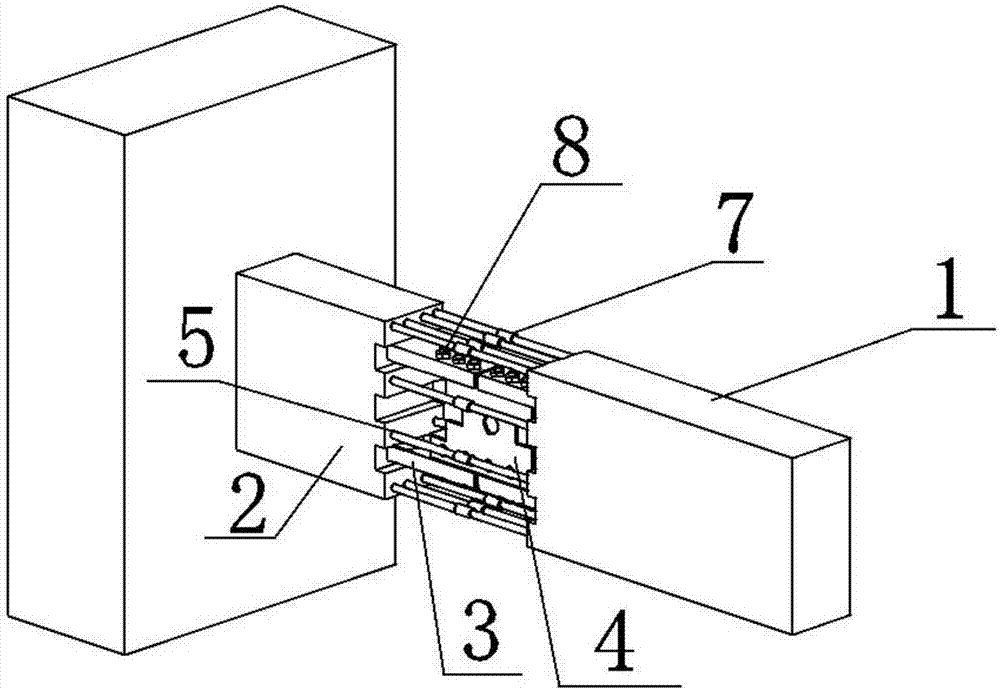

Assembled active beam node of built-in X-shaped low-yield-point type steel connecting piece

A technology with low yield point and connecting nodes, applied in the direction of joists, girders, truss beams, etc., can solve the problems of easy development and penetration of cracks, difficulty in concrete vibrating, difficult pouring and compaction, etc., so as to improve the shear resistance of the interface and improve the ductility. and deformability, the effect of avoiding brittle failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

