Control circuit of construction machine

A control circuit and construction machinery technology, applied in mechanical equipment, construction, servo meter circuits, etc., can solve problems such as bad user claims, inefficiency, and deterioration of operability, so as to improve level leveling workability, suppress labor and costs, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

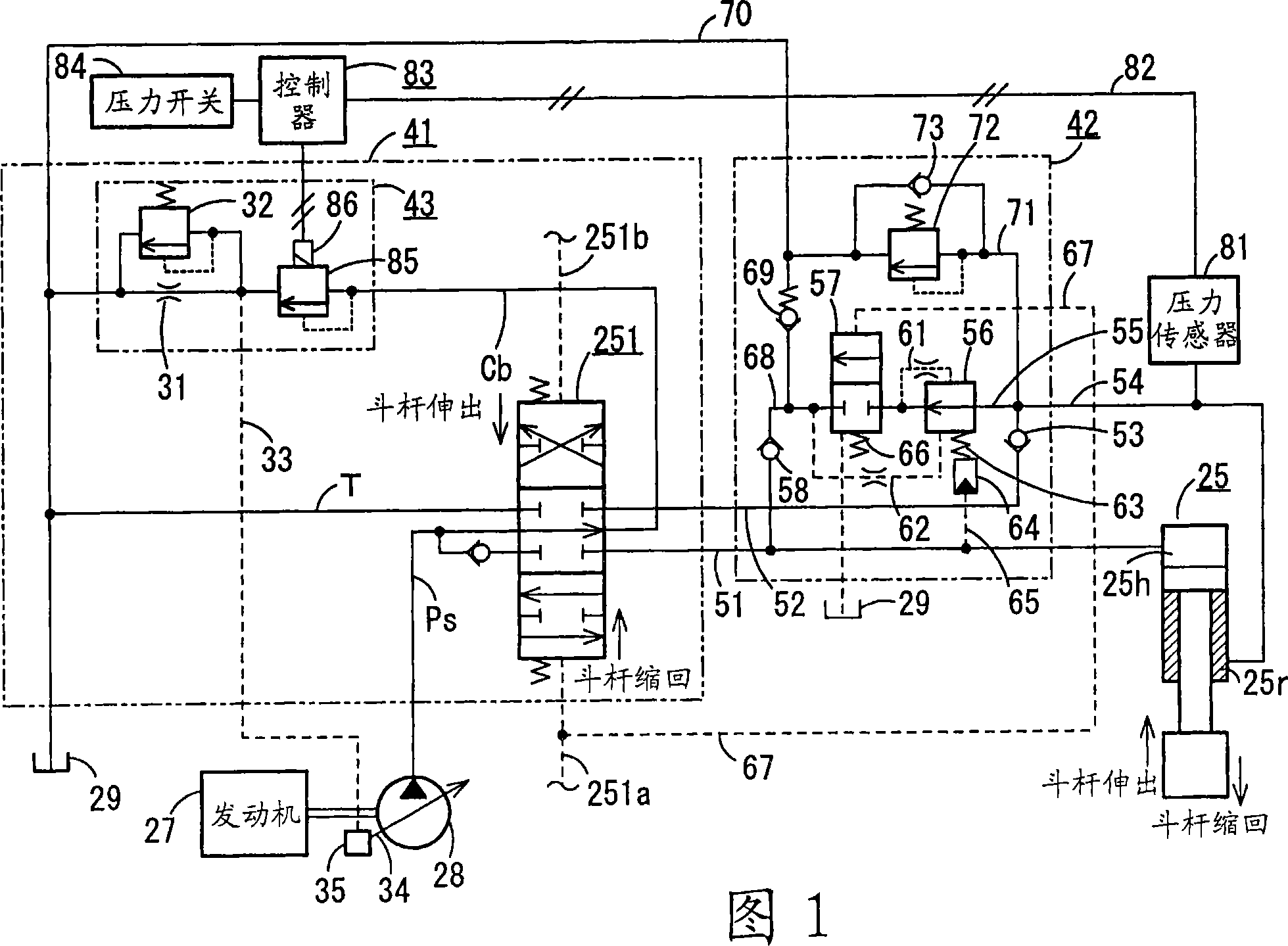

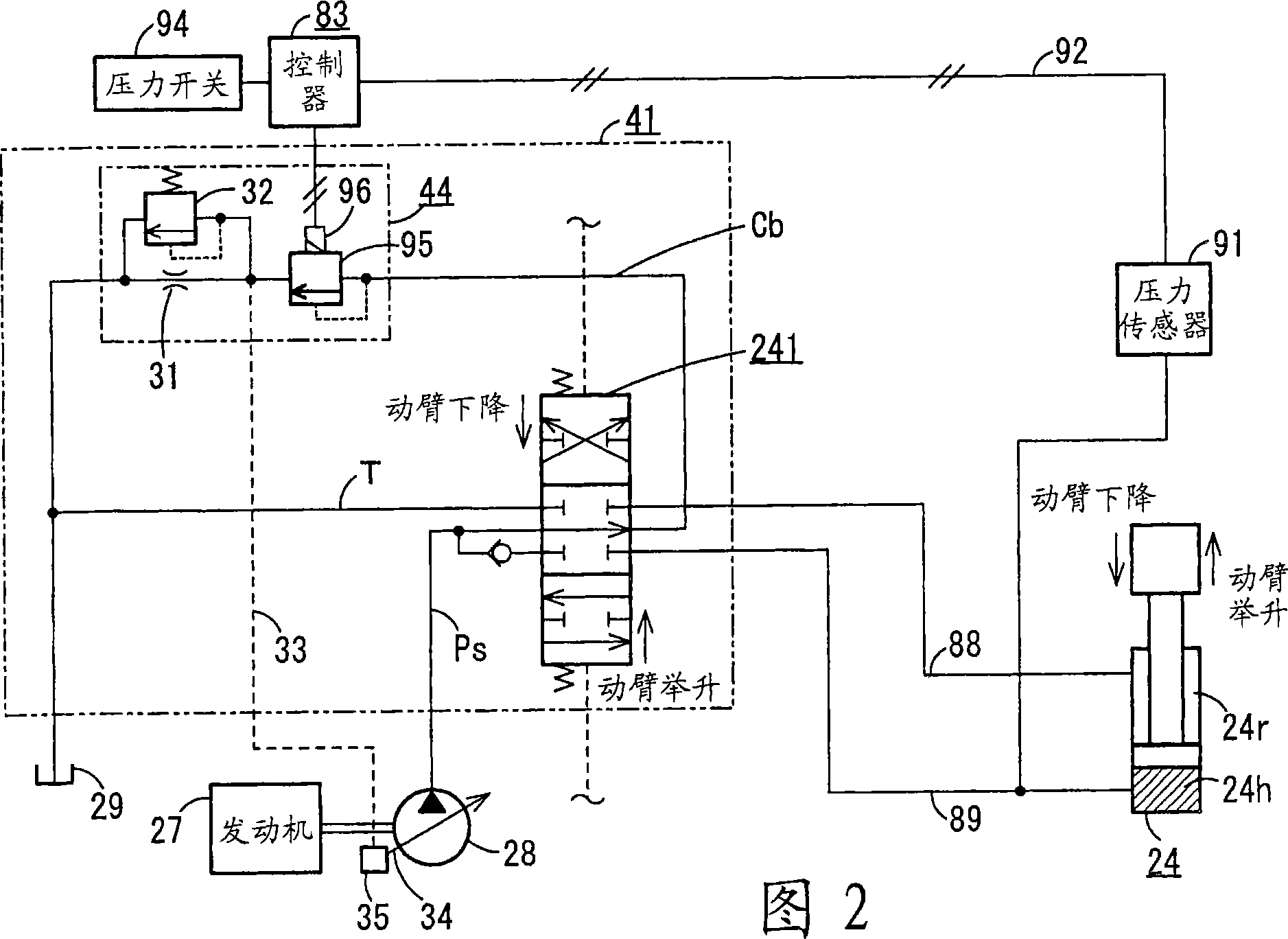

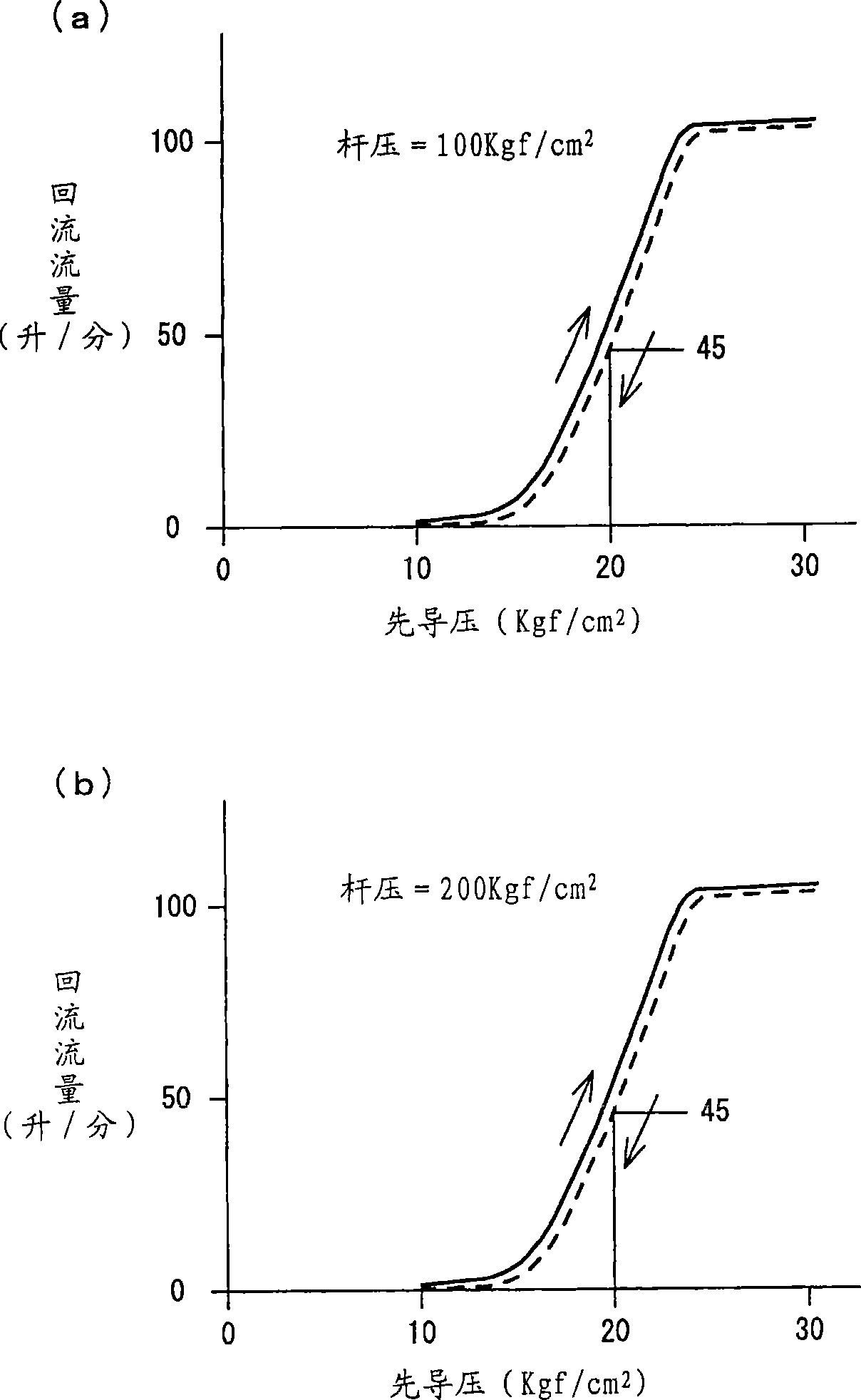

[0046] Hereinafter, the present invention will be described with reference to one embodiment shown in FIGS. 1 to 4 . in addition, Figure 5 The illustrated circuits are basic circuits that serve as the premise of the present invention, and descriptions thereof may be omitted by attaching the same symbols to the same parts, and the circuits of the traveling system, swing system, and bucket system are omitted because they are the same.

[0047] Figures 1 and 2 show the Figure 5 The load pressure compensation system in the middle opening system of the two pumps shown here, while taking advantage of the characteristics of the current middle opening system, partially performs load pressure compensation to improve the leveling performance and production in the use of large and heavy buckets performance, and the lifting operability when lifting materials.

[0048] In Fig. 1 and Fig. 2, 41 is a control valve, which is equipped with Figure 5 Spools of various operating valves 111 , 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com