table cutting machine

A desktop cutting machine, cutting machine technology, applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., can solve the problems of reducing the operating efficiency of the desktop cutting machine, sliding rod obstruction, discomfort, etc., to improve operating efficiency, Effect of ensuring uniformity and reducing rear installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

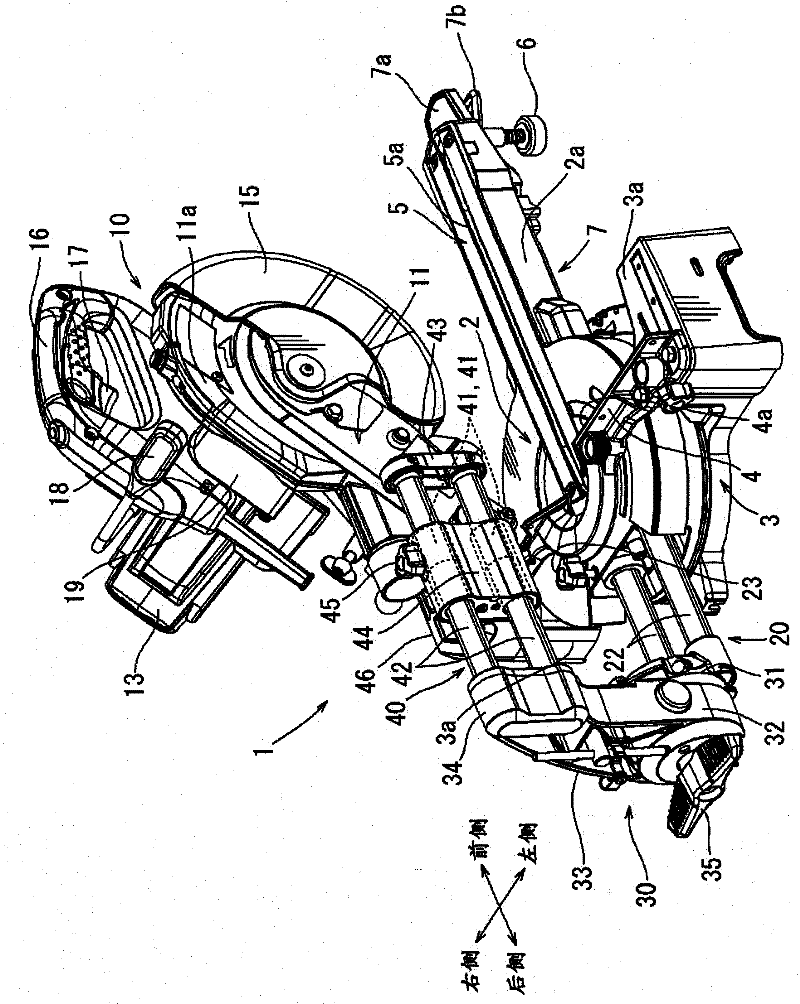

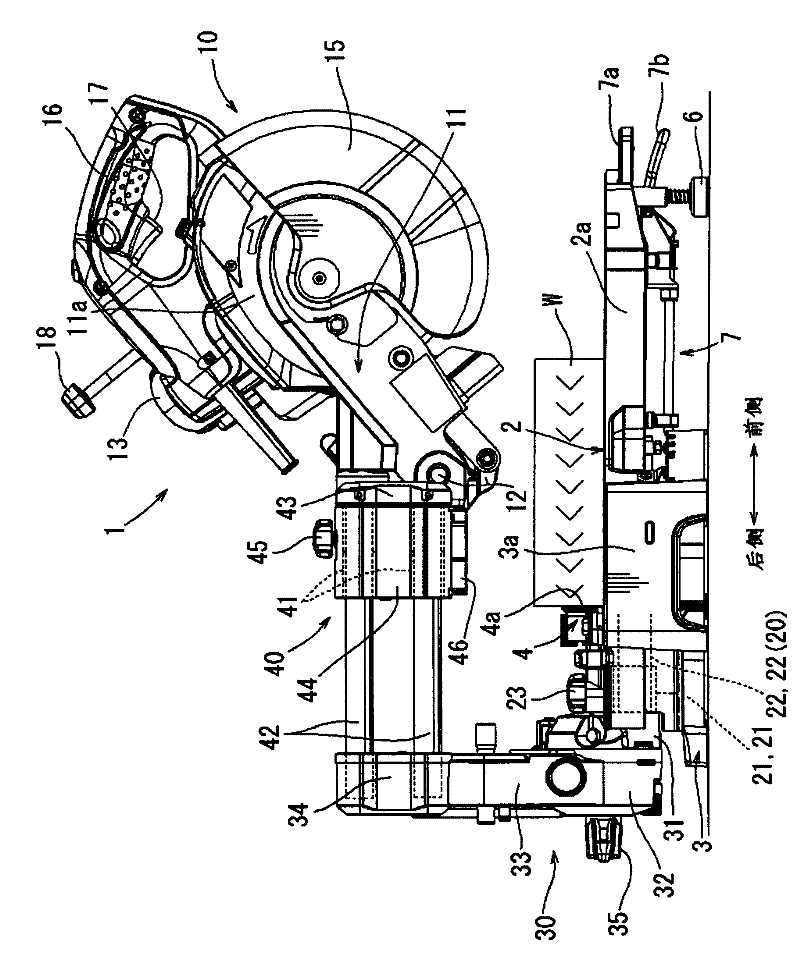

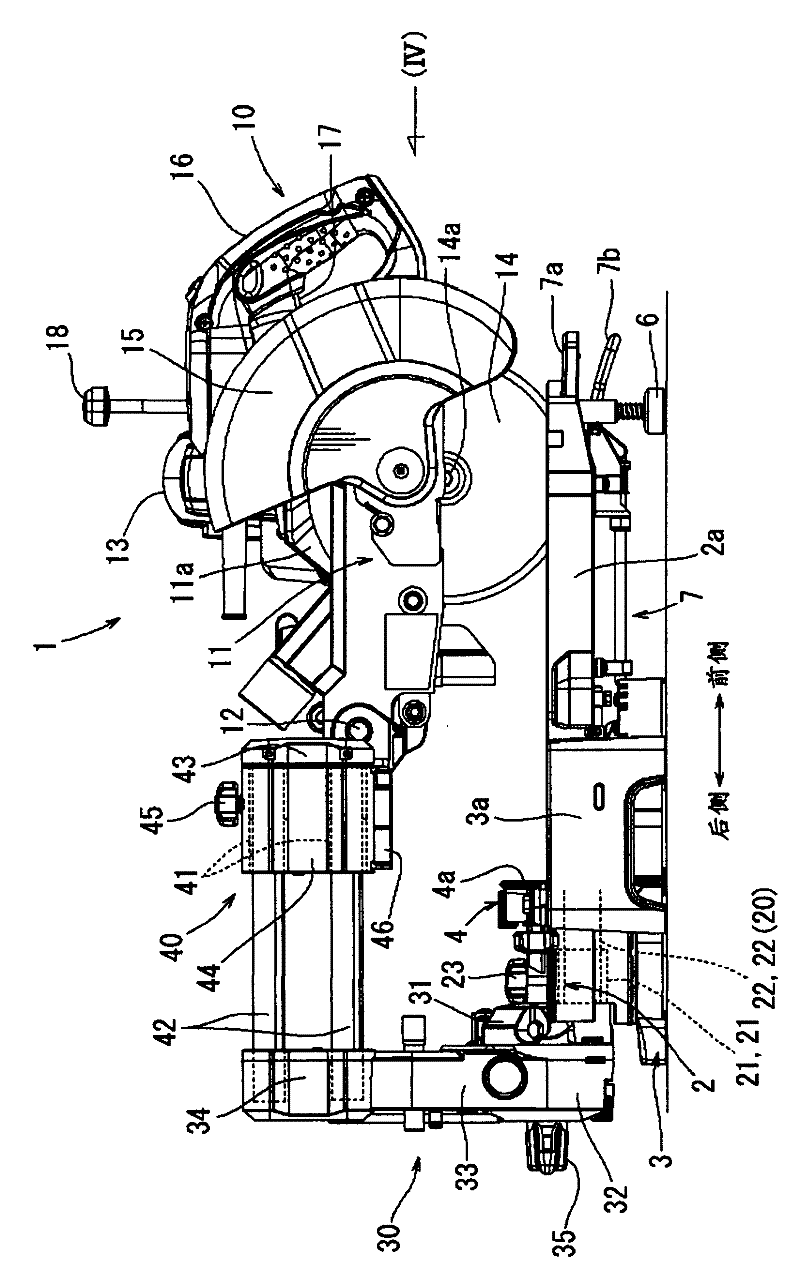

[0026] The following is based on Figure 1 to Figure 8 Embodiments of the present invention will be described. figure 1 It is a figure which shows the whole table cutting machine 1 in this embodiment. figure 1 The above-mentioned desktop cutting machine 1 shown has: a workbench 2, which is circular and used to place the material W to be cut; a base 3, on which the workbench 2 is supported and rotatable; a cutting machine body 10, which is located on Above workbench 2. And it can be flipped up and down.

[0027] Two fixed table parts 3 a are provided on both left and right sides of the table 2 . The two fixed table parts 3 a are provided on the left and right sides of the base 3 and are integrally formed with the base 3 . The table 2 is supported on the upper surface of the base 3 between the two fixed table parts 3 a. Between the two fixed table parts 3a, the positioning fence 4 for positioning the to-be-cut material is straddled and installed. The positioning baffle 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com