Display module and forming method thereof

A display module and display panel technology, which is applied in character and pattern recognition, instruments, printing image acquisition, etc., can solve the problems of loss of display module yield, difficulty in ensuring the production yield of display module, and large thickness, etc., to achieve High yield, small thickness, and the effect of reducing yield loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

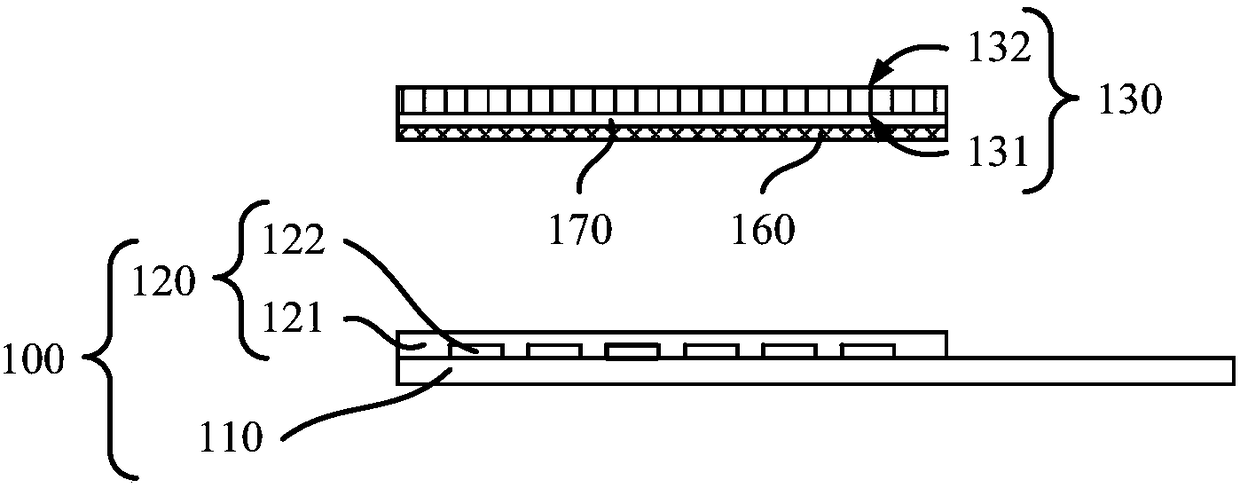

[0048] It can be seen from the background technology that the existing display modules with fingerprint recognition function are often thicker, and the existing thinning process will cause a high yield loss in the manufacturing process, making it difficult to achieve manufacturing yield and module thinning take into account.

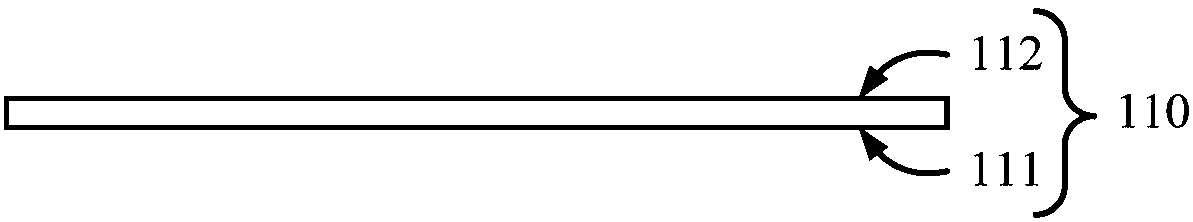

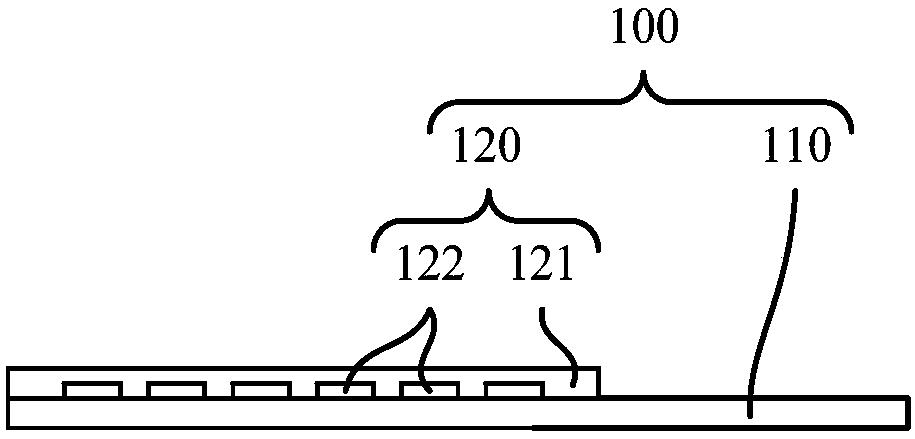

[0049] In order to solve the above-mentioned technical problems, the present invention provides a display module and its forming method, by directly forming a device layer on a flexible plastic substrate to form an optical sensor; then integrating a self-luminous display panel and protection on the optical sensor layer. The use of the flexible plastic substrate can achieve both high yield and small thickness.

[0050] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com