Printing process of high-precision environment-friendly paper box product

A high-precision, carton technology, used in printing, papermaking, transfer materials, etc., can solve problems such as inconvenient cleaning, and achieve the effect of improving convenience and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

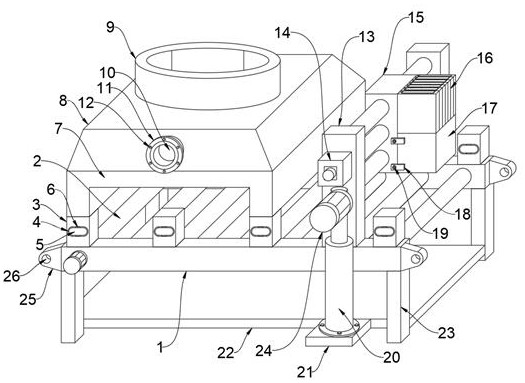

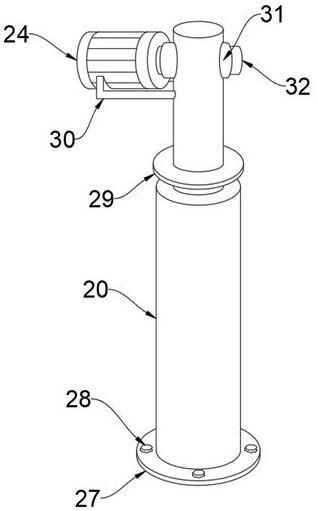

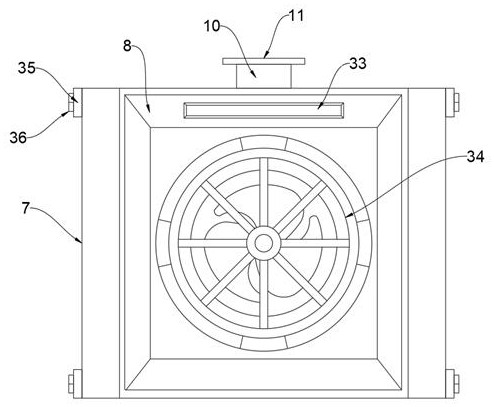

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

[0032] see Figure 1-5 , an embodiment provided by the present invention: the printing process of high-precision environmental protection green carton products, comprising the following steps:

[0033] Step 1: Put the finished carton on the press machine for compression, take it out after one minute of compression, and place it neatly on the mobile shelf;

[0034] Step 2: After placing, move the mobile shelf to the starting end of the conveying mechanism, smooth its surface through the carton surface treatment mechanism, and guide it to move to the printing machine after the surface smoothing treatment;

[0035] Step 3: Use the limit wheel to limit the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com