Method of manufacturing liquid crystal device and liquid crystal device

一种液晶装置、制造方法的技术,应用在光学、仪器、非线性光学等方向,能够解决液晶单元难、偏振光板的光轴对位、对位及粘贴工序变多等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0079]

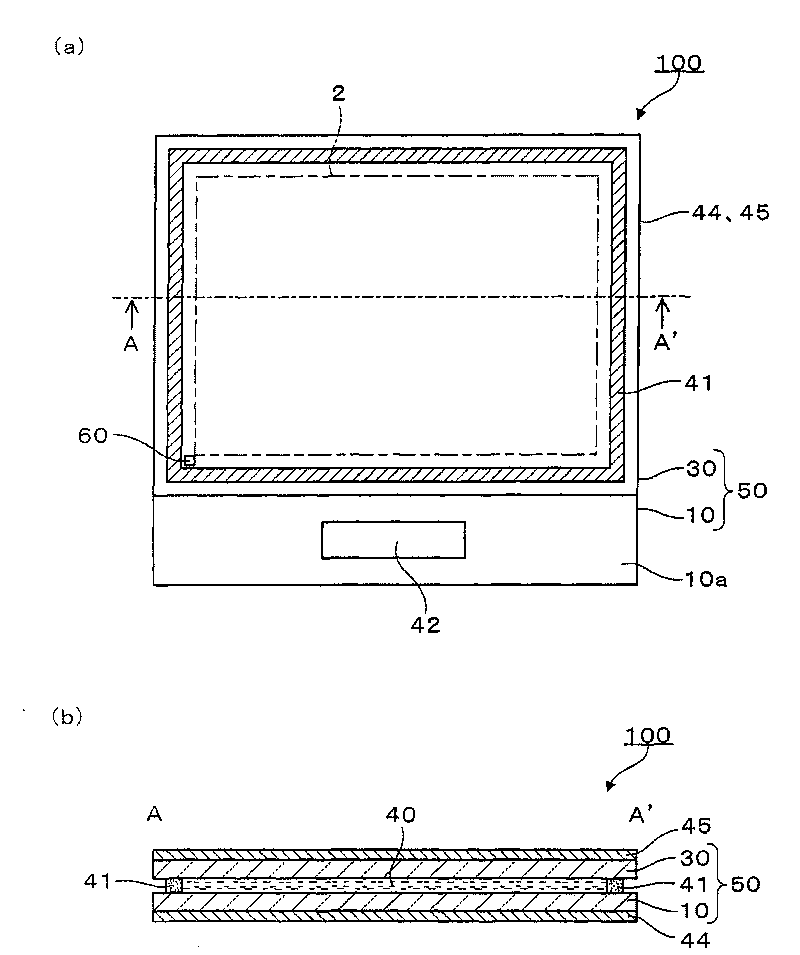

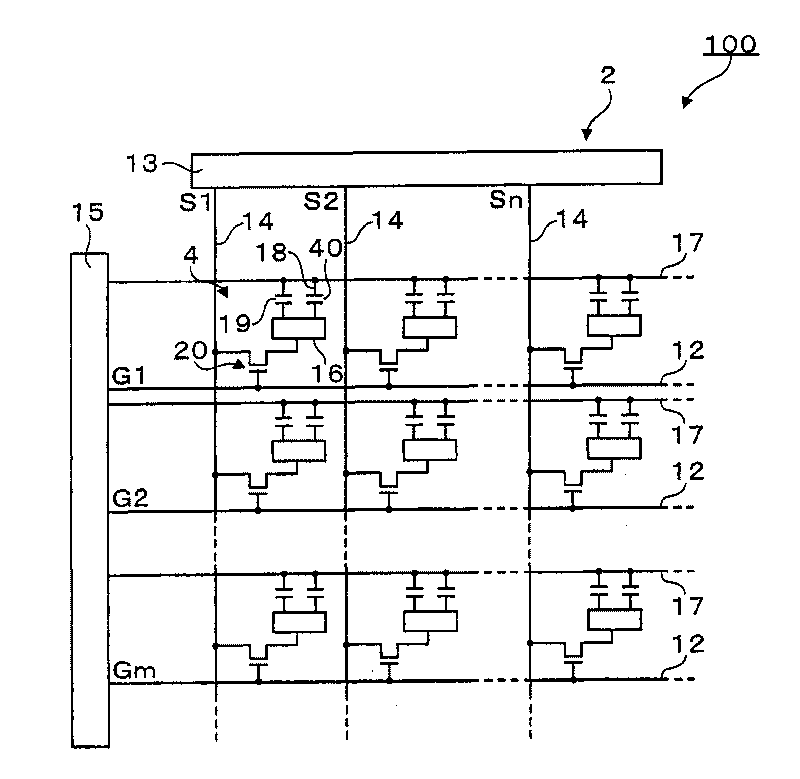

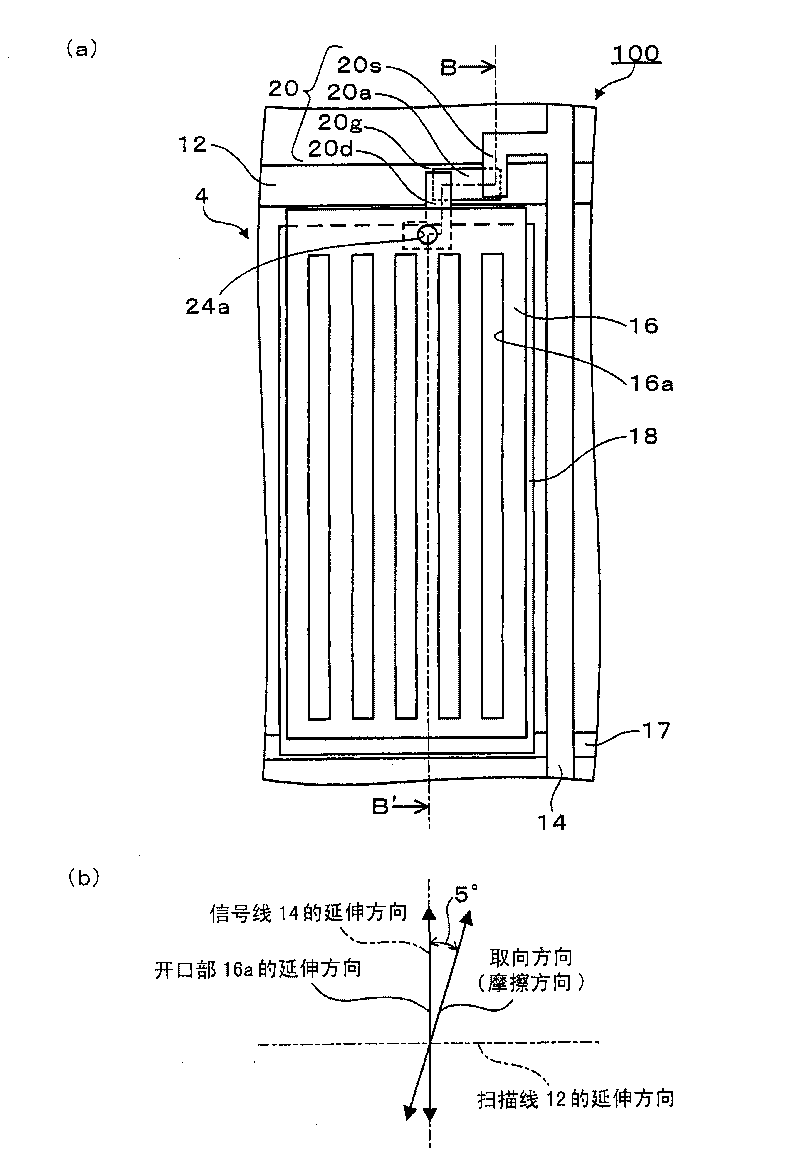

[0080] First, a liquid crystal device according to a first embodiment will be described with reference to the drawings. figure 1It is a figure showing the schematic structure of the liquid crystal device of 1st Embodiment. in particular, figure 1 (a) is a top view of a liquid crystal device, figure 1 (b) is along figure 1 A cross-sectional view of line A-A in (a). figure 2 It is an equivalent circuit diagram showing the electrical configuration of the liquid crystal device of the first embodiment. image 3 It is a figure explaining the structure of the pixel of the liquid crystal device of 1st Embodiment. in particular, image 3 (a) is a plan view showing the structure of a pixel viewed from the counter substrate side, image 3 (b) is a figure which shows the orientation direction of a liquid crystal cell. Figure 4 is along image 3 Section view of line B-B in (a). In addition, in image 3 In (a), illustration of the counter substrate is omitted.

[008...

no. 2 approach

[0149]

[0150] Next, a liquid crystal device according to a second embodiment will be described with reference to the drawings. Figure 11 It is a figure explaining the wire grid polarizer of 2nd Embodiment. In detail, Figure 11 (a) is a perspective view showing a schematic structure of a wire grid polarizer, Figure 11 (b) is a diagram showing optical design conditions.

