LED print-head and producing method thereof, and methof for producing LED substrate and pasting method thereof

A technology of LED substrate and manufacturing method, which is applied in the direction of printing, electrical components, circuits, etc., can solve the problems of position deviation of luminous point, deterioration of printing quality, easy warping, etc., achieve sufficient strength, improve reliability, and improve durability The effect of bending deformation and heat deformation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

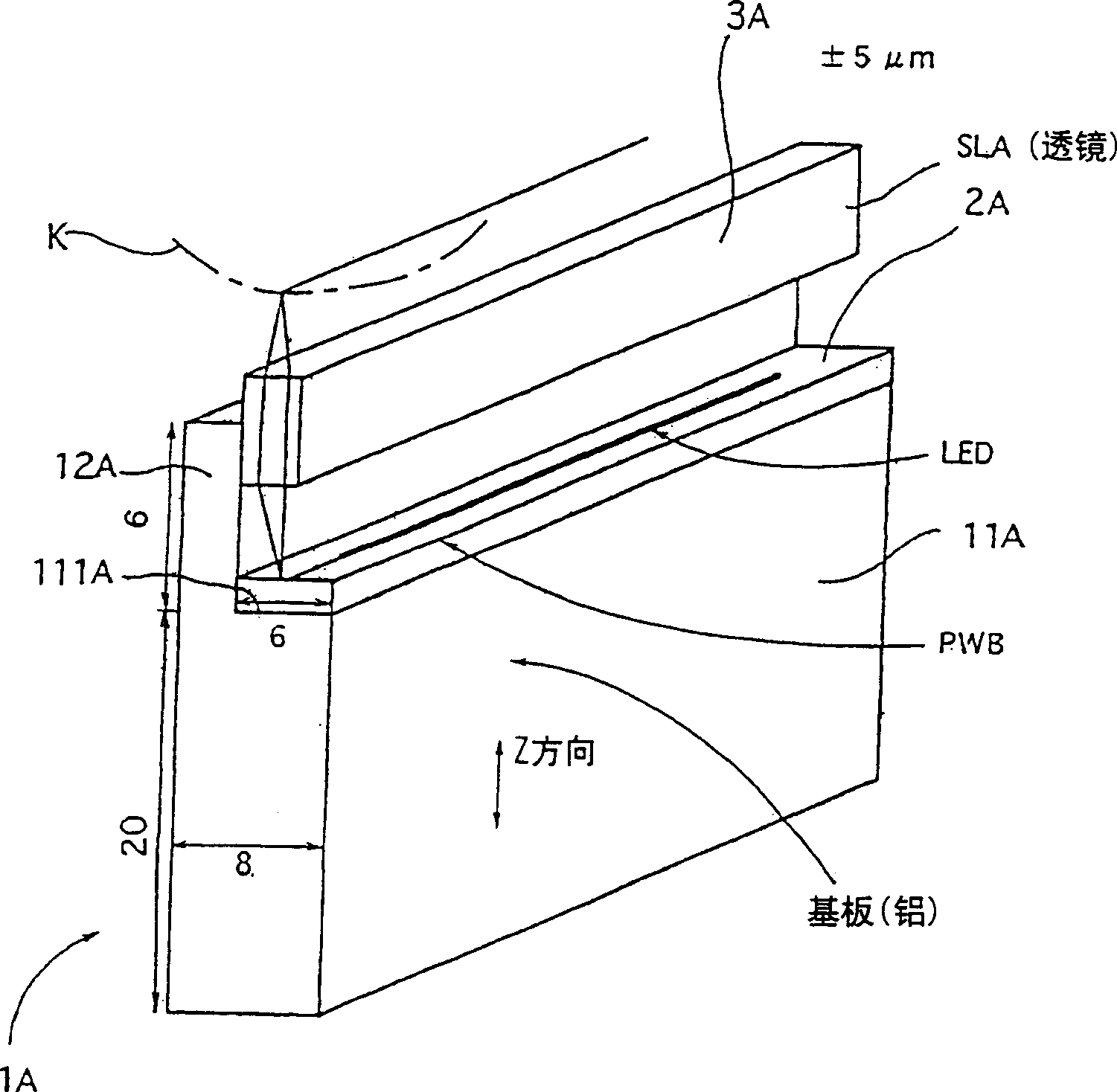

[0100] The LED printing head of this embodiment 1, such as figure 1 As shown, it is composed of a base body 1A disposed opposite to the photosensitive drum K, an LED substrate 2A disposed on the base body 1A, and a lens array 3A. Among them, the base body 1A extends parallel to the axial direction of the photosensitive drum K, and is composed of a large-capacity base portion 11A and a small-capacity protruding portion 12A. The large-capacity base portion 11A is formed opposite to the photosensitive drum K. Surface 111A; the small-capacity protrusion 12A protrudes and extends upward from the above-mentioned facing surface 111A side of the base portion 11A, and is integrally formed. The LED substrate 2A is arranged on the