FRP restrained pipe regenerated mixed concrete combination column

A technology for recycling concrete and concrete, applied in the direction of columns, piers, pillars, etc., can solve the problems of low strength of waste concrete, inability to use fine aggregates, poor strength of composite columns, etc., to overcome easy corrosion, high strength, and avoid brittleness. the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

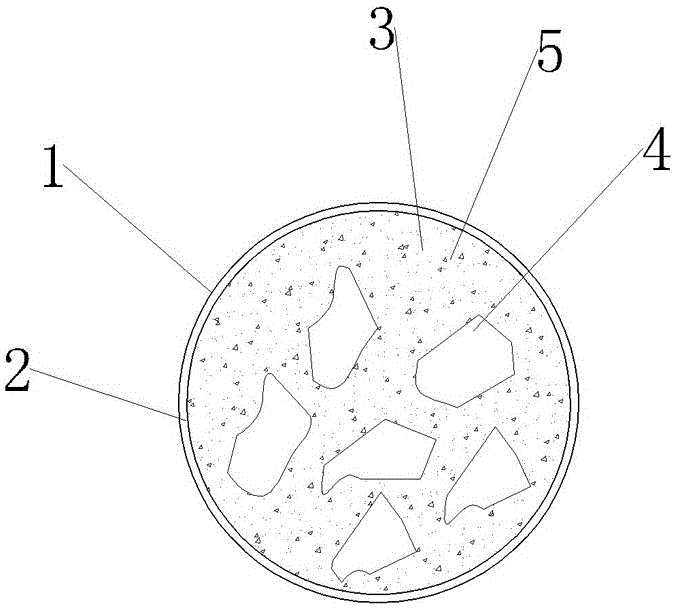

[0010] refer to figure 2 As shown, the FRP-confined pipe recycled concrete composite column provided by the first embodiment of the present invention includes an FRP pipe 1, a steel pipe 2 and a mixture inner core 3, and the mixture inner core 3 includes recycled concrete blocks 4 and freshly mixed Concrete 5 , the mixture inner core 3 is in the steel pipe 2 , the steel pipe 2 is in the inner hole of the FRP pipe 1 , and the FRP pipe 1 clings to and wraps the steel pipe 2 .

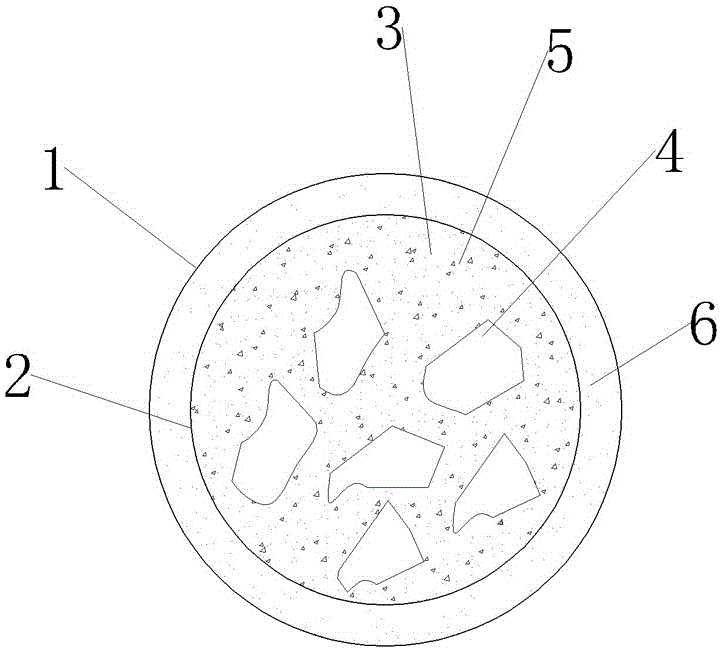

[0011] refer to figure 1 As shown, the second embodiment of the present invention is basically the same as the first embodiment, the only difference is that the following structure is used for replacement: there is a lightweight concrete layer 6 between the FRP pipe 1 and the steel pipe 2, and the lightweight concrete layer is generally Use mortar or fine stone concrete.

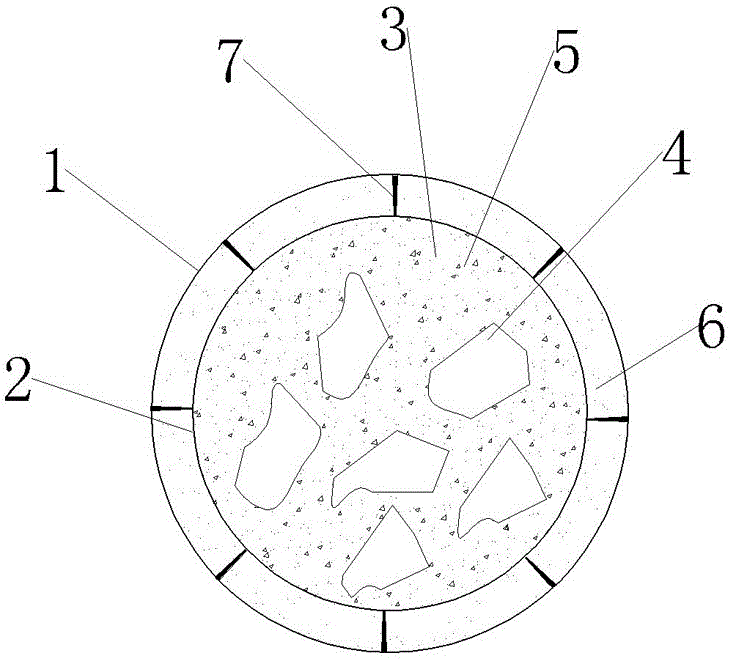

[0012] refer to image 3 As shown, the third embodiment of the present invention is basically the same as the second embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com