Mold multiple heating and cooling system

A cooling system and metal mold technology, applied in metal processing equipment, presses, forming tools, etc., can solve problems such as non-corresponding forming, and achieve the effect of saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

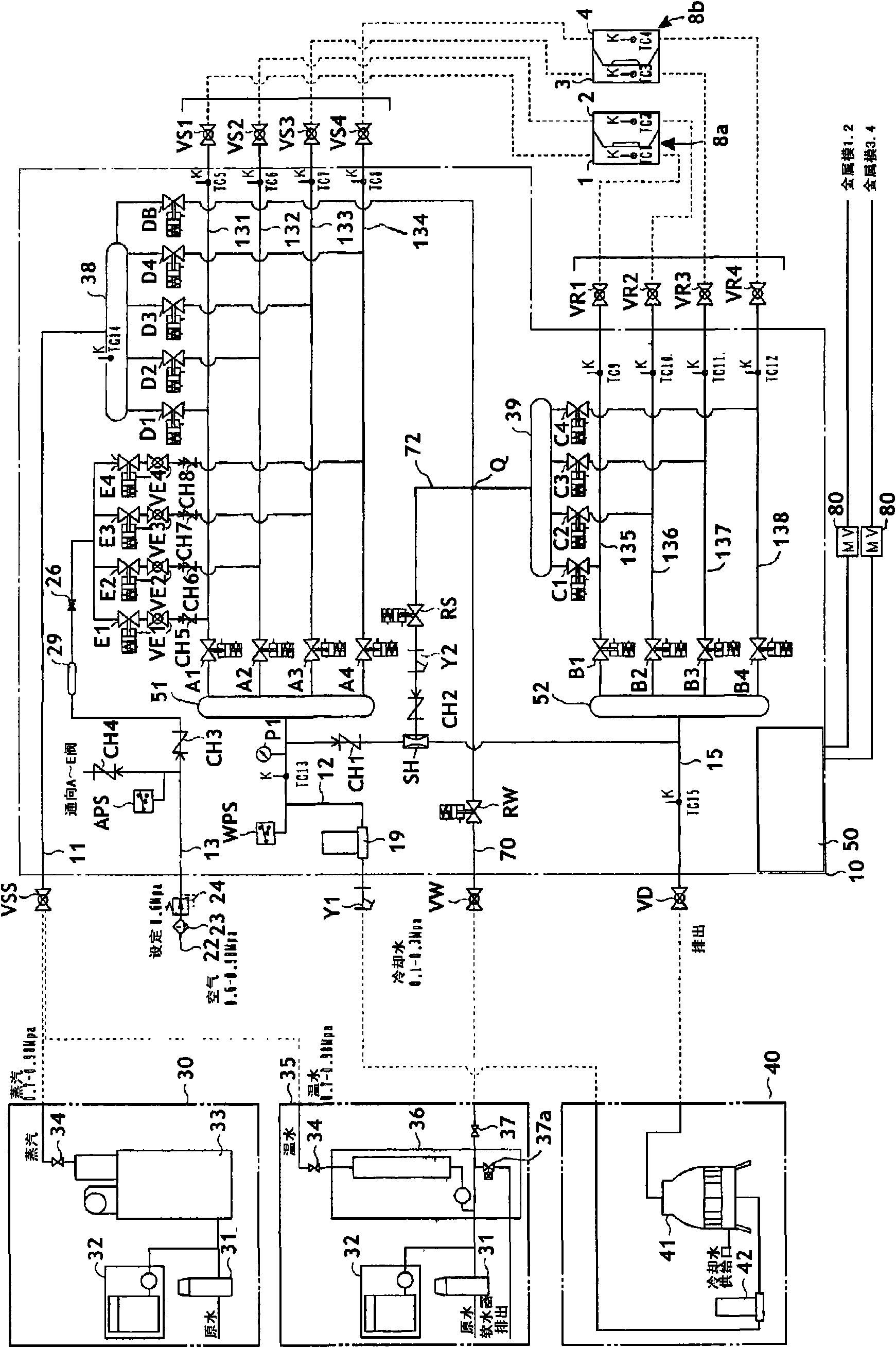

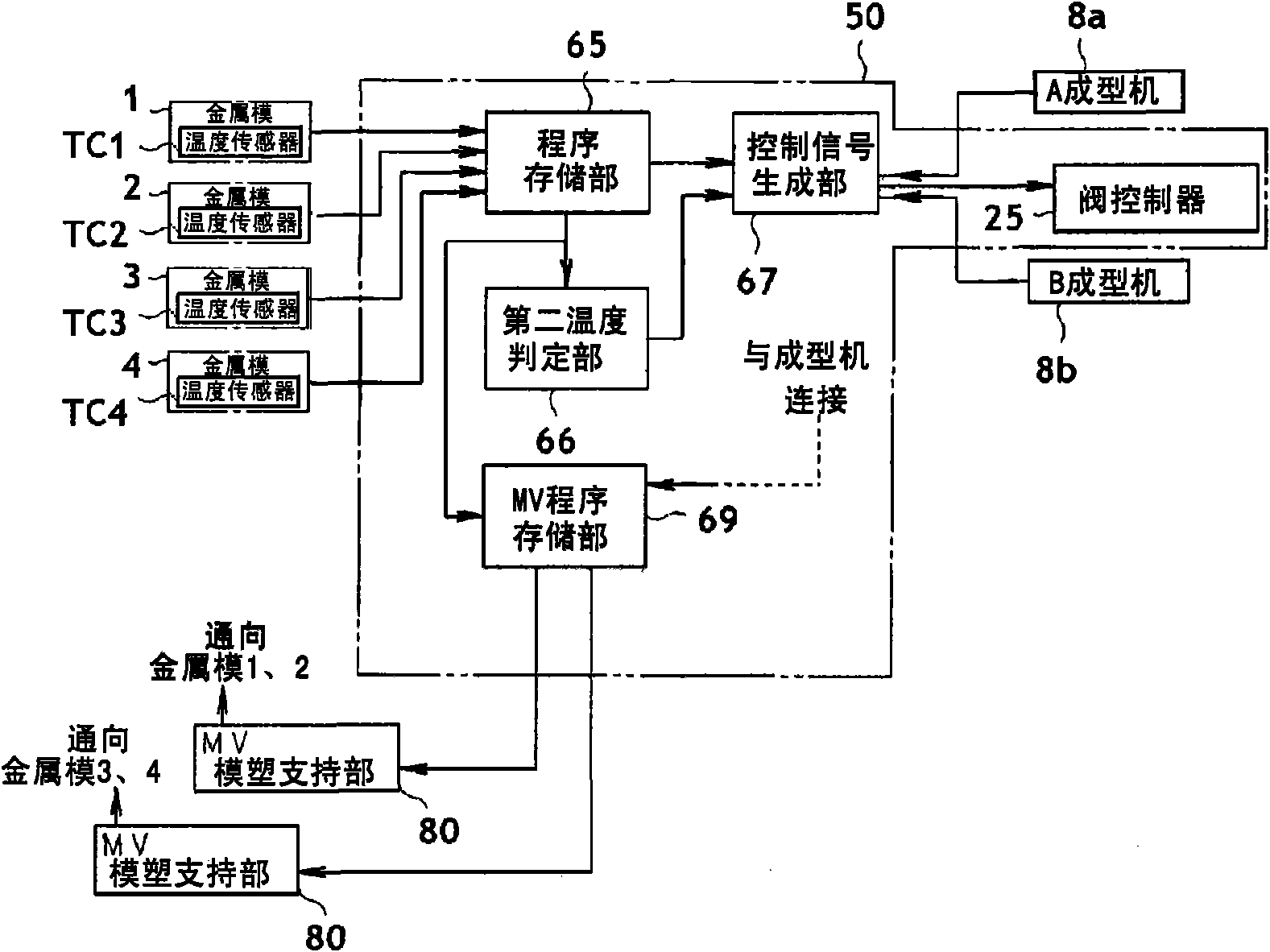

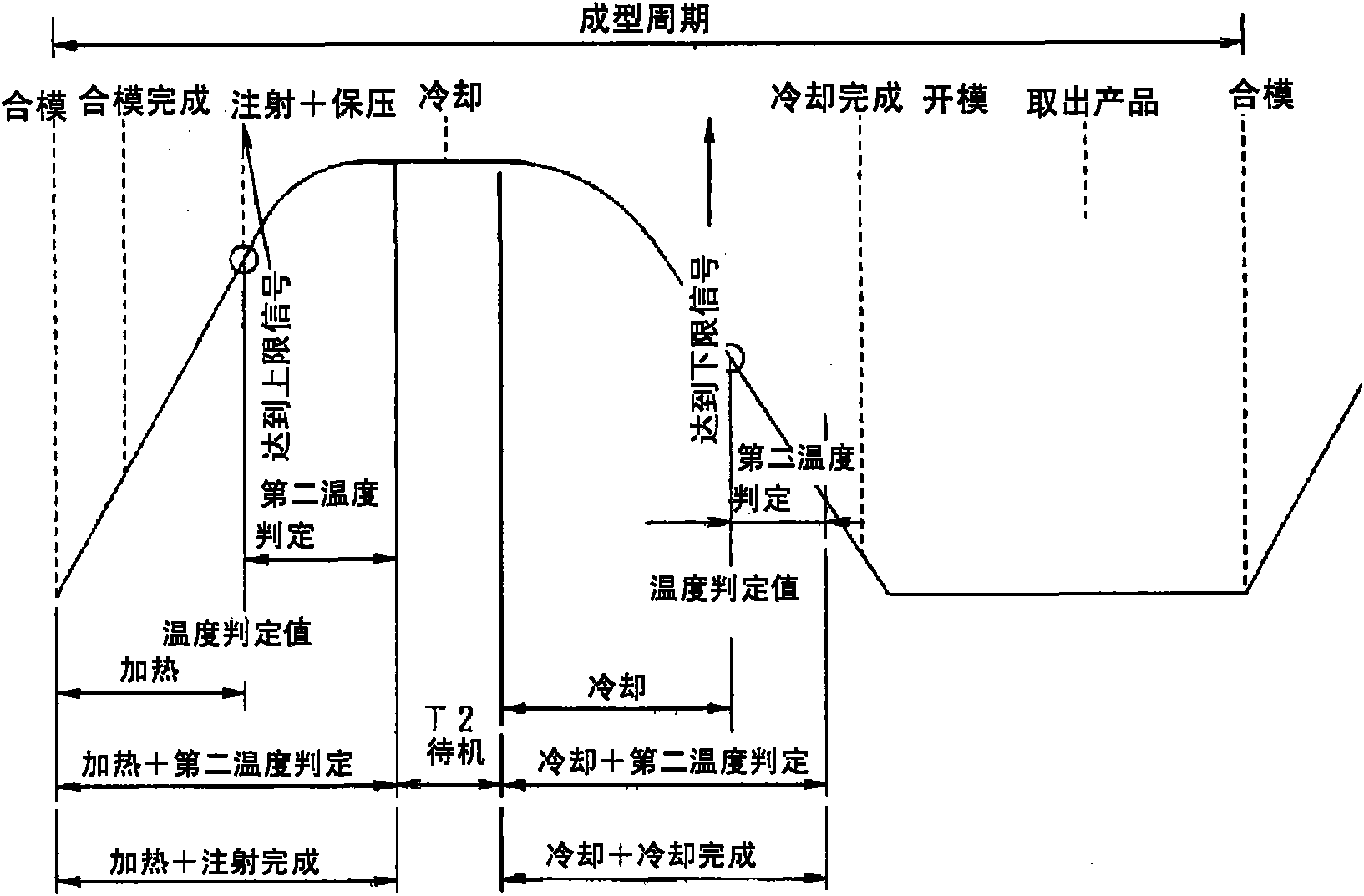

[0031] Such as figure 1 As shown, the heating and cooling system of the metal mold involved in the present embodiment 1 includes: the metal mold 1 and the metal mold 2 of the A molding machine 8a and the metal mold 3 and the metal mold of the B molding machine 8b for molding raw materials such as molding resins. The mold 4 is switched to supply steam or warm water as the heating medium, and the temperature