High-precision automatic goods shelf system special for stereoscopic warehouse

A three-dimensional library and high-precision technology, applied in the field of shelves, can solve problems such as frequent manual operations, affecting production efficiency, and unfavorable system management, and achieve the effects of improving storage accuracy and intelligence, reasonable structure, and accurate statistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

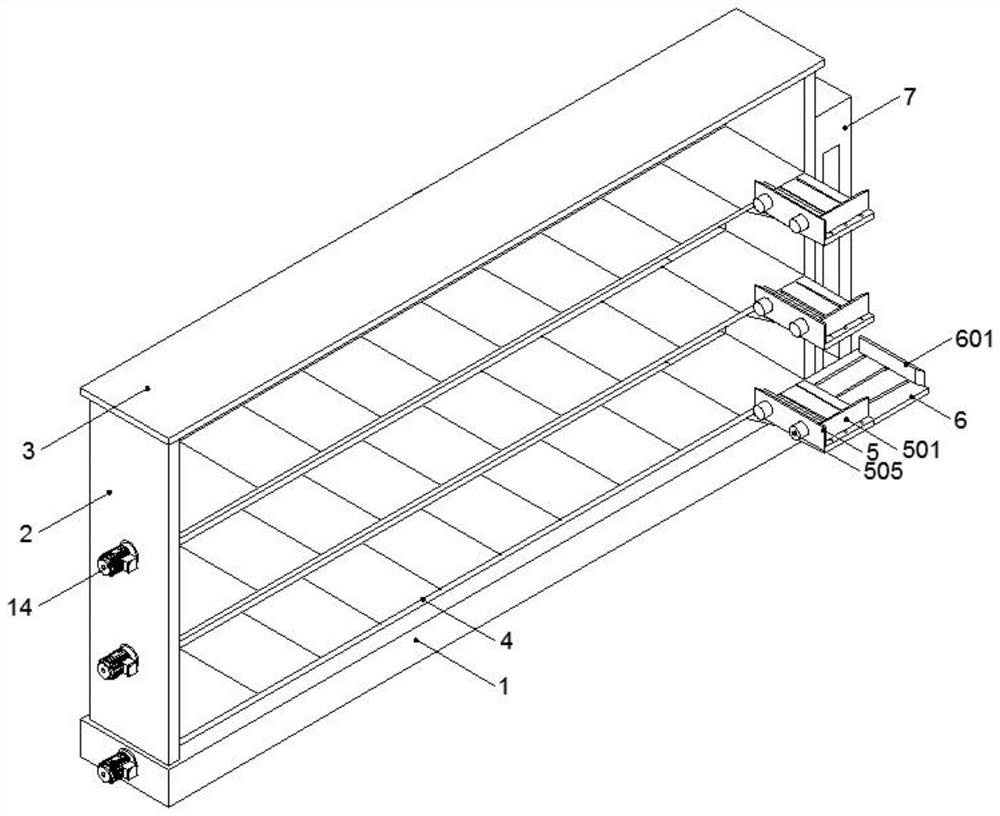

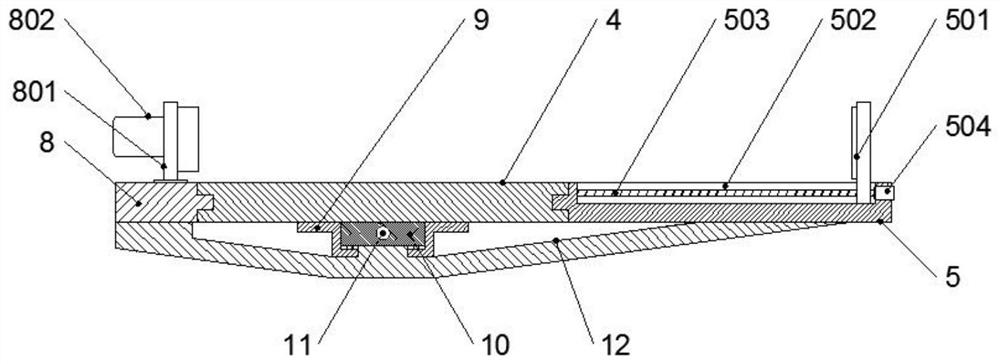

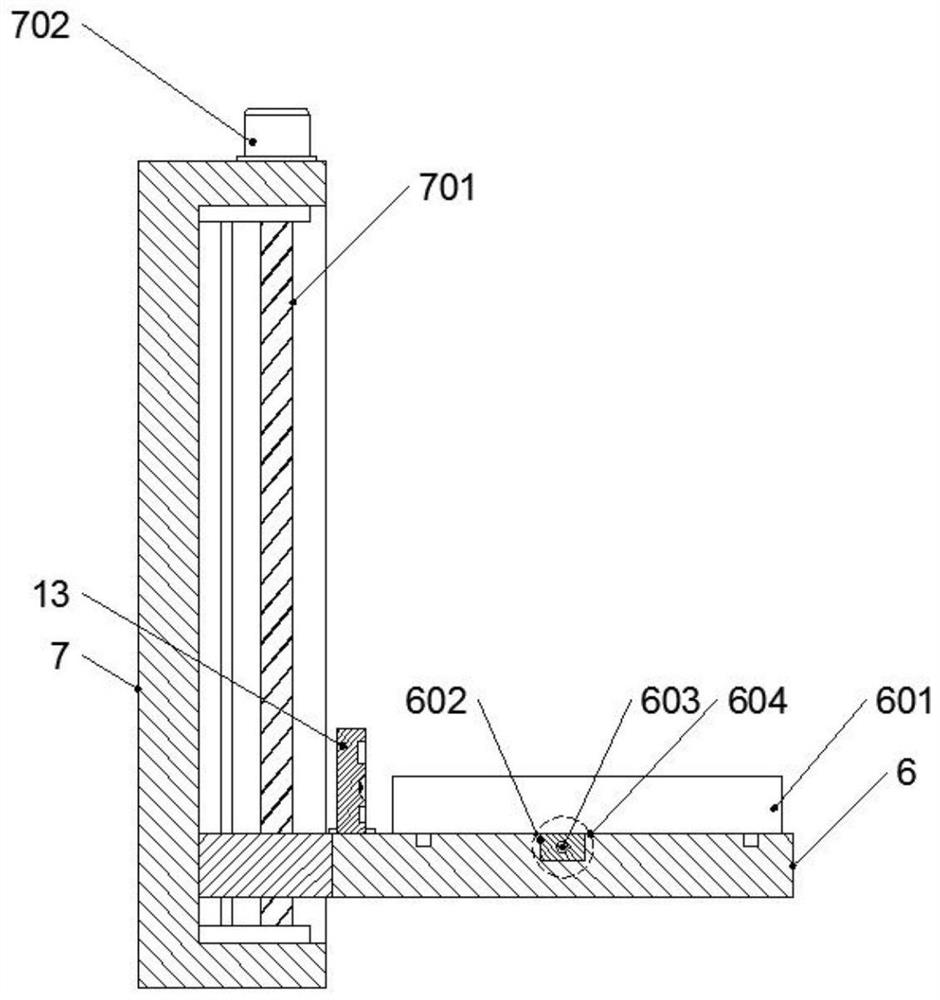

[0023] Example: such as Figure 1-5 As shown, a special shelf system for a high-precision automated three-dimensional warehouse of the present invention includes a fixed base 1, and the left and right ends of the upper end surface of the fixed base 1 are vertically fixedly connected with support plates 2, and the top ends of the support plates 2 are connected together. There is an upper fixed plate 3, the bottom of the upper fixed plate 3 is equidistantly provided with multiple sets of partitions 4, and the left and right ends of the partitions 4 are respectively fixedly connected to the support plate 2, and one side of the partition 4 All are provided with feeding table 5, and the upper end face of described feeding table 5 is equipped with first push plate 501, and described first push plate 501 is all perpendicular to support plate 2, and described feeding table 5 is close to The bottom center of the first push plate 501 is provided with a first chute 502, and a first lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com