Safe cutting device suitable for furniture packing

A cutting device and filler technology, applied in metal processing and other directions, can solve problems such as affecting work efficiency and scalding workers' hands, and achieve the effect of improving stress conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

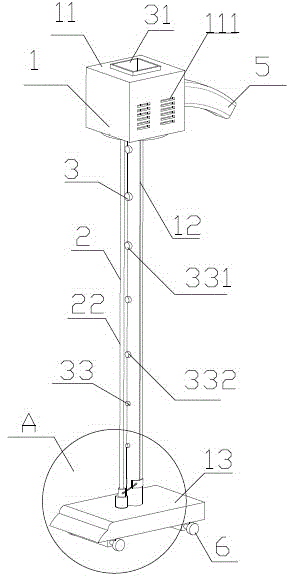

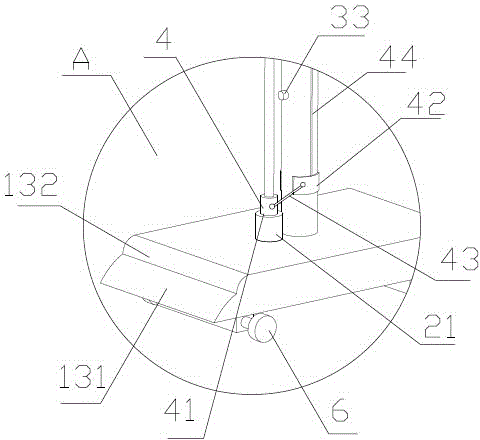

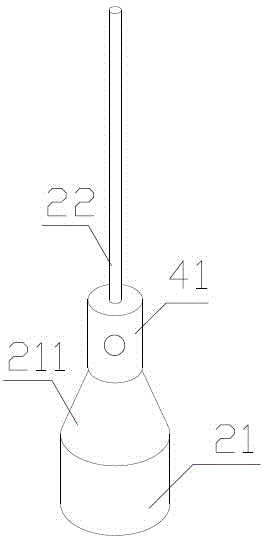

[0030] Example 1, such as figure 1 , figure 2 with image 3 Shown: a safety cutting device suitable for furniture fillings, including a frame 1 and an electric heating device 2 arranged on the frame 1, characterized in that: the safety cutting device suitable for furniture fillings also includes electric heating The oil injection device 3 for oiling the device 2 and the cleaning device 4 for cleaning the electric heating device 2 .

[0031] The frame 1 includes a base 13 that moves on the ground, an operation box 11, and a connecting column 12 that connects the operating box 11 and the base 13 and is perpendicular to the horizontal plane; Heating wire 22 for cutting filler after heating. The operation box 11 is provided with a plurality of cooling grooves 111 . The operation box 11 has a built-in power supply and other electronic components, which will generate a certain amount of heat during work, and the cooling groove 111 is required to discharge the heat in time. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com