Bonding and riveting method between carbon fiber composite material plate and aluminum alloy plate

A technology for composite material plates and aluminum alloy plates, which is applied in the field of self-piercing riveting before the cement is cured, and in the field of adhesive riveting devices between carbon fiber composite material plates and aluminum alloy plates, which can solve problems such as adhesive layer damage and avoid Corrosion, improve the joint strength, simplify the effect of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

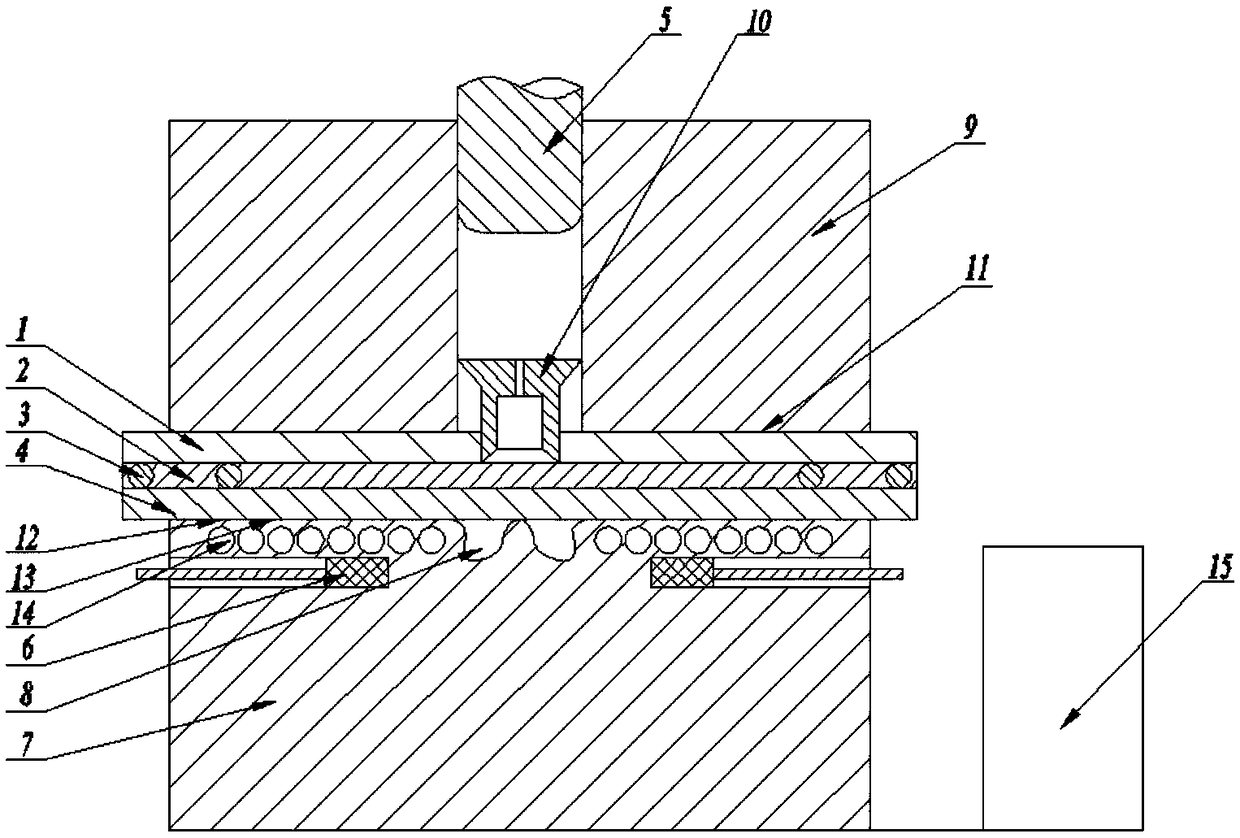

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0045] Such as Figure 3-8 As shown, the self-piercing adhesive riveting connection device provided by the present invention includes: a punch 5 , a thermally conductive electrode 6 , a die body 7 , a die cavity 8 , and a blank holder 9 . The blank holder 9 is arranged opposite to the die main body 7, the center of the blank holder 9 is provided with a through hole, and the bottom surface of the blank holder 9 is contactably connected with the top surface of the die main body 7. The die main body 7 is a disc-shaped structure, and is provided with an annular cavity at the center, which is a concave mold cavity 8. There is a conical boss in the center of the annular cavity. The axes of rotation of the table are collinear.

[0046] On the bottom ring surface of the die main bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com