Assembled frame structure beam-column energy-consumption connecting key

A frame structure and assembled technology, which is applied in the direction of building components, building structures, protective buildings/shelters, etc., can solve problems such as node damage, and achieve the effects of improving bearing capacity, stable and reliable deformation, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

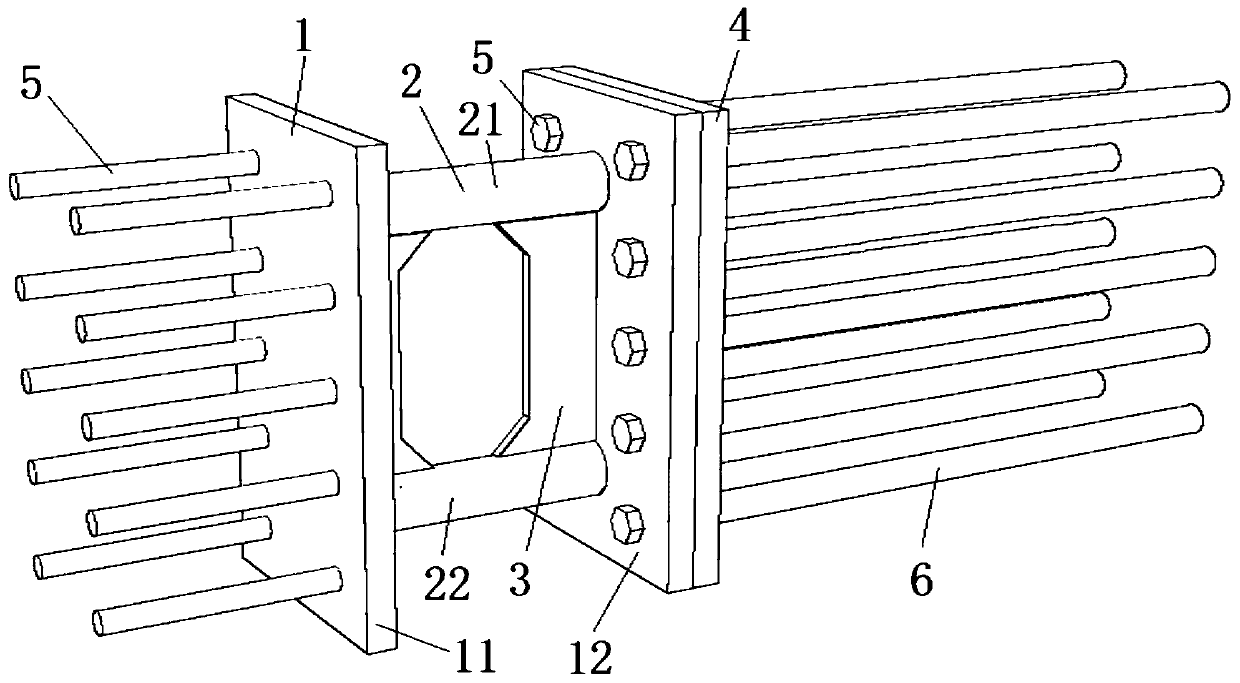

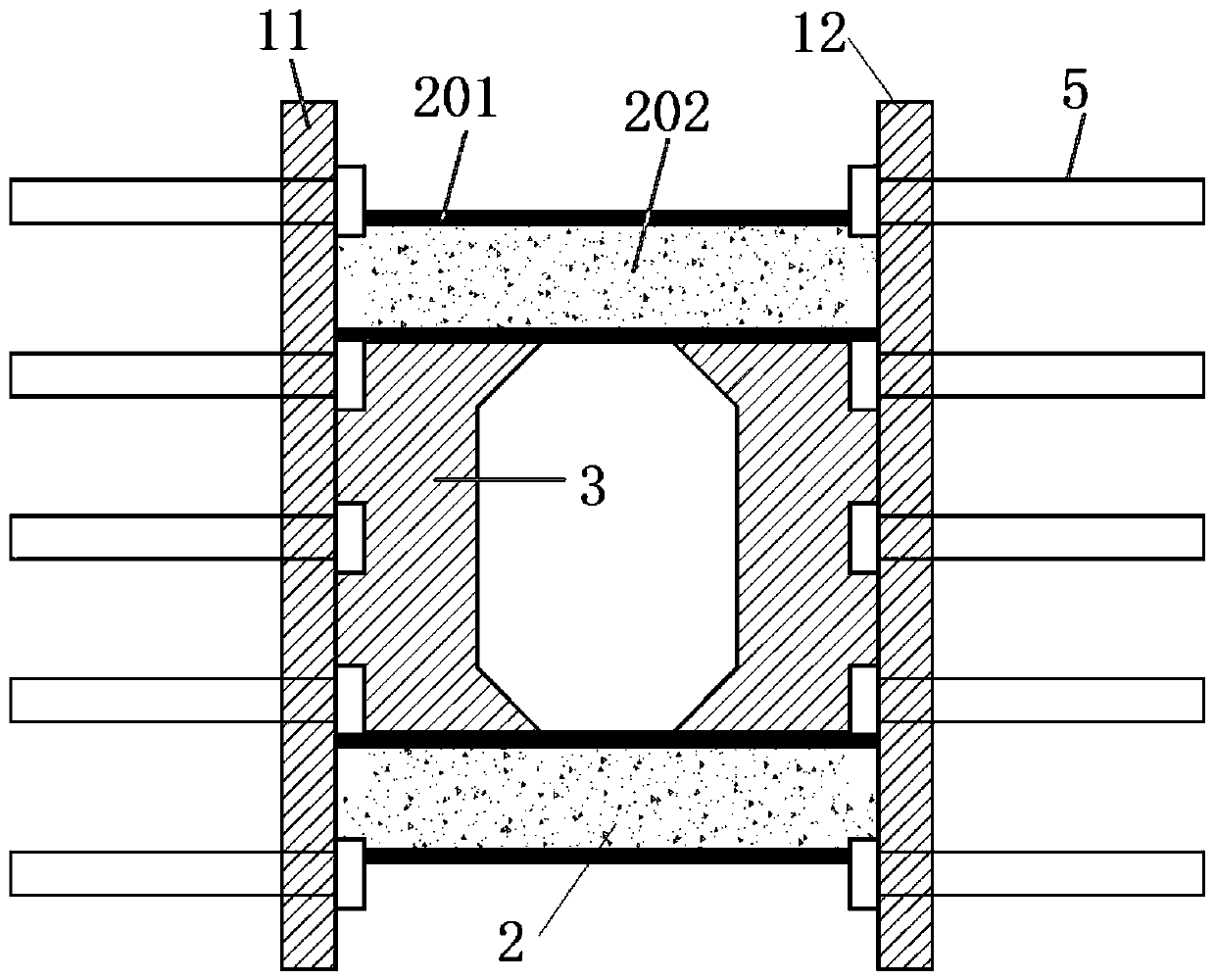

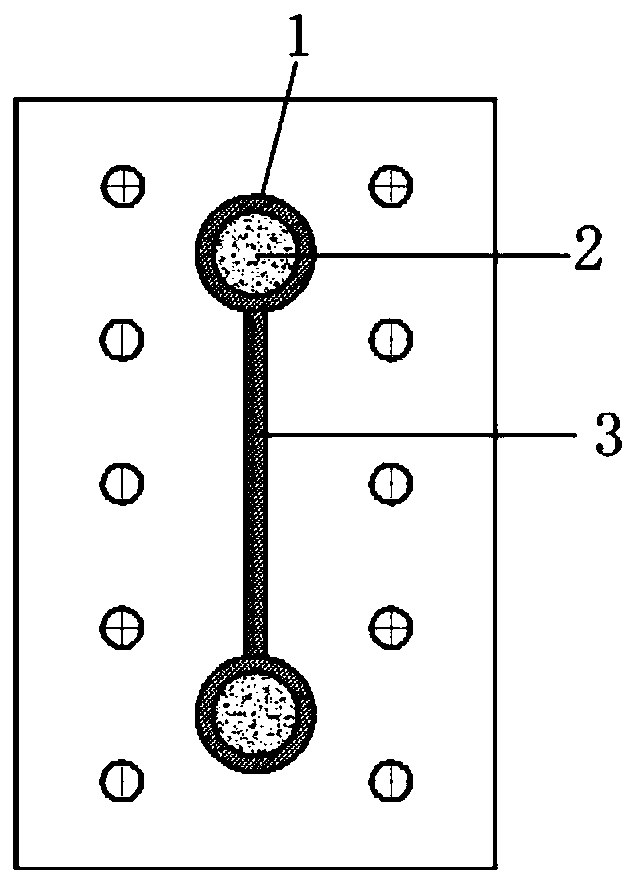

[0036] The present invention provides a prefabricated assembled frame structure beam-column energy-dissipating connection key. The end plate 1 includes two ends arranged in parallel on the first end plate 11 and the second end plate 12, and the steel tube concrete connector 2 is horizontally arranged on the first end. Between the plate 11 and the second end plate 12; the concrete-filled steel pipe connector 2 includes two vertically parallel first concrete-filled steel pipe connectors 21 and second concrete-filled steel pipe connectors 22, and the web 3 is vertically arranged on the first concrete-filled steel pipe concrete Between the connector 21 and the second concrete-filled steel pipe connector 22, the plane where the web 3 is located, the centerline of the first concrete-filled steel pipe connector 21 and the centerline of the second concrete-filled steel pipe connector 22 are located in the same vertical plane; Plate 1, CFST connector 2 and web 3 constitute energy dissip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com