Waste polypropylene fiber rubber recycled concrete and preparation method thereof

A technology of waste polypropylene and recycled concrete, which is applied in the field of building materials, can solve the problems of low utilization rate and poor performance, and achieve the effects of low cost, enhanced bending and shear performance, and improved ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

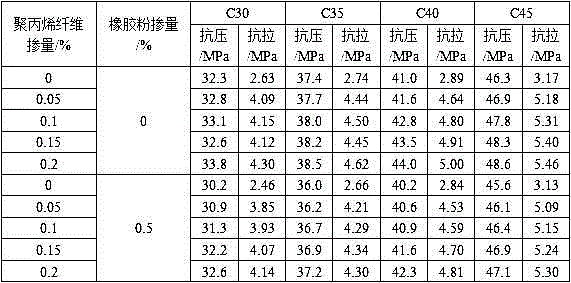

Image

Examples

Embodiment 1

[0024] A waste polypropylene fiber rubber recycled concrete is made from the following raw materials in parts by weight: 3 parts of polypropylene fiber, 8 parts of rubber powder, 378 parts of recycled coarse aggregate, 882 parts of stone, 378 parts of sand, 331 parts of cement, 169 parts of water, 53 parts of admixture, wherein, the effective length of the polypropylene fiber is 5-50 mm, diameter ≥ 0.05 mm, the particle size of the rubber powder is 0.25-3 mm, and the particle size of the regenerated coarse aggregate is 5-30mm, good gradation, the additives are retarder and silica fume.

[0025] The preparation method of the above-mentioned waste polypropylene fiber rubber recycled concrete comprises the following steps: first, dry-mix the polypropylene fiber, rubber powder and sand in a mixer for 30 seconds, so that the polypropylene fiber, rubber powder and sand are fully mixed; Coarse aggregate, stones, cement, water and admixture are placed in a mixer and stirred for 4-5 mi...

Embodiment 2

[0027] A waste polypropylene fiber rubber recycled concrete is made from the following raw materials in parts by weight: 5 parts of polypropylene fiber, 10 parts of rubber powder, 378 parts of recycled coarse aggregate, 882 parts of stone, 455 parts of sand, 405 parts of cement, 160 parts of water, 60 parts of admixture, wherein, the effective length of the polypropylene fiber is 5-50 mm, diameter ≥ 0.05 mm, the particle size of the rubber powder is 0.25-3 mm, and the admixture is a water reducer, Silica fume and nano silica.

[0028] The preparation method of the above-mentioned waste polypropylene fiber rubber recycled concrete comprises the following steps: first, dry-mix the polypropylene fiber, rubber powder and sand in a mixer for 30 seconds, so that the polypropylene fiber, rubber powder and sand are fully mixed; Coarse aggregate, stones, cement, water and admixture are placed in a mixer and stirred for 4-5 minutes, fully stirred; finally the waste polypropylene fiber rub...

Embodiment 3

[0030] A waste polypropylene fiber rubber recycled concrete is made of the following raw materials in parts by weight: 7 parts of polypropylene fiber, 10 parts of rubber powder, 375 parts of recycled coarse aggregate, 875 parts of stone, 483 parts of sand, 468 parts of cement, 155 parts of water, 62 parts of admixture, wherein, the effective length of the polypropylene fiber is 5-50mm, the diameter is ≥0.05mm, and the particle size of the rubber powder is 0.25-3mm.

[0031] The preparation method of the above-mentioned waste polypropylene fiber rubber recycled concrete comprises the following steps: first, dry-mix the polypropylene fiber, rubber powder and sand in a mixer for 30 seconds, so that the polypropylene fiber, rubber powder and sand are fully mixed; Coarse aggregate, stones, cement, water and admixture are placed in a mixer and stirred for 4-5 minutes, fully stirred; finally the waste polypropylene fiber rubber recycled concrete is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com