Liquid crystal display panel and manufacturing method thereof as well as display device

A technology for a liquid crystal display panel and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of light leakage, scratched PI film, position shift, etc. The effect of force, contact area density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

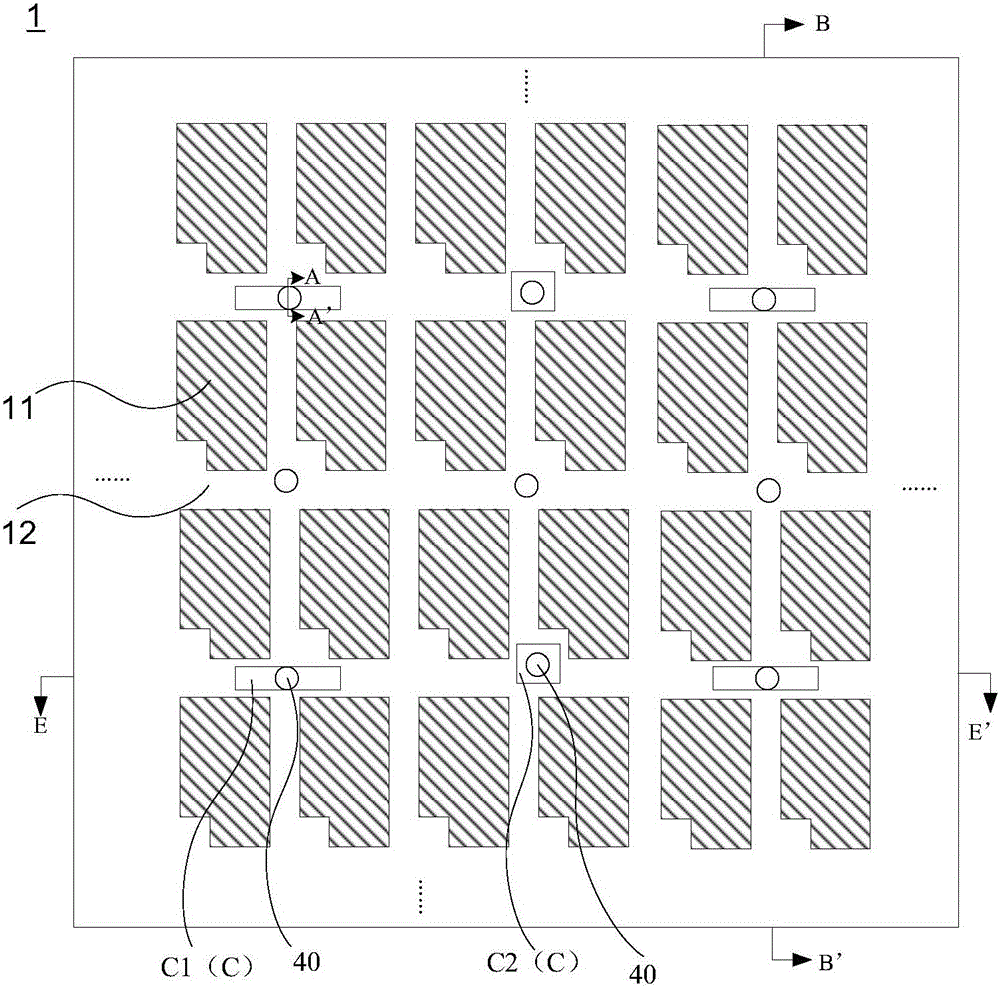

[0038] The embodiment of the present invention is mainly aimed at the problem that the top of the columnar spacer (PS) in the liquid crystal display panel is prone to position displacement, which may cause light leakage or blue spot phenomenon. Therefore, the liquid crystal display panel of the embodiment of the present invention should include PS . Generally speaking, a liquid crystal display panel is formed by two substrates paired with a cell, and the PS is located between the two substrates to ensure a certain cell thickness between the two substrates. PS has a bottom end and a top end; since the PS is set on one of the substrates, one end of the PS set on the substrate is called the bottom end of the PS, the bottom end of the PS is fixed, and the other end of the PS is called the top end of the PS. The top of the PS will abut against the upper surface of another substrate, and the top of the PS may be displaced.

[0039] Next, the structure of the liquid crystal display ...

Embodiment 2

[0072] An embodiment of the present invention provides a display device, which may include any liquid crystal display panel 1 provided in Embodiment 1, so the display device is also called a liquid crystal display device. Exemplarily, the liquid crystal display device may include other components such as a backlight module and a frame in addition to the liquid crystal display panel 1 .

[0073] The liquid crystal display device may be a product or component with any display function, such as a liquid crystal display, a liquid crystal TV, a digital camera, a mobile phone, and a tablet computer. In the display device provided by the embodiment of the present invention, by adding spacer limiting groove C, the top of the columnar spacer can be placed in the groove, thereby restricting the movement of the top of the spacer; The limit groove C is located in the pixel boundary area 12, thereby reducing the positional displacement of the top of the columnar spacer to the pixel area; i...

Embodiment 3

[0075] An embodiment of the present invention provides a method for manufacturing a liquid crystal display panel. The liquid crystal display panel includes a pixel area and a pixel defining area surrounding the pixel area. refer to Figure 10 , the manufacturing method includes the following steps:

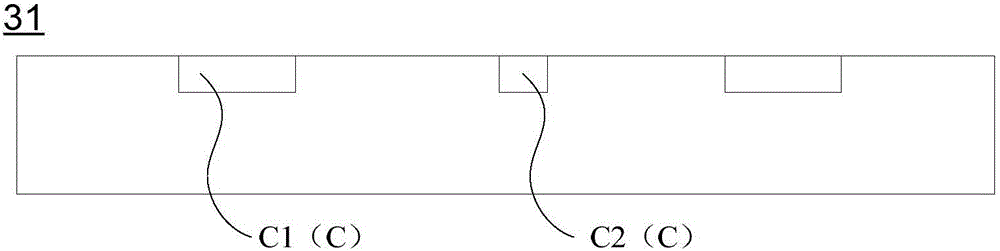

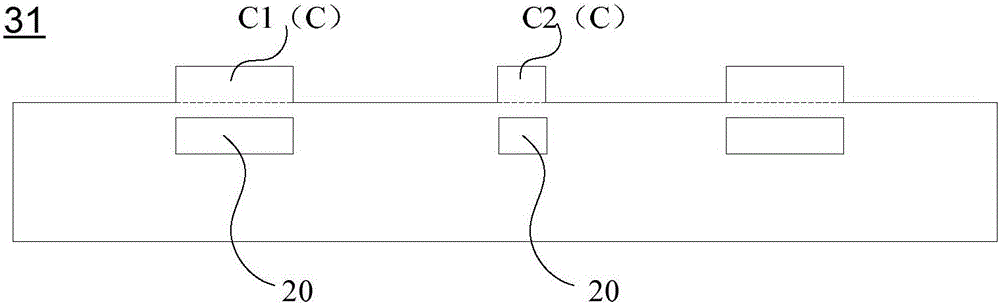

[0076] S101 , forming a thin film on the first substrate, and patterning the part of the thin film located in the pixel defining region to form a groove, so as to obtain the first substrate 31 with a spacer limiting groove C on the upper surface.

[0077] The material of the first substrate can be glass or flexible material.

[0078] Wherein, those skilled in the art can select the material for making the thin film according to actual needs, for example, metals, such as molybdenum, copper, silver, etc. can be selected. Taking the first substrate 31 as an array substrate and fabricating spacer support pads with grooves on the flat layer as an example, this step can specifically b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com