Multi-storey and high-rise CLT wallboard and floorslab connecting structure and method

A connection structure, multi-high-rise technology, applied in the direction of building structure, construction, etc., can solve the problems of transverse grain compression damage and other problems, and achieve the effect of avoiding brittle damage, simple and reasonable shear joints, and good mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

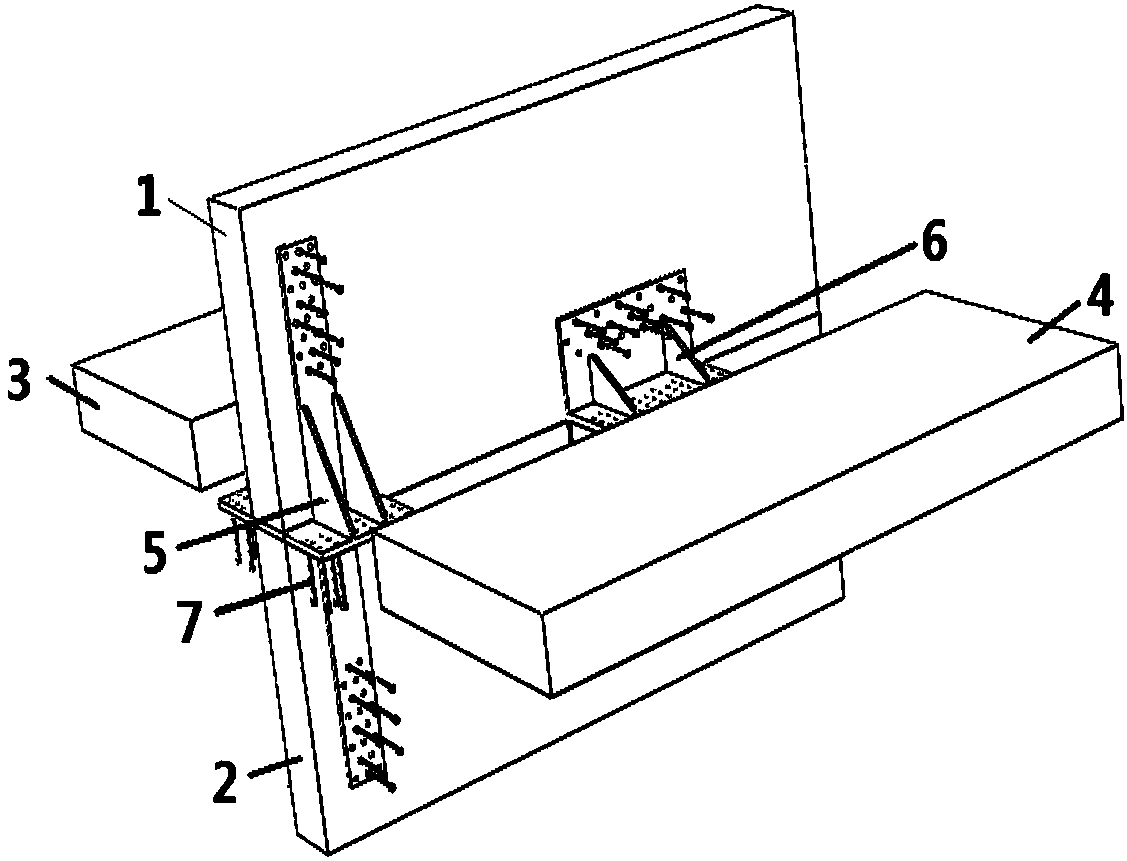

