Racking platform bent arm pushing type drill rod discharging mechanical arm

A two-story platform and curved arm technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve problems such as large safety risks, and achieve the effects of high reliability, improved operation efficiency, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and example the present invention will be further described:

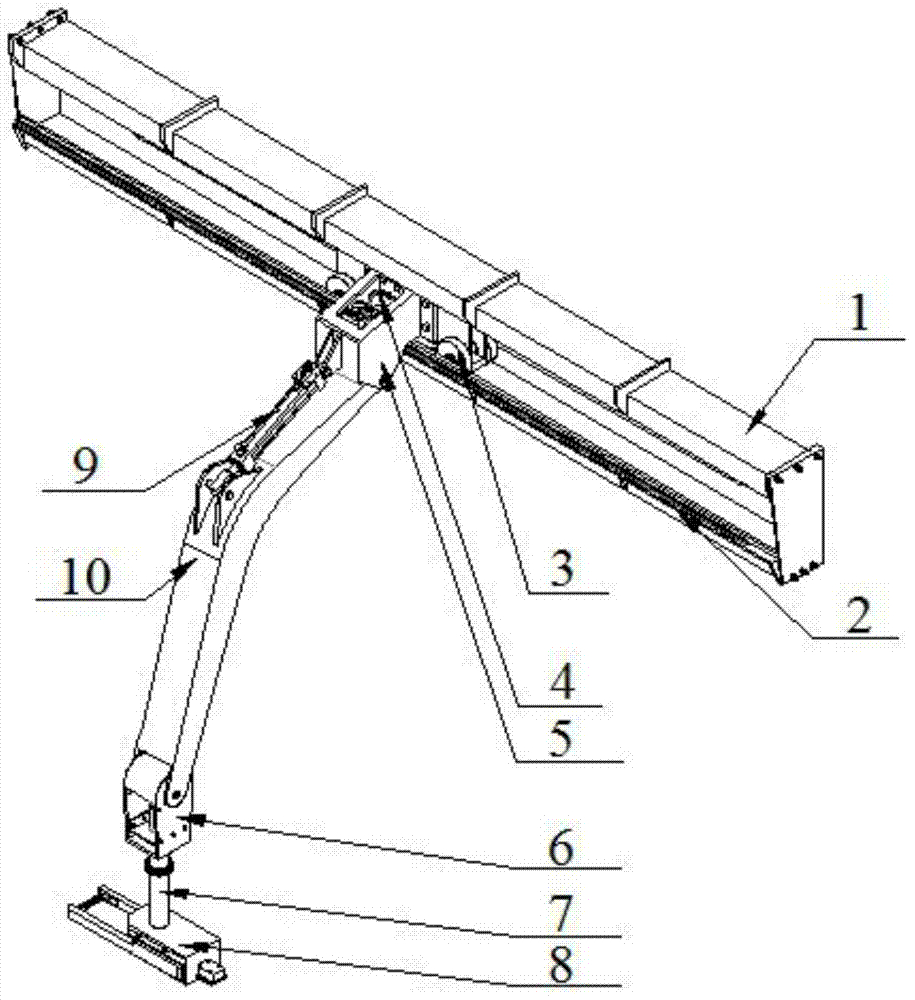

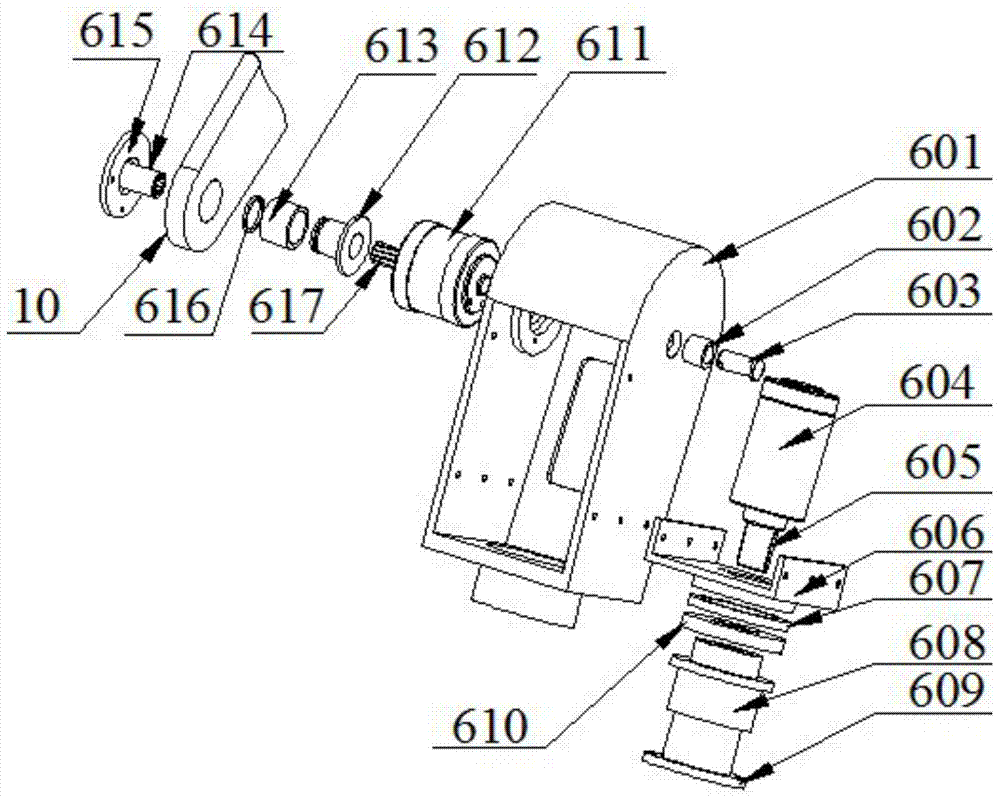

[0011] Such as figure 1 and figure 2 As shown, the curved arm push type drill pipe discharge manipulator on the second floor platform includes: track girder 1, bottom chain 2, sliding trolley 3, power unit 4, sliding base 5, small arm 6, hydraulic clamp 7, rotating rod 8, hydraulic Cylinder 9 and curved arm 10, the inner cavity of the track girder 1 is provided with a slideway, the pulley of the sliding trolley 3 is clamped on the slideway in the inner cavity of the track girder 1, and the front end of the sliding base 5 is fixed on the sliding trolley 3 by screws , the power device 4 is embedded in the inner cavity of the sliding base 5 and is fixedly connected to it, the bottom chain 2 is connected to the bottom of the track girder 1 through a sliding connection, the gear of the power device 4 is engaged with the bottom chain 2, and the rear end of the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com