Rivetless riveting device and riveting method for dissimilar materials based on hot melting principle

A technology of rivetless riveting and dissimilar materials, which is applied in the field of rivetless riveting devices between dissimilar materials, and can solve the problems of brittle failure and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Mold used for making carbon fiber composite panels with through holes

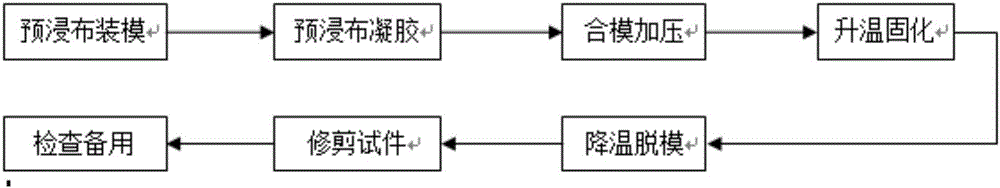

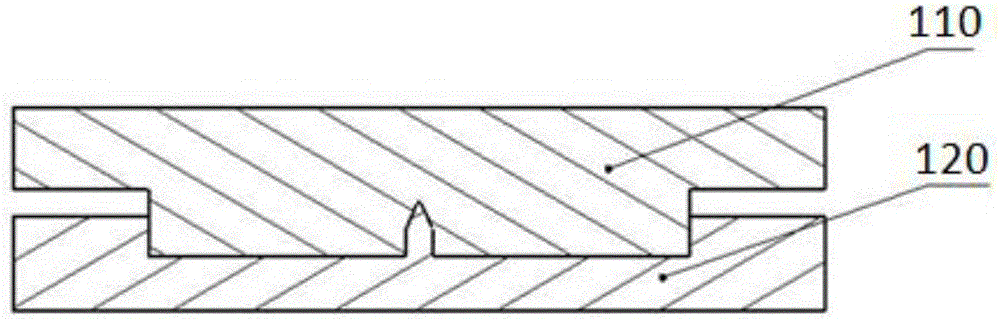

[0072] Such as figure 1 As shown, the carbon fiber composite material molding process includes prepreg mold loading, prepreg gel, mold clamping and pressure, heating and curing, cooling and demoulding, trimming the test piece and checking for backup. The preparation mold is composed of an upper punch 110 and a lower die 120. The mold has a simple structure and is convenient for preparing a carbon fiber composite material plate with through holes.

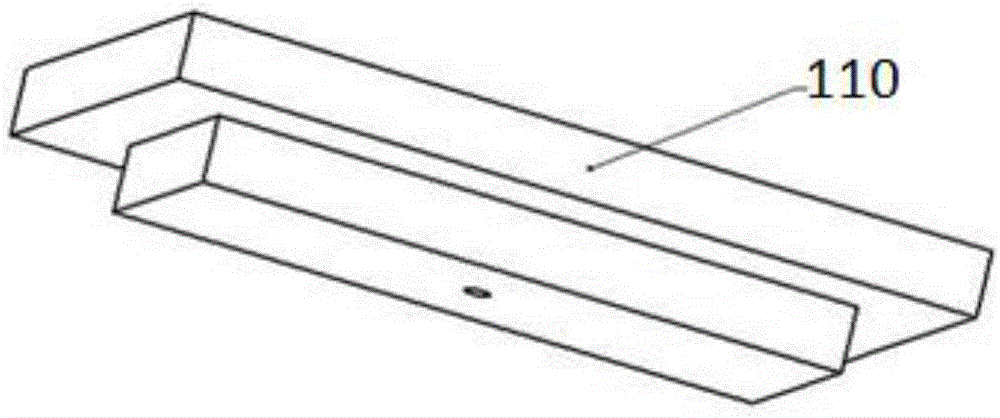

[0073] Such as figure 2 , image 3 As shown, the upper punch 110 is a cuboid structural member, a cuboid boss with relatively small length and width is set at the center with the lower surface of the cuboid as the reference plane, and a cylinder is arranged at the center of the boss Combination of volume and cone light holes, with the bottom surface of the cuboid boss as the reference plane, the light holes close to the reference plane are cylindrical...

Embodiment 2

[0078] Method used to prepare carbon fiber composite panels with through holes

[0079] On the basis of the designed mold, the preparation of the carbon fiber composite plate is realized, and the designed mold can prepare the carbon fiber composite material plate with through holes.

[0080] Fabrication process of carbon fiber composite panels with through holes:

[0081]1. After the carbon fiber cloth prepreg process is completed, the carbon fiber composite material prepreg cloth is cut, and the prepreg cloth is placed into the groove in the lower die 120. During the laying process, the woven carbon fiber composite material prepreg cloth is The weaving pores of the lower die 120 pass through the beam of light, and ensure that the carbon fiber composite material prepreg is completely paved in the groove, and there is no gap between the bottom surface of the groove and the carbon fiber composite material prepreg;

[0082] 2. Assemble the upper punch 110 and the lower die 120 t...

Embodiment 3

[0086] Rivetless riveting method of aluminum alloy plate and carbon fiber composite material plate

[0087] Such as Figure 5 As shown, the rivetless riveting device in the riveting method of the aluminum alloy plate 150 and the carbon fiber composite plate 160 is composed of a hot-melt drill 130 , a blank holder 140 , a riveting needle 170 , and a lower die 180 .

[0088] The hot-melt drill bit 130 is a standard hot-melt drill bit, which consists of an annular boss, a middle cylinder and a top cone structure. A through hole for positioning the hot-melt drill bit 130 is provided at the structure center of the blank holder 140 , and the hot-melt drill bit 130 moves up and down in the through hole of the binder ring 140 during the riveting process.

[0089] The needle body part of the riveting needle 170 is composed of two cylinders with different bottom diameters. Arc surface transition is adopted between bodies. A through hole for positioning the riveting pin 170 is arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| body length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com