Automatic and uniform protective scrap placing equipment for egg packaging

An automatic technology for packaging, which is applied in the field of automatic and uniform placement of protective chips for egg packaging. It can solve the problems of uneven placement and inconvenient placement of protective chips, and achieve the effect of uniform placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

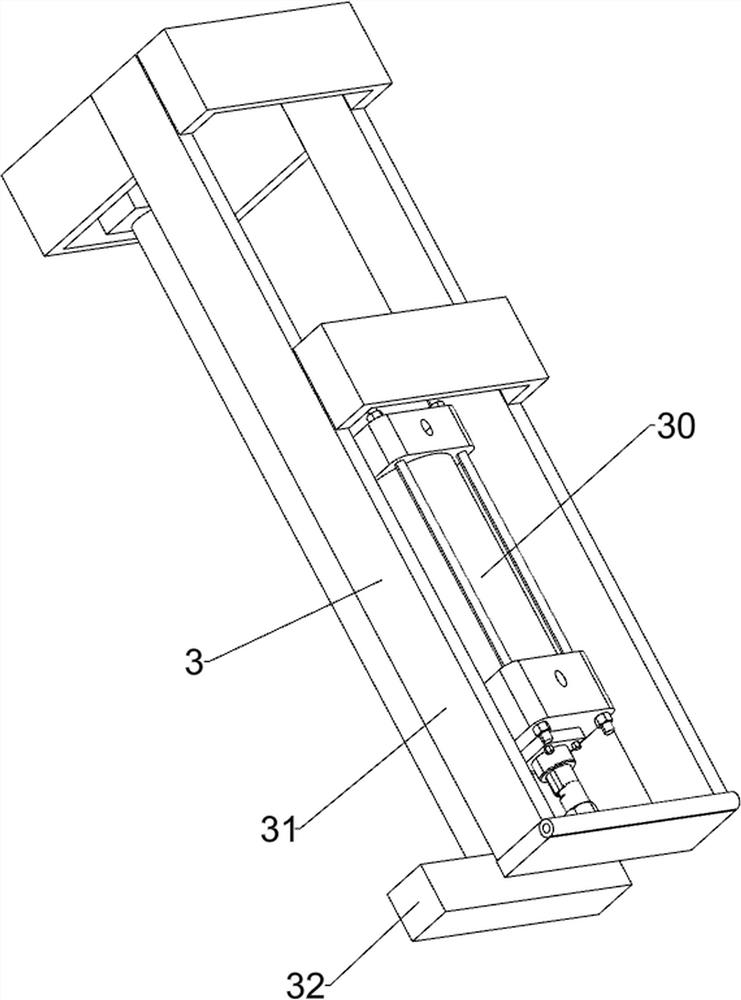

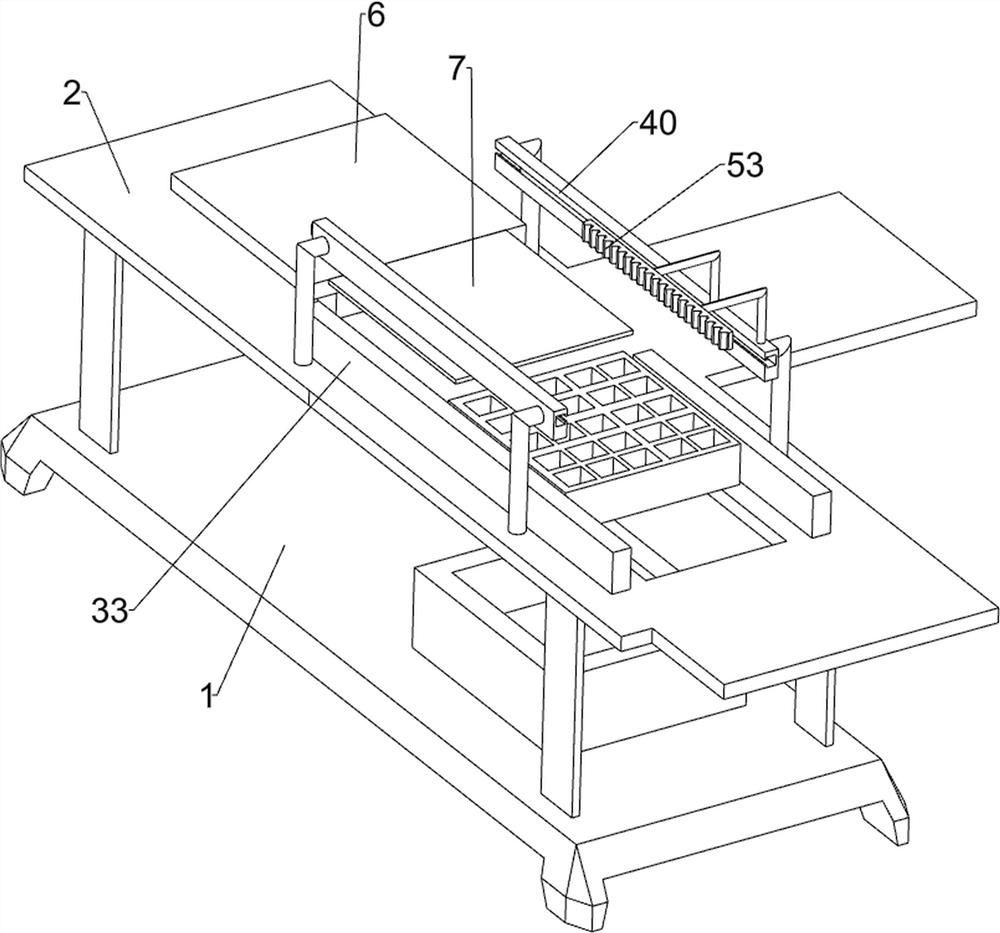

[0022] A device for automatically and evenly placing protective crumbs for egg packaging, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a bottom plate 1, a support platform 2, a propulsion mechanism 3, a moving mechanism 4, a fixed plate 6, a top material plate 7 and a collection frame 8. The top of the bottom plate 1 is fixedly connected with a support platform 2, and the support platform 2 A propulsion mechanism 3 is provided on the left side of the top, a moving mechanism 4 is provided on the right side of the top of the support platform 2, a fixed plate 6 is provided on the left side of the top of the support platform 2, a top material plate 7 is provided on the upper right side of the fixed plate 6, and a top plate 7 is provided on the right side of the support platform 2. There is a blanking opening on the side, and a collection frame 8 that falls from the packaging box is placed on the right side of the top of the bottom plate 1, and the ...

