Deep hole drilling machine

A deep hole drilling machine, bed technology, applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc. problems such as poor stability, compact structure, stable clamping and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

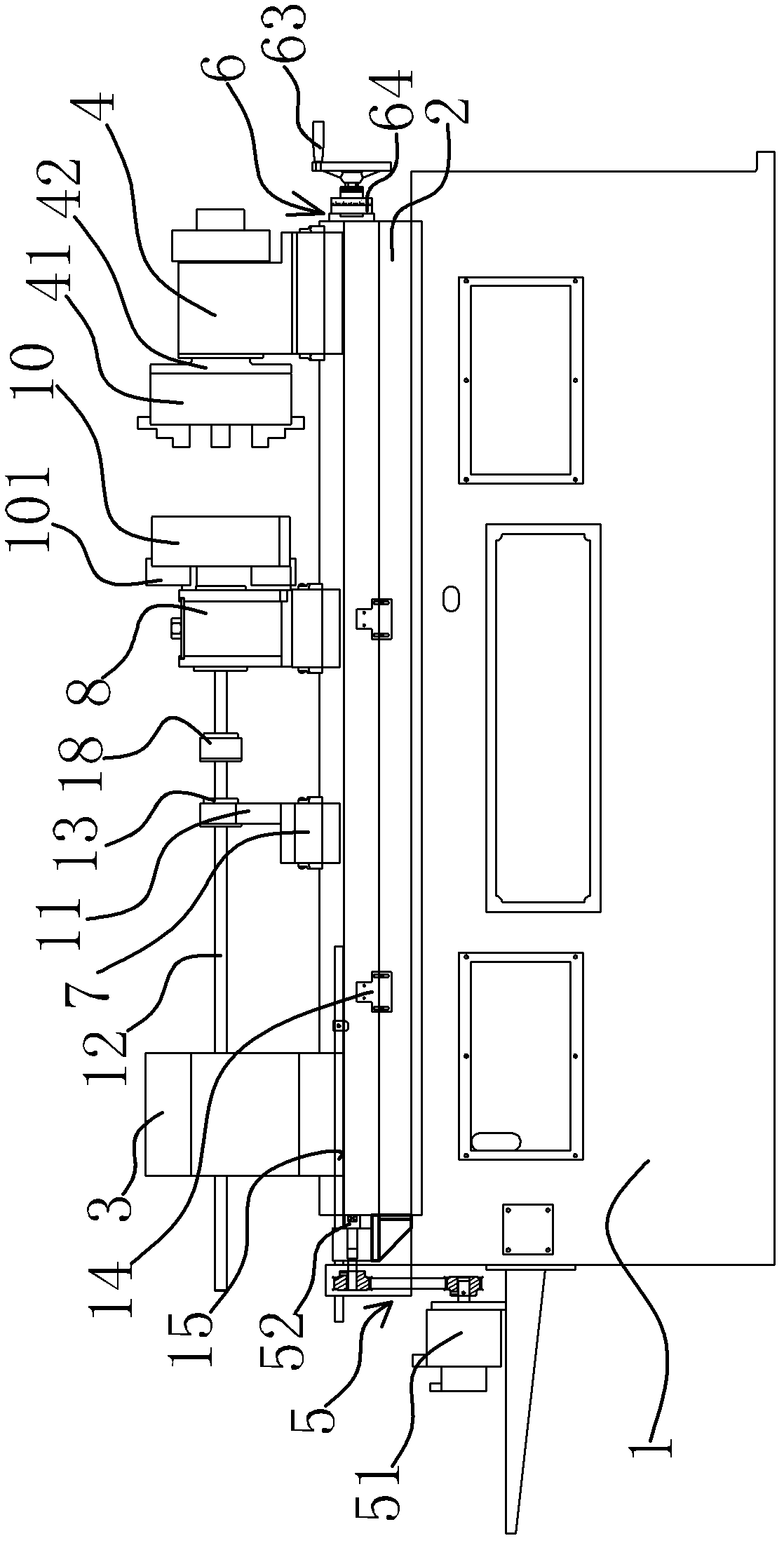

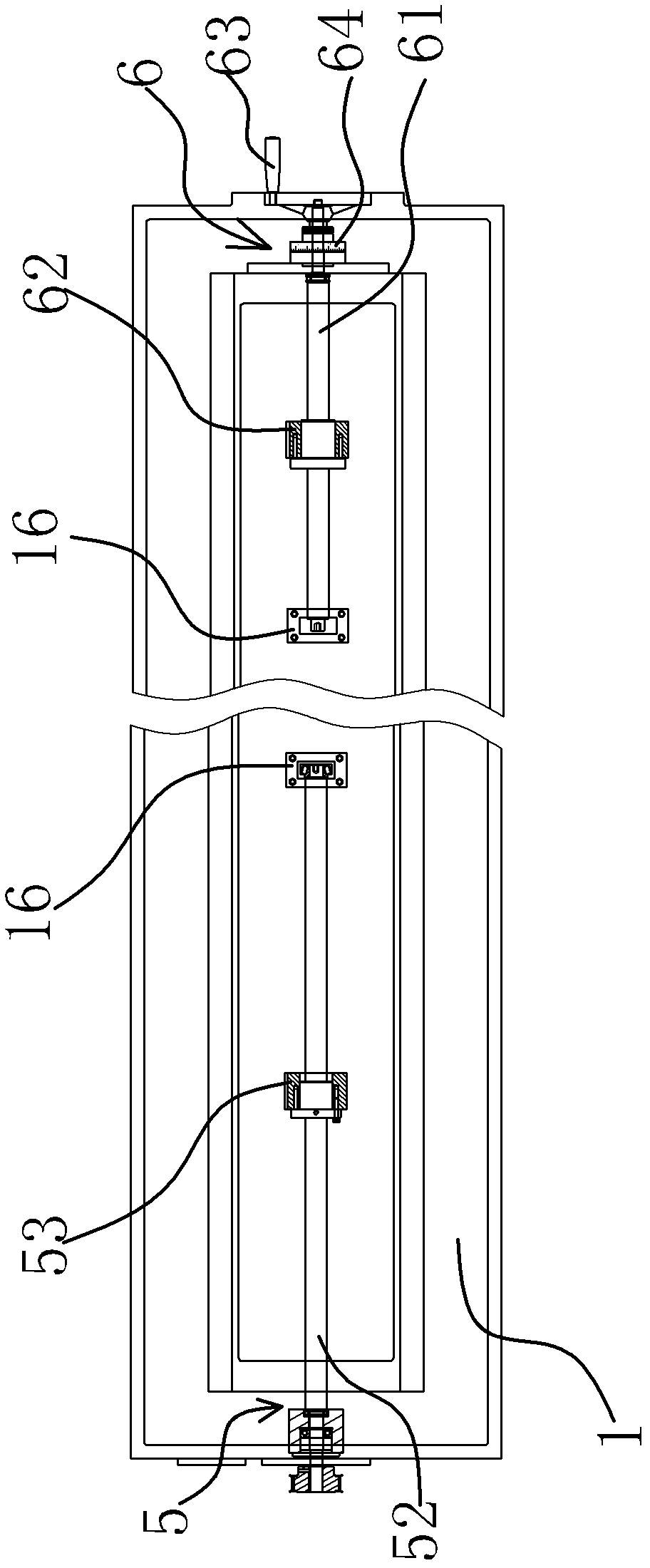

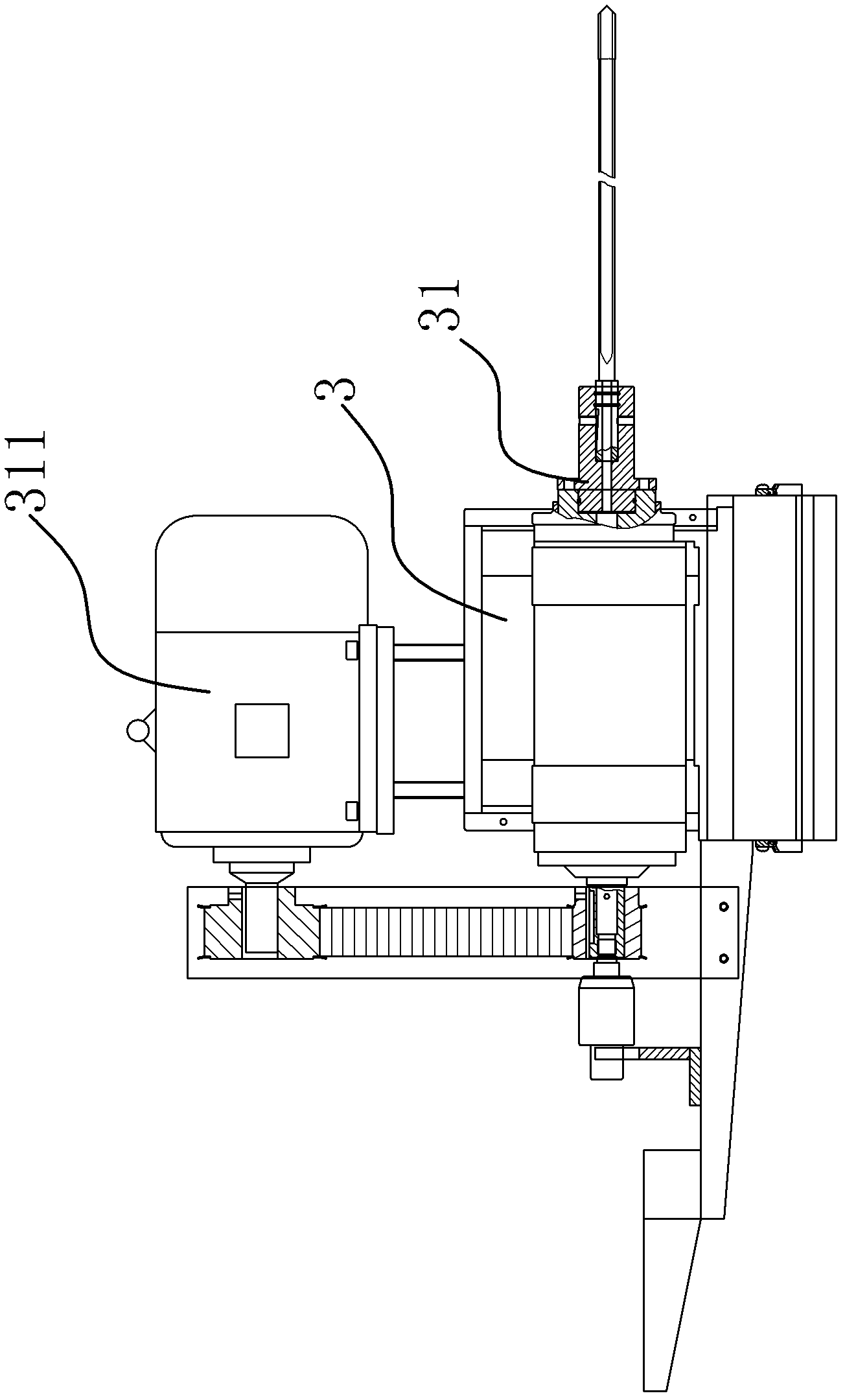

[0032] This deep hole drilling machine is used for deep hole processing of workpieces, including bed 1, slide rail 2, power head 3 and tailstock 4. Such as figure 1 , figure 2 with image 3 As shown, the tailstock 4 and the power head 3 are arranged on the slide rail 2, the power head 3 is provided with a feed spindle 31, the tailstock 4 is provided with a rotating spindle 42, and a driving mechanism is provided between the power head 3 and the bed 1 15. A driving mechanism 26 is provided between the tailstock 4 and the bed 1.

[0033] Such as figure 1 , figure 2 with image 3 As shown, in the present embodiment, the driving mechanism one 5 includes a driving motor two 51, a screw mandrel one 52 and a screw nut one 53, the driving motor two 51 is fixed on the motor bracket of the bed 1, and the screw mandrel one 52 passes through the positioning seat 16 Axial positioning with bed 1. Driving motor two 51 is connected with screw mandrel one 52 by pulley transmission mec...

Embodiment 2

[0042] The technical solution of this embodiment is basically the same as the technical solution of Embodiment 1, the difference is that in this embodiment, the driving mechanism 5 includes an oil cylinder and an oil supply mechanism, the cylinder body of the oil cylinder is fixed on the power head 3, and the cylinder body of the oil cylinder The end of the piston rod is fixed on the bed 1, and the oil supply mechanism communicates with the oil chamber of the oil cylinder. The oil cylinder is used to drive the power head 3 to feed, and the feed movement is stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com