adjustment device 10 as the cooling water of the cooling medium; the steam heating unit 30 that sends steam to the temperature adjustment device 10; the warm water that sends warm water to the temperature adjustment device 10 The heating unit 35; the cooling unit 40 that circulates the cooling water; and according to the control of the temperature regulating device 10, the above-mentioned metal mold 1, metal mold 2, metal mold 3, and metal mold 4 are vacuumized, rapidly expanded, and blown, etc., And put into the above-mentioned two molding support parts 80 as in-mold cleaning...

Embodiment 2

[0105] Next, refer to Figure 7 to Figure 9 A multiple heating and cooling system for a metal mold according to Embodiment 2 of the present invention will be described.

[0106] The multiple heating and cooling system of the metal mold involved in this embodiment 2 basically has the same structure as the multiple heating and cooling system of embodiment 1, and is characterized in that Figure 7 The shown two-material molding machine 68 replaces the A molding machine 8a and the B molding machine 8b of the first embodiment.

[0107] In the above-mentioned two-material molding machine 68, as Figure 7 As shown, a movable side metal mold (first mold core) 103 connected with the above-mentioned turning disk 102 is arranged on the rear part A side of the movable platform 101 with the turning disk 102, and the movable side metal mold 103 is arranged and fixed. A side mold (first cavity) 104, a take-out gate 105, and a rear cylinder (primary side plasticizing device) 106 supported b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com