facing surface 111A of the base portion 11A. The lens array 3A is disposed at one end of the protruding portion 12A at a predetermined location between the outer peripheral surface of the photosensitive drum and the upper surface of the LED substrate 2A. The cross...

Embodiment approach 2

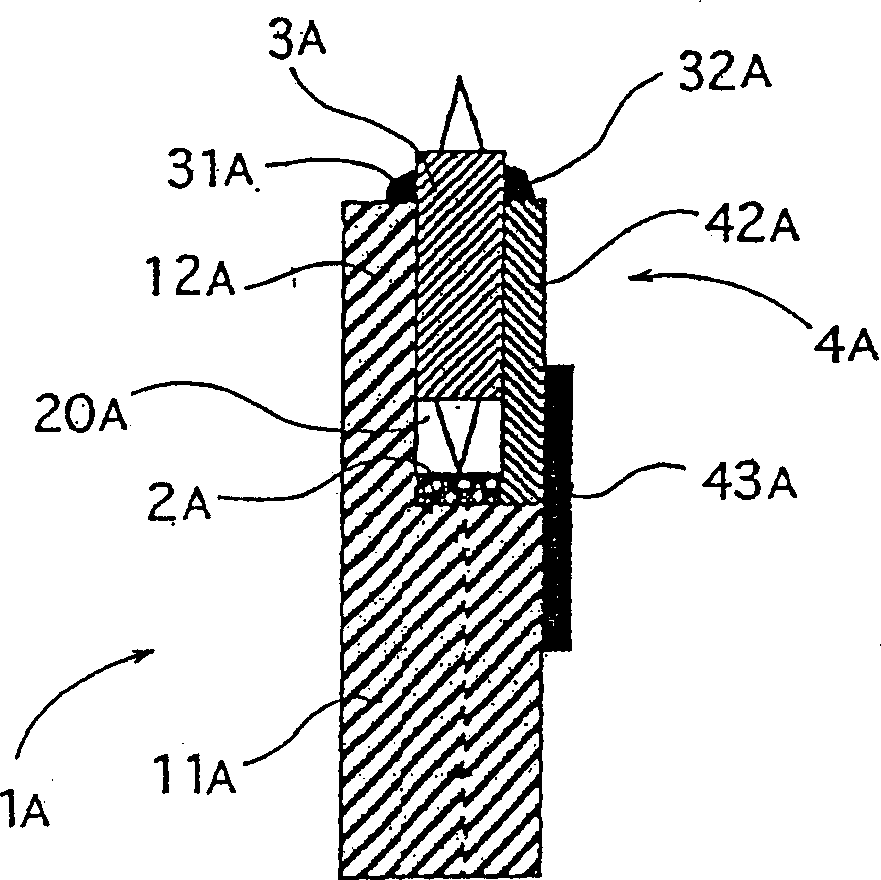

[0118] The LED printing head of this embodiment 2, such as figure 2 As shown, the part of the sealing member 4A that blocks the space 20A between the lens array 3A and the LED substrate 2A is added. This point is different from the above-mentioned first embodiment. The following description focuses on the difference, and the same part is labeled Symbol and description is omitted. The dimensions of each part are the same as in the first embodiment.

[0119] The sealing member 4A is composed of a thin-walled polycarbonate resin and other resin-made shielding members 42A, one end of which faces the other side surface of the lens array 3A on the side surface of the tip portion of the protruding portion 12A, and is sealed by a sealing material 32A and is Fixed; the other end facing the side wall of the base part 11A is sealed by aluminum tape 43A.

[0120] In the LED print head of the second embodiment configured as described above, in addition to the effects of the first embodiment, ...

