Intelligent production management method for balance-axle bracket through lost-foam casting

A technology of lost foam casting and balanced suspension, applied in foundry workshops, casting equipment, manufacturing tools, etc., can solve problems such as scattered quality control, inability to clearly distinguish process responsibilities, poor traceability of product quality status, etc., to ensure information collection and processing, to achieve controllable and traceable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

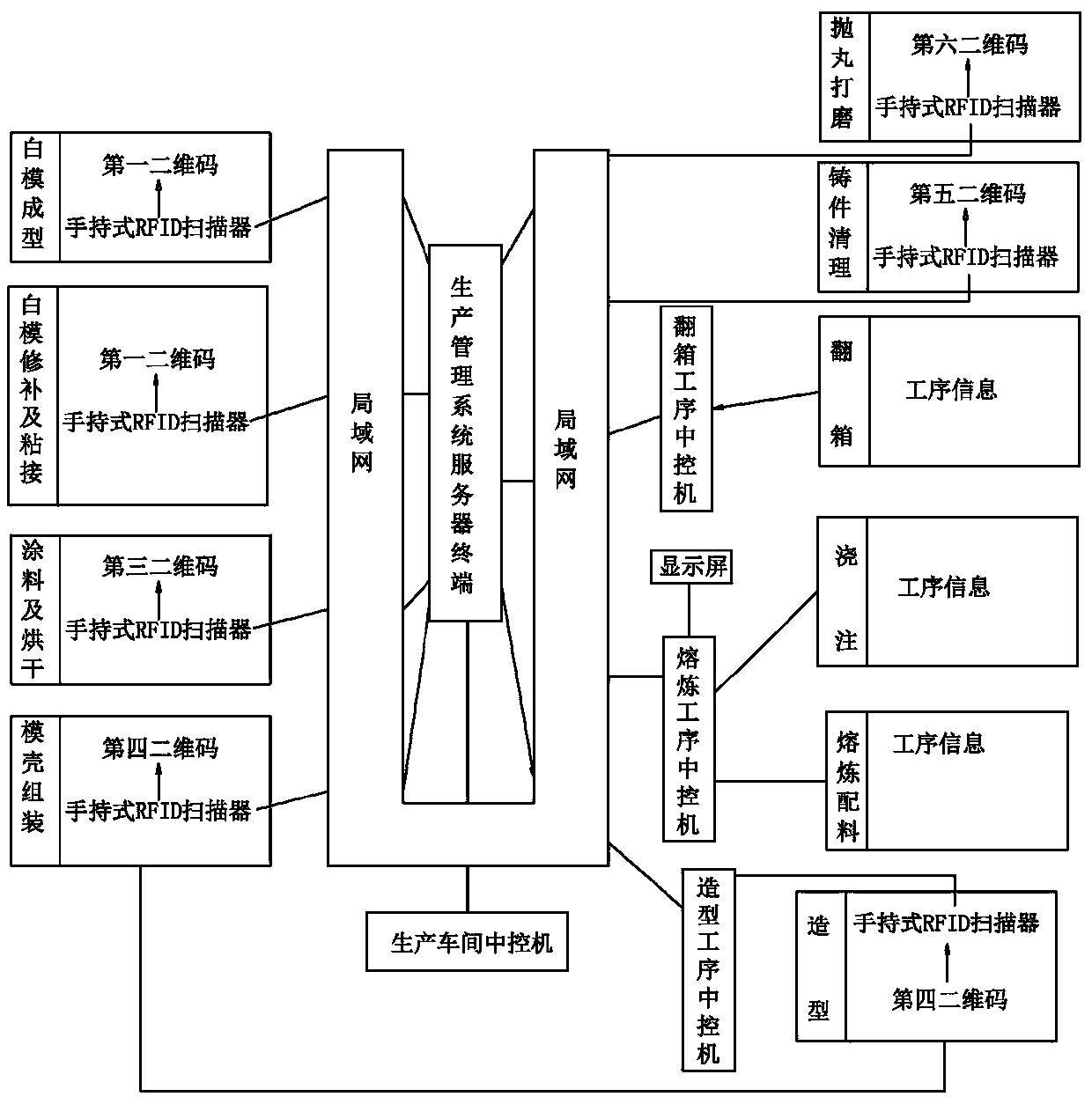

[0030] Below, combined with figure 1 The invention is further described.

[0031] From the perspective of the concept of the invention and wide application, the overall frame-type technical solution adopted by the present invention is: an intelligent production management method for the balanced suspension bracket of lost foam casting, and the production processes involved include manufacturing of lost foam foam models, buried box molding, The specific production management methods for smelting ingredients, pouring, turning over boxes, and cleaning of castings are as follows:

[0032] (1) Product production plan release management

[0033] Use the server terminal of the production management system to publish the product production plan to the central control machine of the production workshop through the local area network;

[0034] (2) Process plan release management

[0035] The production workshop decomposes the product plan into multiple process plans and releases the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com