Cover parts for internal combustion engines

A technology for cover parts and internal combustion engines, which is applied in the direction of engine components, lubricating parts, engine lubrication, etc., can solve the problems of increased weight of the chain cover, and achieve the effects of weight reduction, vibration suppression, and efficient lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

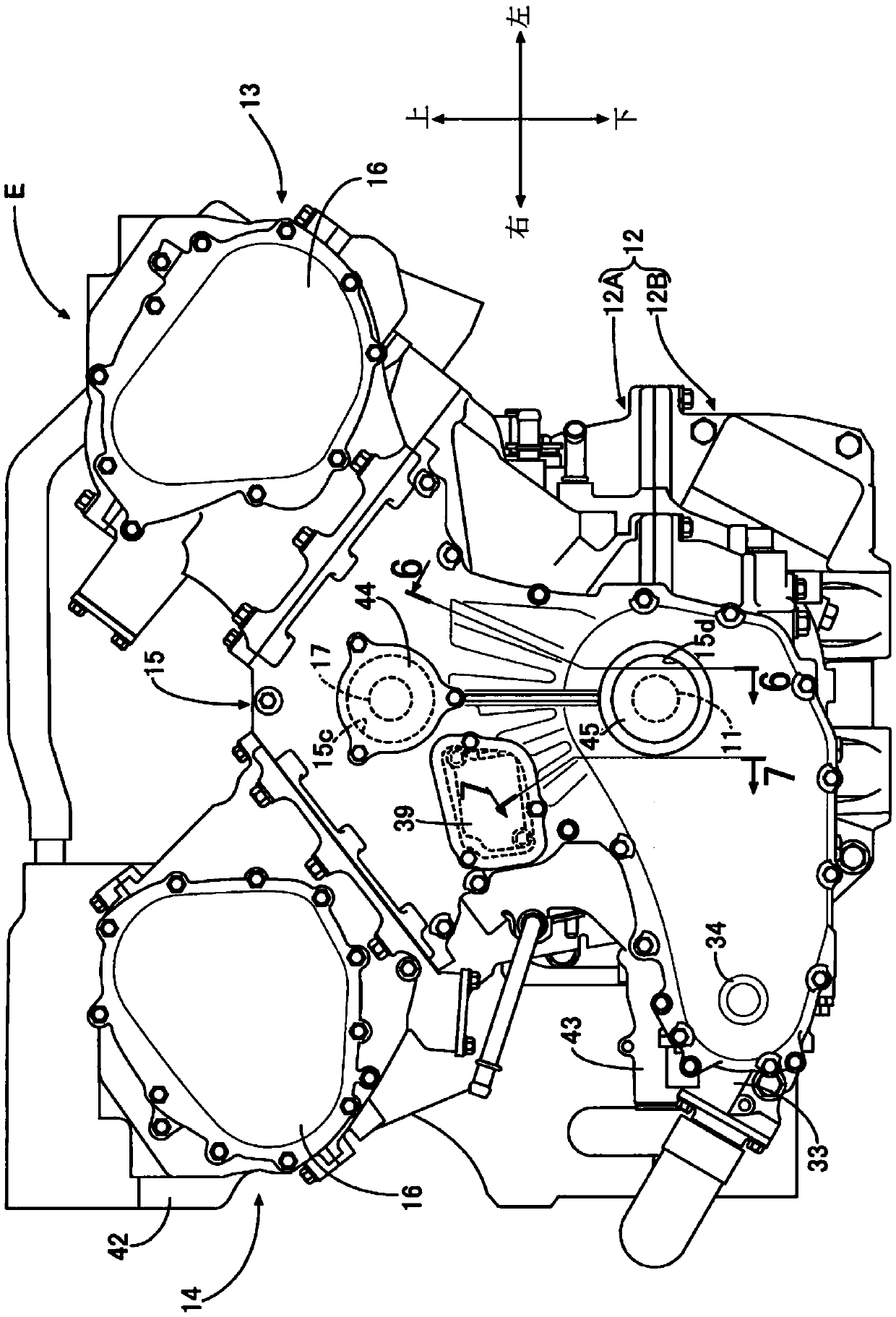

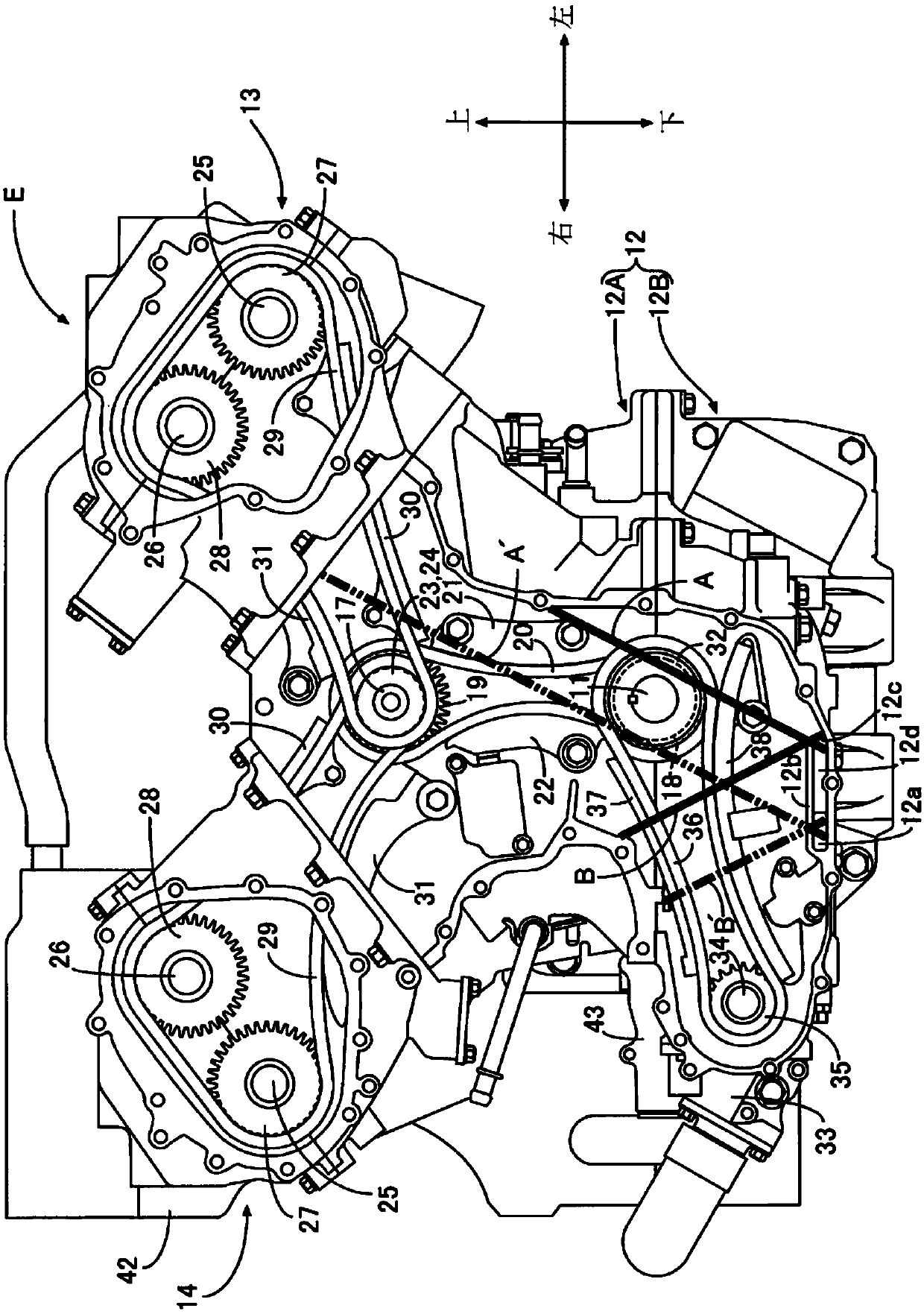

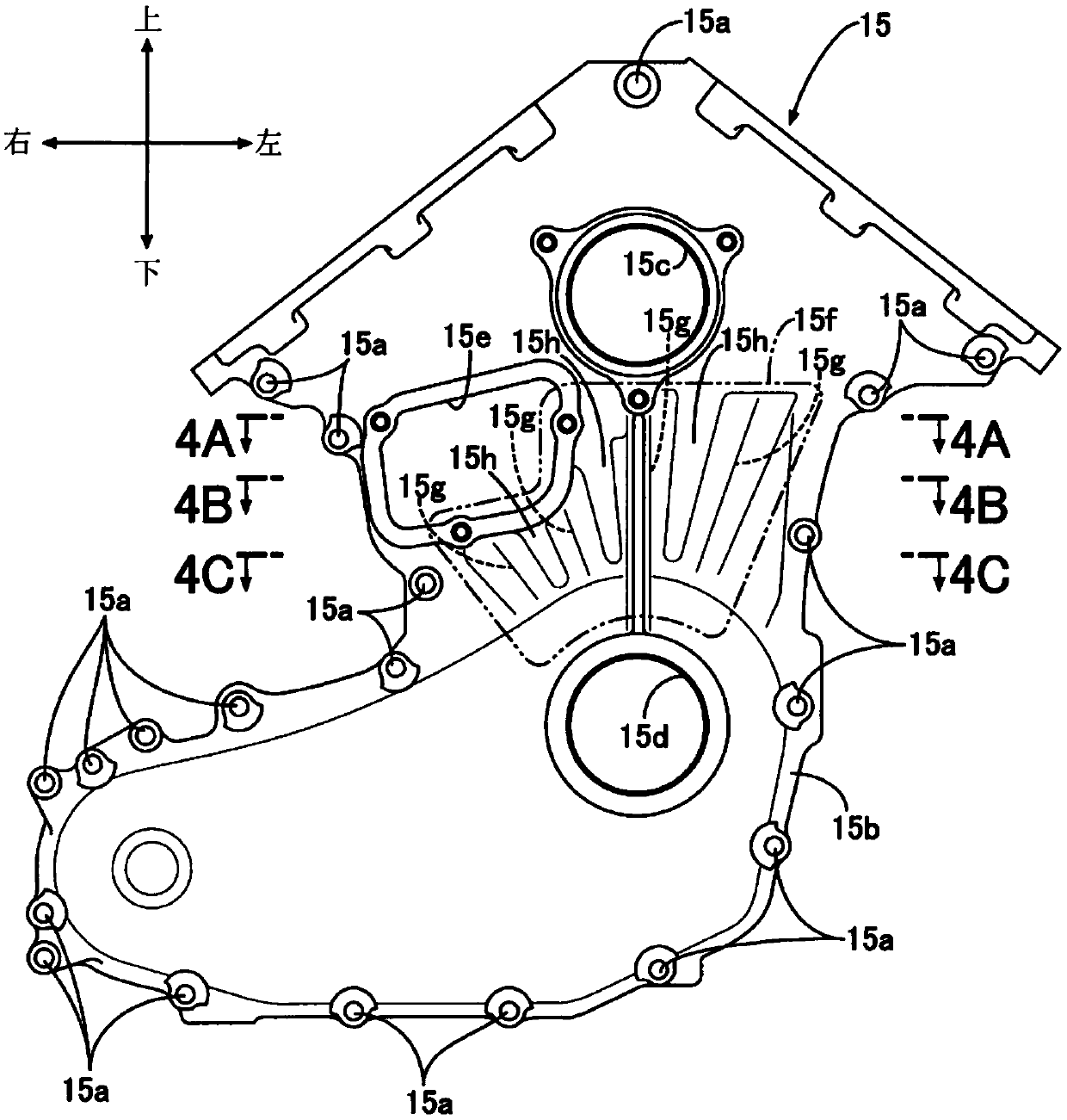

[0025] Below, according to Figure 1 to Figure 7 Embodiments of the present invention will be described. The front-back direction, left-right direction, and up-down direction in this manual are defined based on the driver sitting in the driver's seat.

[0026] Such as figure 1 as well as figure 2 As shown, the V-type multi-cylinder internal combustion engine E is mounted on the vehicle body so that the axis of the crankshaft 11 is along the front-rear direction, and the crankcase 12 is formed by integrating the crankcase upper half 12A and the crankcase lower half 12B In this configuration, the left cylinder 13 and the right cylinder 14 protrude obliquely upward in a V shape from the upper portion of the crankcase upper half 12A. The front surface of the crankcase 12 is covered with a detachable main chain cover 15 , and the front openings of the left and right cylinders 13 , 14 are covered with detachable sub chain covers 16 , 16 , respectively.

[0027] The crankshaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com