Embodiment approach 3

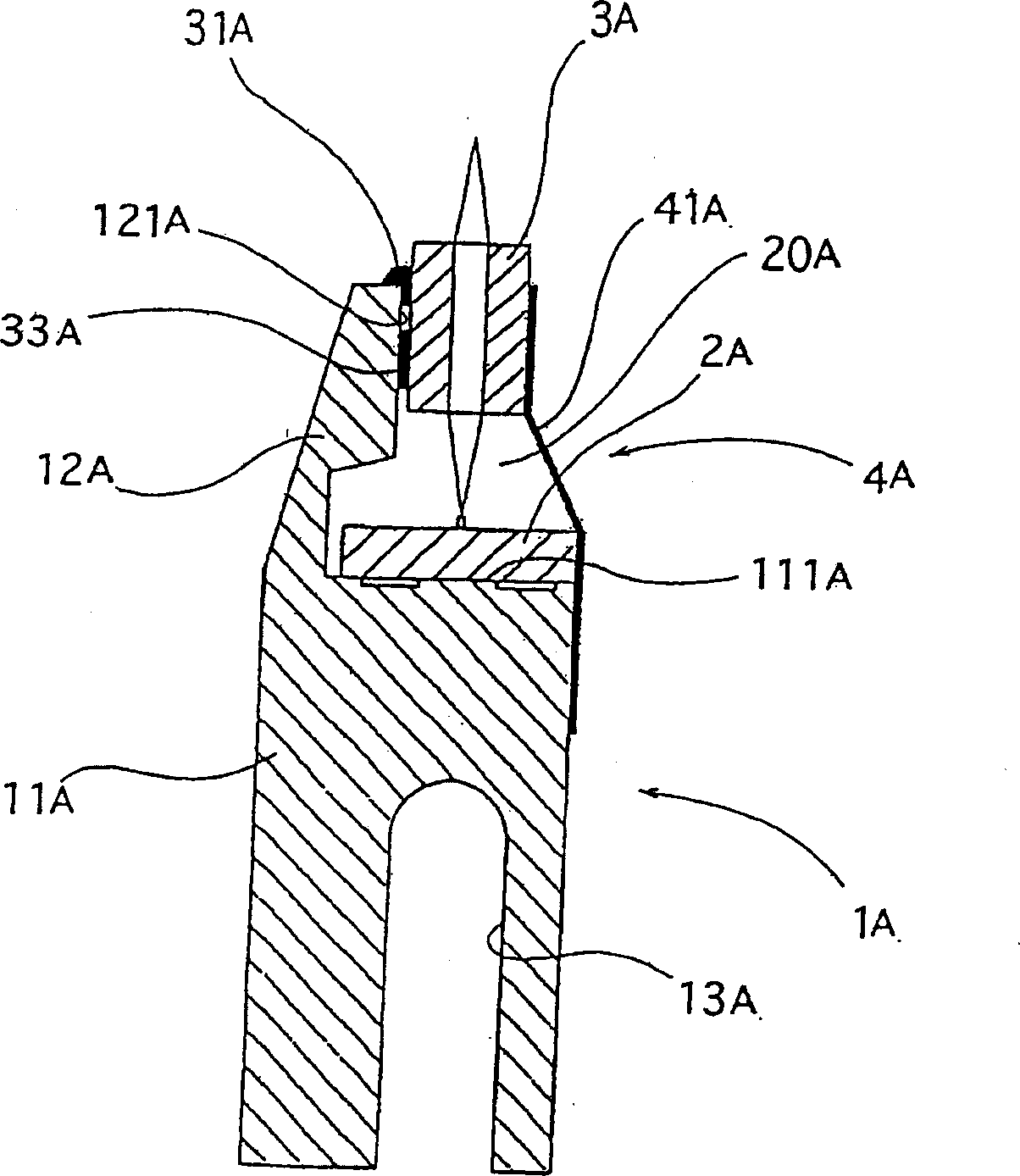

[0122] The LED printing head of this embodiment 3, such as image 3 As shown, a closing member 4A that closes the space between the lens array 3A and the LED substrate 2A is added, and a slightly U-shaped cutout 13A is added to the above-mentioned base part, which differs from the above-mentioned embodiment in these two points 1. The description is centered on the difference, and the same part is marked with the same symbol to omit the description.

[0123] The base portion 11A is composed of a rod-shaped member that extends parallel to the axial direction of the photosensitive drum, and is composed of an aluminum material having a rectangular cross-section with a width of 13.8 mm and a height of 26.5 mm; and on the base portion 11A A horizontally facing surface 111A on which the LED substrate 2A facing the photosensitive drum is arranged is formed.

[0124] In the lower part of the above-mentioned base part 11A, in order to increase the heat radiation area, a cutout part 13A havi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com