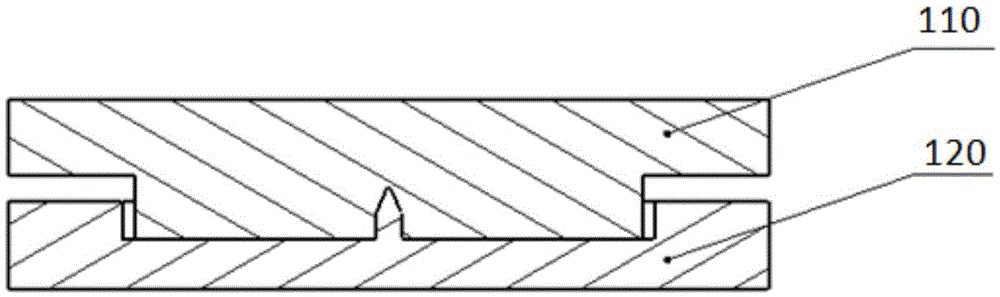

[0070] 1. After the carbon fiber cloth prepreg process is completed, the carbon fiber composite material prepreg cloth is cut, and the prepreg cloth is placed into the groove in the lower die 120. During the laying process, the woven carbon fiber composite material prepreg cloth is The weaving pores of the lower die 120 pass through the beam of light, and ensure that the carbon fiber composite material prepreg is completely paved in the groove, and there is no gap between the bottom surface of the groove and the carbon fiber composite material prepreg;

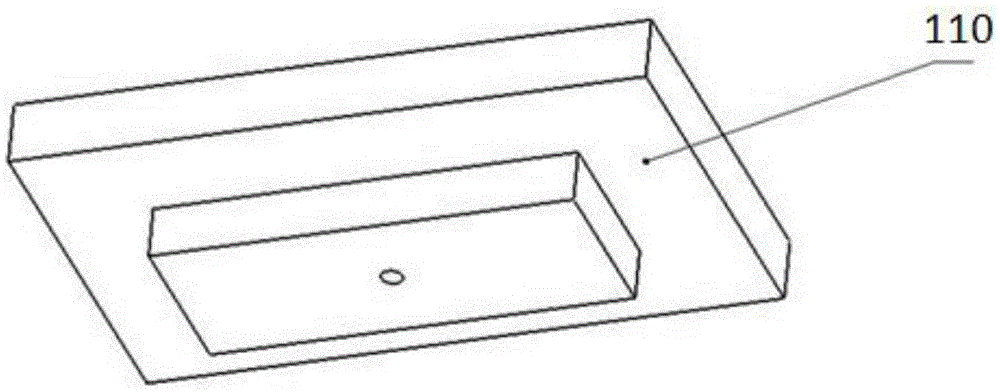

[0071] 2. Assemble the upper punch 110 and the lower die 120 together, and heat the combined mold consisting of the upper punch 110 and the lower punch 120 together to perform prepreg gelation. Taking novolac epoxy vinyl resin as an example, raise the mold clamping temperature to 100°C-110°C to complete the gelation process of the resin;

[0072...

Embodiment

[0138] Apply the method for preparing a carbon fiber composite material plate with a through hole according to the present invention to prepare a central through hole with a diameter of 8mm, and the overall size of the carbon fiber composite material plate is 200mm×80mm×2mm. The base material of the prepared carbon fiber composite board is phenolic epoxy vinyl resin, and the reinforcement material is 3k carbon fiber filament.

[0139] The steps of the self-piercing riveting method between the aluminum alloy plate and the carbon fiber composite plate comprising the preparation process of the carbon fiber composite material plate with through holes described in the present invention are as follows:

[0140] 1. Take an aluminum alloy plate 160 with a thickness of 2mm;

[0141] 2. Prepare a carbon fiber composite material plate 150 with a through hole with a diameter of 8 mm. Cut the prepreg cloth into 8 cuboids with a size of 200 mm × 80 mm, and spread the cut carbon fiber prepr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com