Temperature stress releasing structure of large-size steel structure building

A technology of temperature stress and steel structure, applied in the direction of building structure, construction, etc., can solve the problems of temperature stress and temperature deformation, and achieve the effect of avoiding brittle failure, avoiding joint structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention.

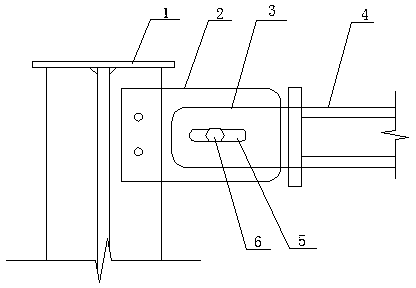

[0011] see figure 1 , this large-scale steel structure building temperature stress relief structure, its structural parts include a steel frame beam 1 and a longitudinal member 4, a connection end plate 3 is welded on the longitudinal member 4, and a connection end plate 3 is fixed on the reinforcement rib of the steel frame beam 1 The splint 2, the connecting end plate 3 and the connecting splint 2 are respectively provided with corresponding longitudinal oblong holes 5; The oblong holes 5 are connected by slidable bolts 6 .

[0012] The above-mentioned longitudinal members 4 mainly include purlin wall beams, crane beams and other members. The wall panels are processed into a stretchable structure, and the entire plant structure can release temperature stress through the sliding and stretching of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com