Embodiment 2

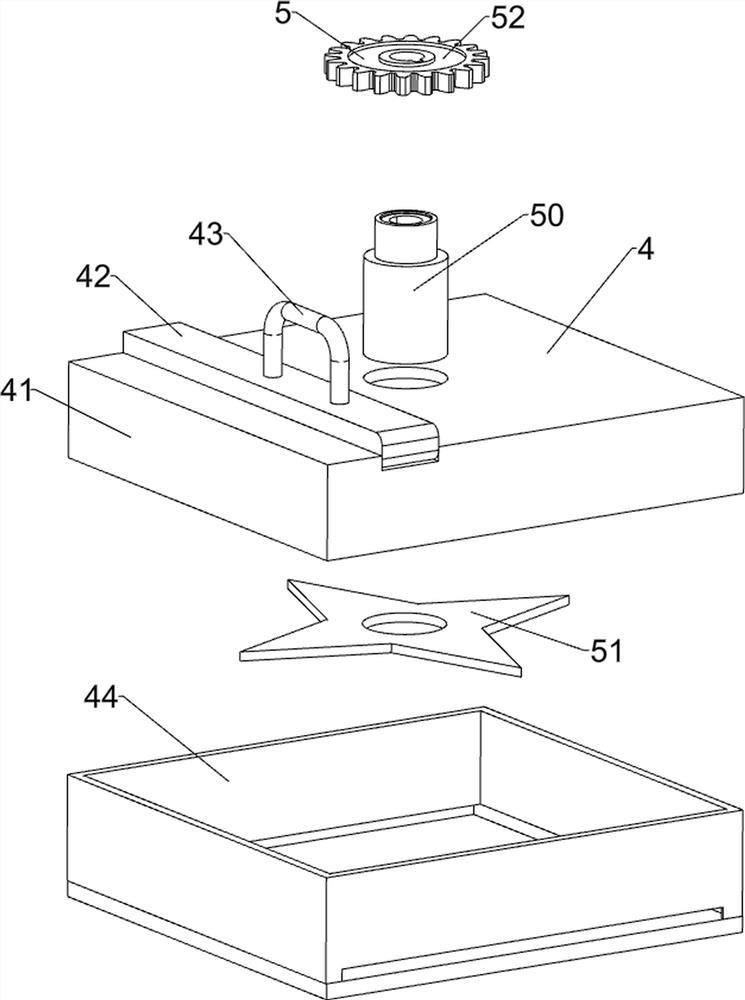

[0027] On the basis of Example 1, such as figure 1 , image 3 and Figure 4 As shown, it also includes a stirring assembly 5, the stirring assembly 5 includes a rotating rod 50, a stirring blade 51, a gear 52 and a rack 53, the upper casing 41 is rotatably provided with a rotating rod 50, and the lower end of the rotating rod 50 is provided with a stirring The blade 51 is provided with a gear 52 at the upper end of the rotating rod 50 , and the top of the rear guide rail 40 is fixedly connected with a rack 53 , and the rack 53 is meshed with the gear 52 .

[0028] It also includes a detachable connection between the stirring blade 51 and the rotating rod 50 .

[0029] During the left and right movement of the upper box body 41, the gear 52 will mesh with the rack 53, the rotation of the gear 52 will drive the rotation of the rotating rod 50, the rotation of the rotating rod 50 will drive the rotation of the stirring blade 51, and the rotation of the stirring blade 51 will ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com