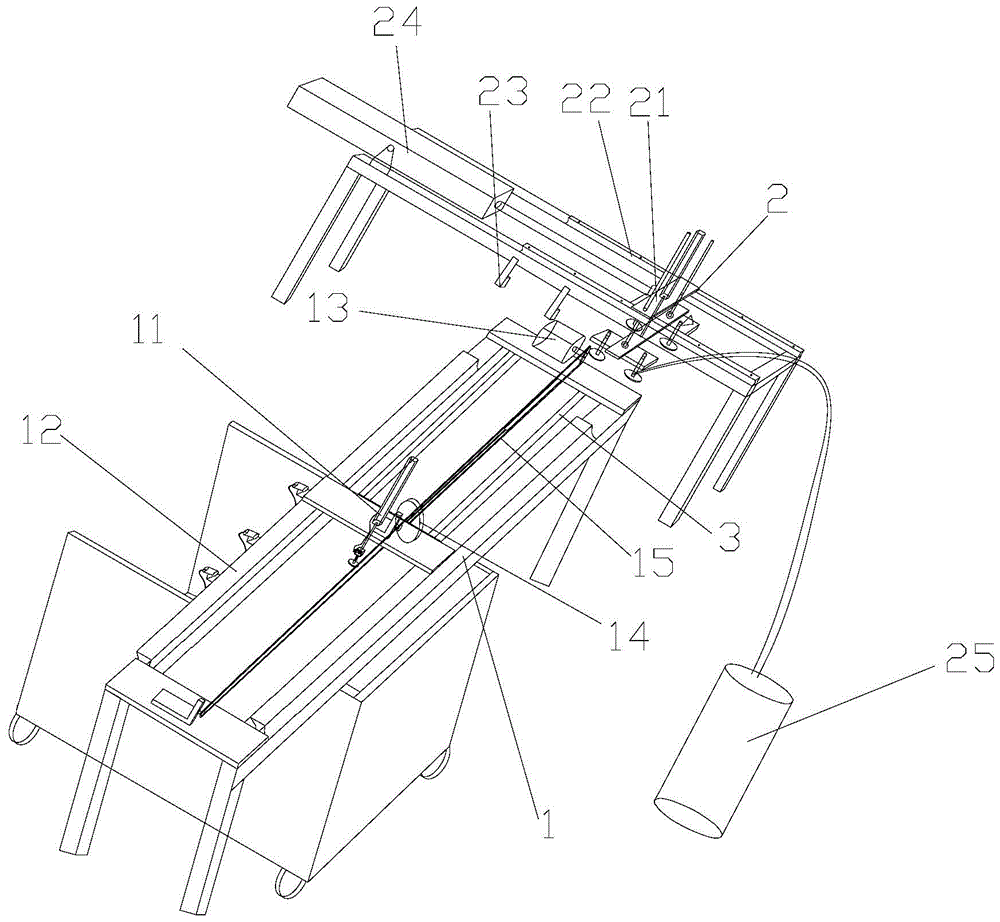

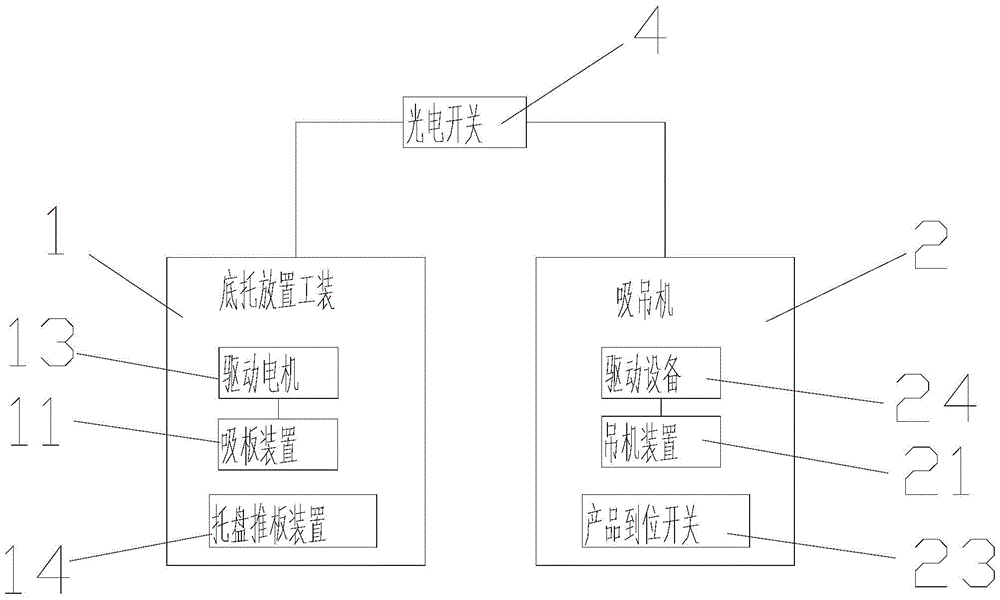

Suction transplanting device

The technology of a suction plate device and a hoist is applied to the conveyor control device, transportation and packaging, conveyors, etc., and can solve the problems of high labor intensity, low work efficiency, and the inability to realize the corresponding placement of the whole machine and the wooden bottom bracket, etc. To achieve the effect of saving labor costs, simple structure and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

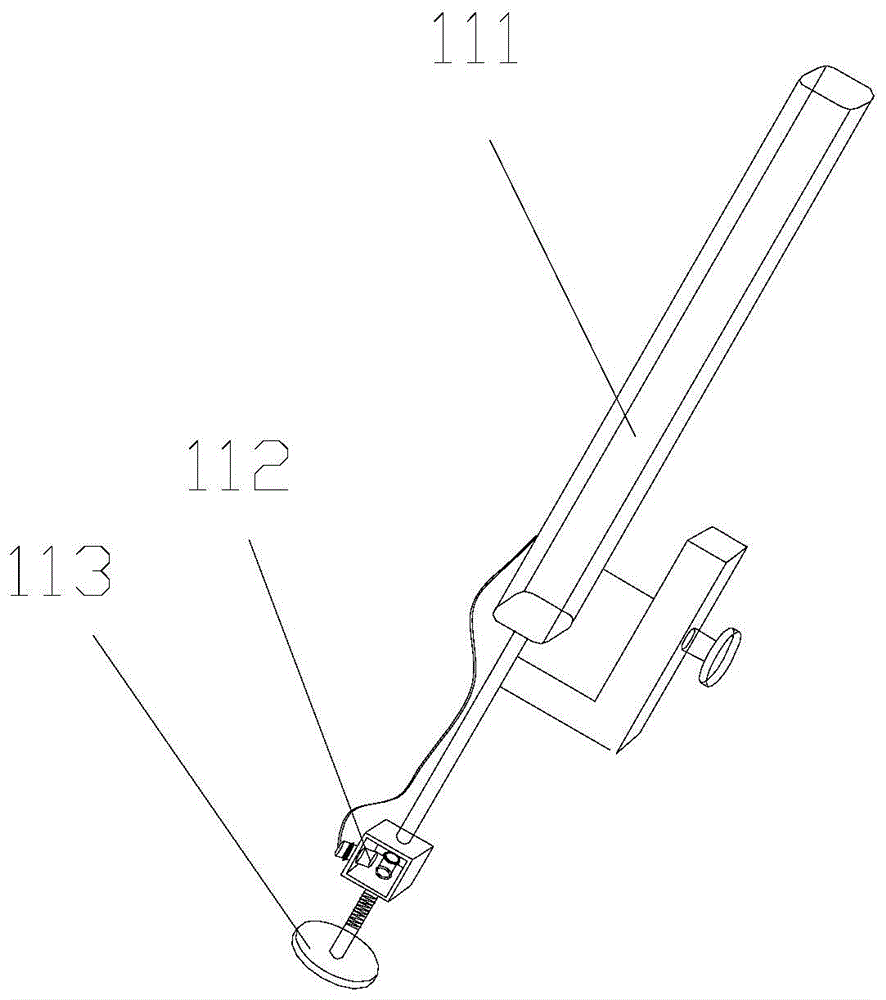

[0091] As a possible implementation, it also includes a vacuum generation controller 25;

[0092] The vacuum generating controller 25 is electrically connected with the proximity switch 214 and the tray induction switch 213 respectively, and works under the control of the proximity switch 214 and the tray induction switch 213;

[0093] The suction cup 212 is a vacuum suction cup;

[0094] The vacuum generating controller 25 is connected with the vacuum chuck for controlling the suction or disconnection of the vacuum chuck to the corresponding body.

[0095] The suction cup 212 adopts a vacuum suction cup, which can protect the surface of the body, and will not cause damage to the surface of the body due to the adsorption of the suction cup 212 to the body, thereby ensuring the quality of the product.

[0096] As a possible implementation, it also includes a pallet slide 3;

[0097] Connecting the pallet slide 3 to the first preset position and the preset position of the asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com