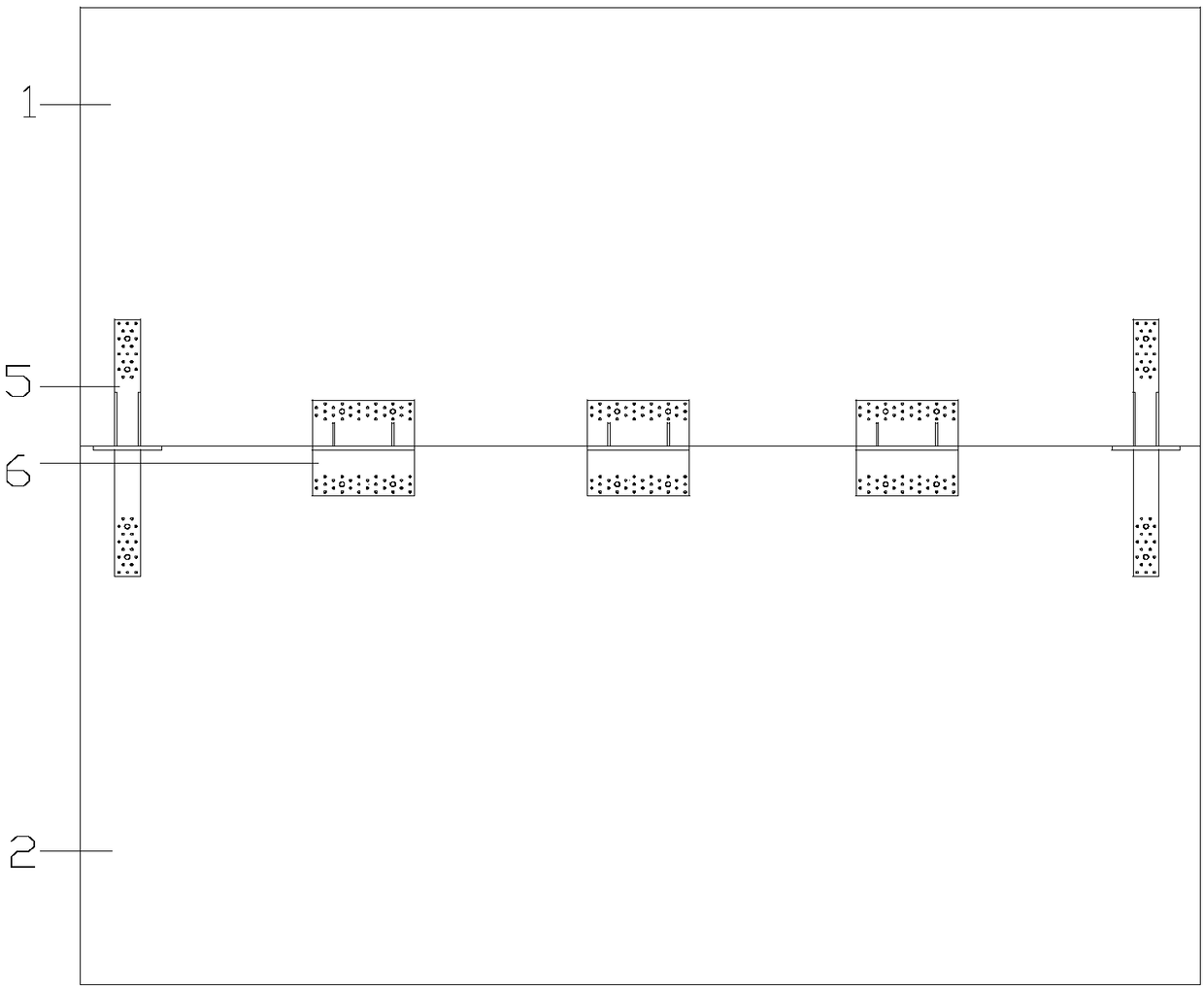

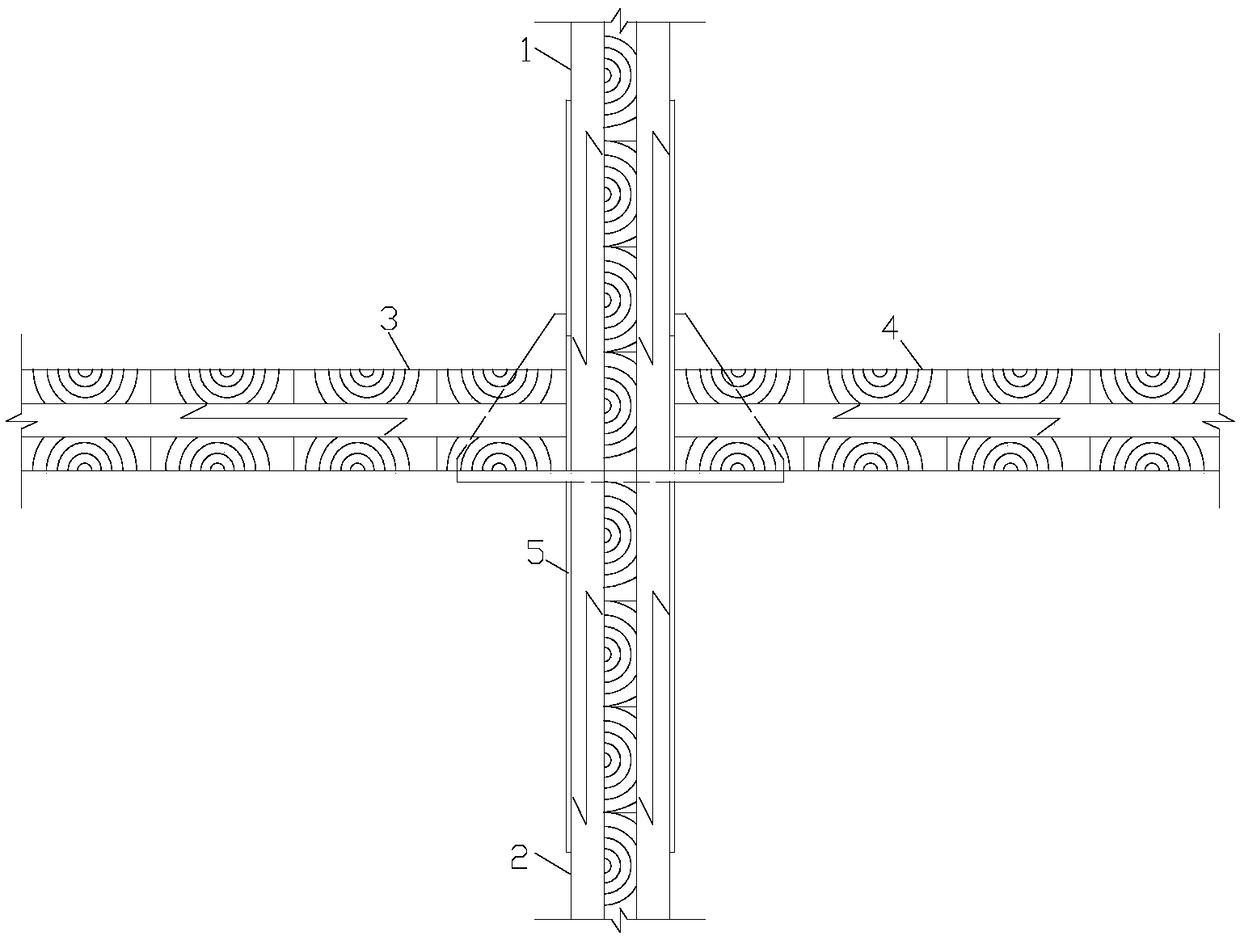

[0033] Such as figure 1 As shown, a multi-high-rise CLT wall and floor connection structure, including cross-glued wood upper wall 1, cross-glued wood lower wall 2, cross-glued wood floor 3, cross-glued wood floor 4, and pullout connections piece 5 and shear connector 6, the cross-glued wood upper wall 1, the cross-glued wood lower wall 2, the cross-glued wood floor 3, and the cross-glued wood floor 4 are composed of the pull-out connector 5, the shear-resistant The connectors 6 are assembled together;

[0034] The anti-pull connector 5 and the shear connector 6 include an upper steel plate 2-1 of the connector, a lower steel plate 2-2 of the connector, a horizontal steel plate 2-3 of the connector, a stiffener 2-4 and a screw hole 2-5, The upper steel plate 2-1 of the connector is two vertical steel plates above the horizontal steel plate 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com