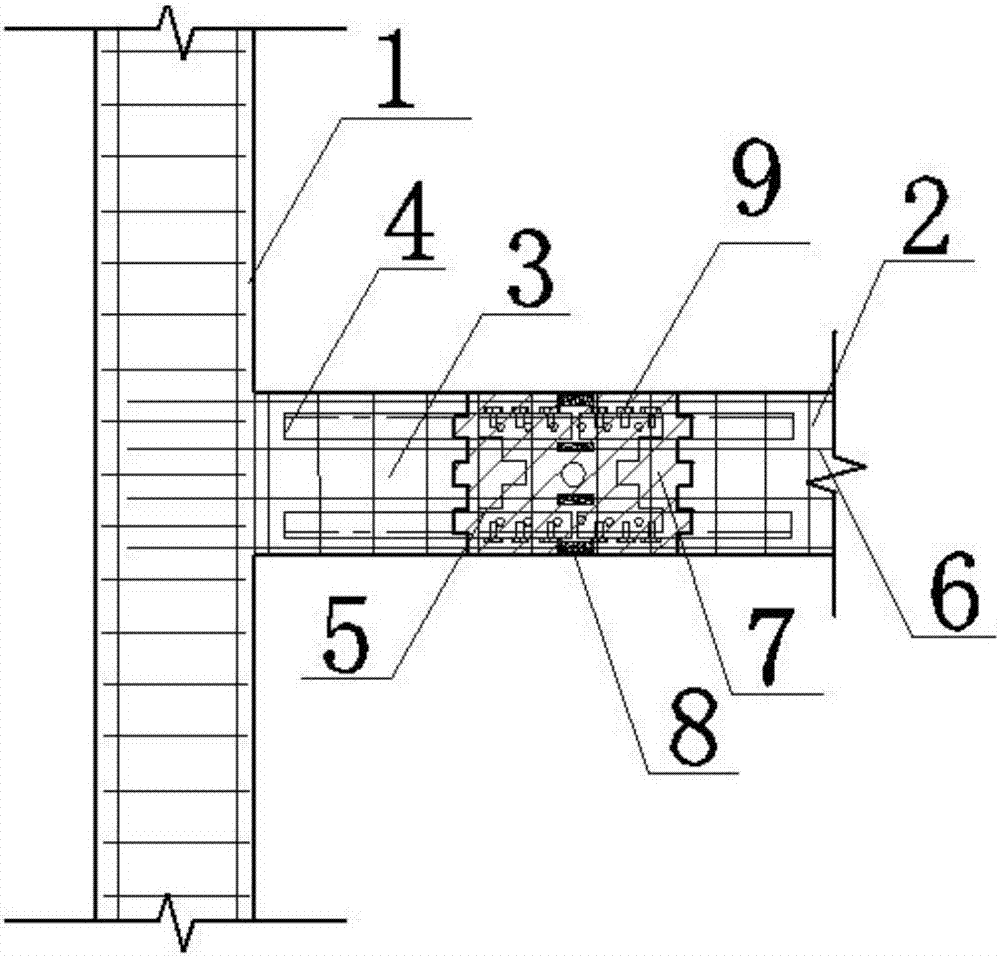

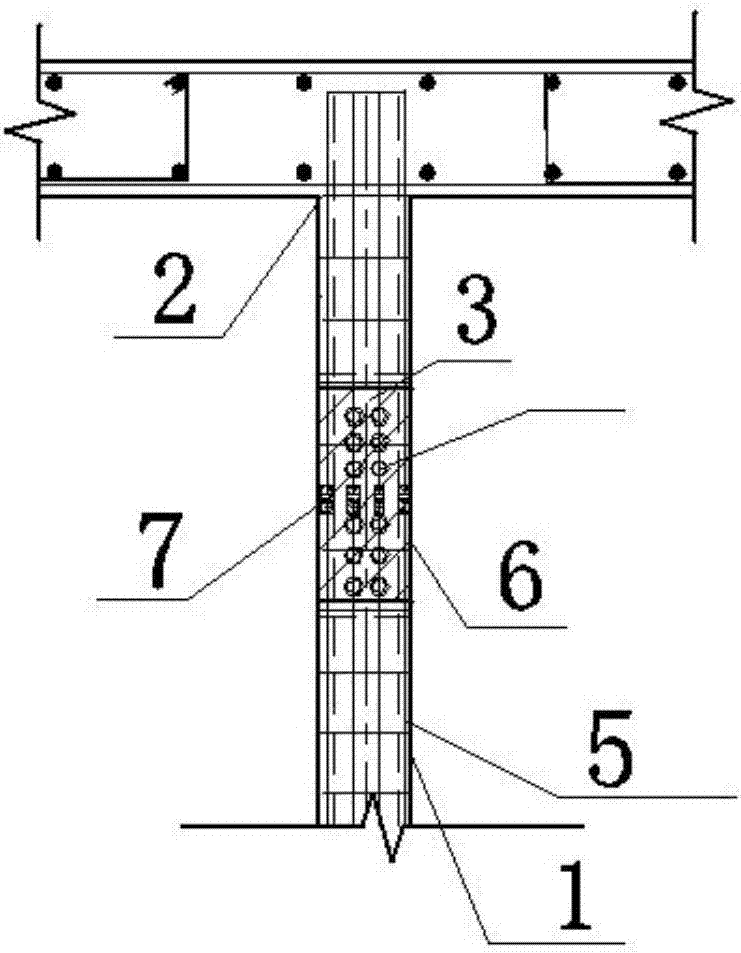

[0034] The specific embodiment of the present invention will be described in detail in conjunction with the accompanying drawings.

[0035] The first stage:

[0036] For a super high-rise reinforced concrete frame-core tube structure, according to the structural design requirements, the prefabricated beam intersects with the shear wall outside the plane, the cross section of the beam is 400mm×900mm, and the beam span is 10m. For HRB400, determine that the extension length of the connecting section 3 is 1000mm, the width is 400mm, the length of the post-casting section is 1000mm, and the part in contact with the post-casting node is set with a horse-toothed bar, and the connecting steel bars are arranged in the 3rd, and the labels and diameters of the steel bars They all correspond to the ordinary stressed steel bars in the prefabricated beam one by one, the upper and lower longitudinal bars and torsion-resistant waist bars all protrude 500mm from the beam plane, and the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com