[0151] The liquid crystal device of the second embodiment is different from the liquid crystal device of the first embodiment in that the directions of the transmission axis and the reflection axis of the wire grid polarizer are different, and the other structures are the same. The same reference numerals are assigned to the same constituent elements as those of the first embodiment, and description thereof will be omitted.

[0152] Such as Figure 11 As shown in (a), the wire grid polarizer 62 included in the liquid crystal device of the second embodiment includes a plurality of metal reflective fil...

no. 3 approach

[0163]

[0164] Next, a liquid crystal device and a manufacturing method thereof according to a third embodiment will be described with reference to the drawings. Figure 12 It is a plan view of the schematic structure of the liquid crystal device of 3rd Embodiment.

[0165] The liquid crystal device of the third embodiment differs from the liquid crystal device of the first embodiment in that the wire grid polarizer is disposed outside the region surrounded by the sealant 41 , and the structure is the same except for that. The same reference numerals are assigned to the same constituent elements as those of the first embodiment, and description thereof will be omitted.

[0166] exist Figure 12 In the example of the liquid crystal device 110 shown in (a), the wire grid polarizer 60 is disposed outside the area surrounded by the sealant 41 , that is, at a position not overlapping the liquid crystal layer 40 in plan view.

[0167] According to such a structure, even when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com