A lubricating device with a turntable oil separator for large equipment

A technology for large-scale equipment and lubricating devices, applied in distribution devices, engine lubrication, mechanical equipment, etc., can solve the problems of low degree of intelligence, no oil separator structure, and inability to detect the temperature of the lubricating point. Efficient, avoid underfilling, accurate on-off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

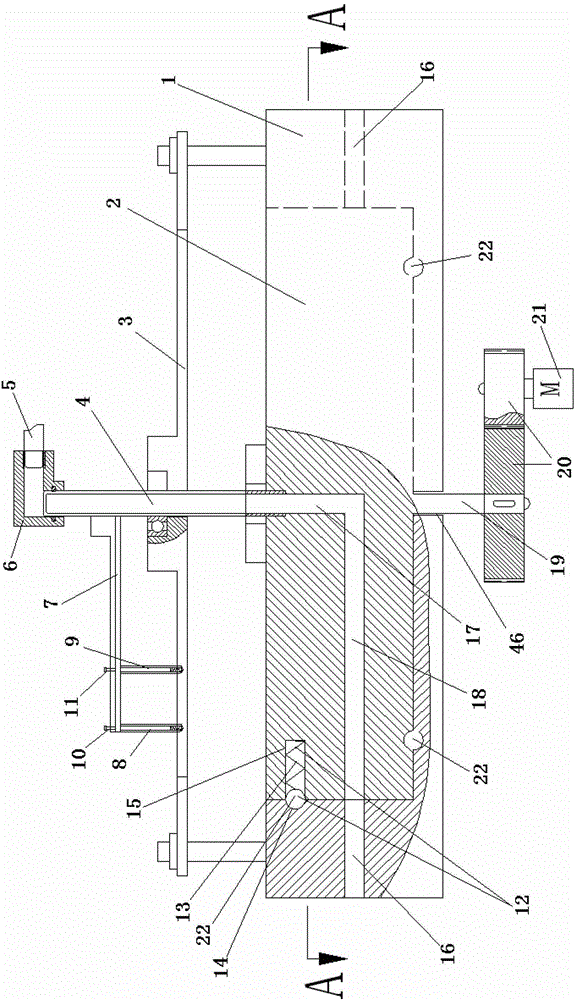

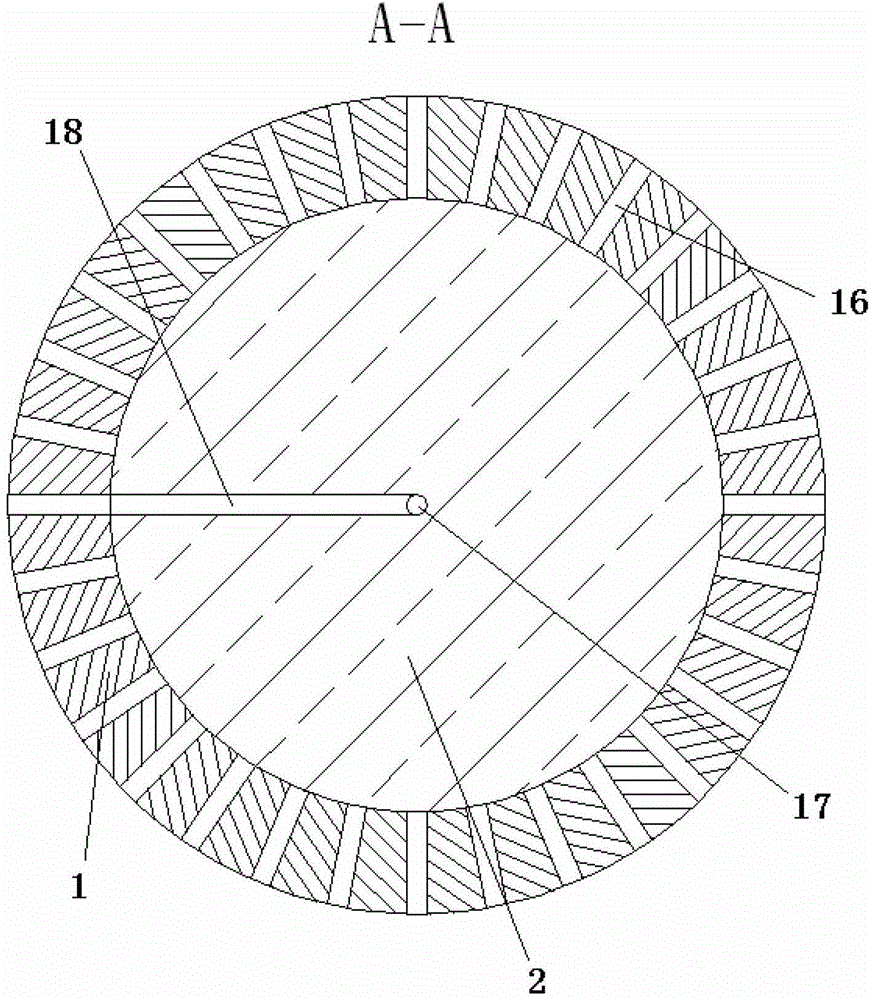

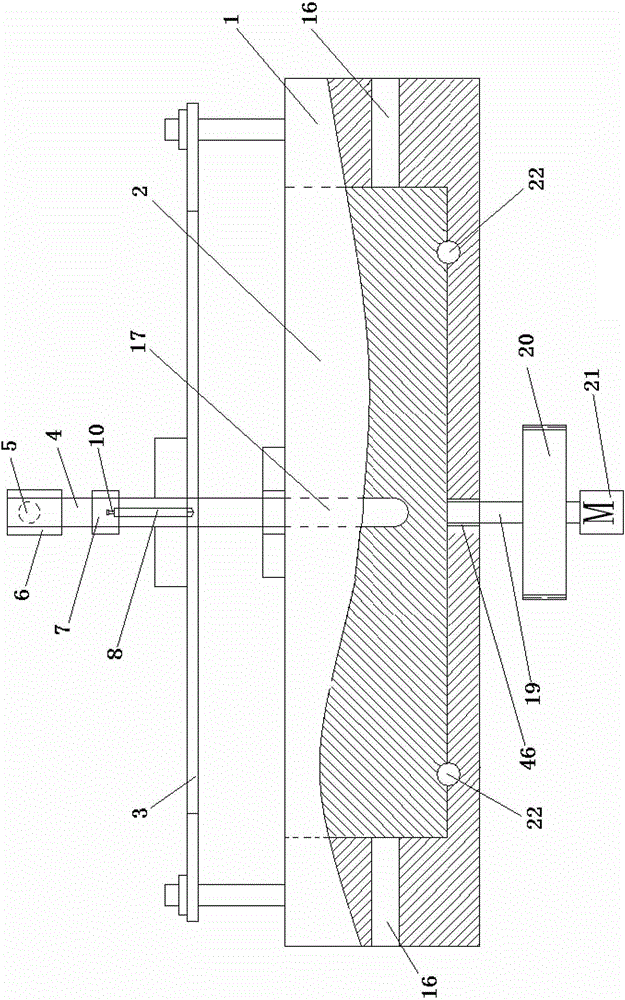

[0035] Comply with the above technical solutions, such as Figure 1 to Figure 6 As shown, this embodiment provides a lubricating device with a rotary disc oil separator for large equipment, including a lubricating oil filling hydraulic unit 25, and the lubricating oil filling hydraulic unit 25 includes at least a lubricating oil tank 27, An oil filter 28 is installed in the lubricating oil tank 27, and the oil filter 28 is connected with the hydraulic pump 29. The DC motor 30 is installed on the hydraulic pump 29 to drive the hydraulic pump 29. The solenoid valve 33 is connected, and a relief valve 32 is arranged on the oil deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com