Preparation method of composite air filter screen

An air filter and composite technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as inability to effectively filter oily smoke and dust, easy to stick to dust, easy to breed bacteria, etc., to avoid human health Hazard, effect of significant filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

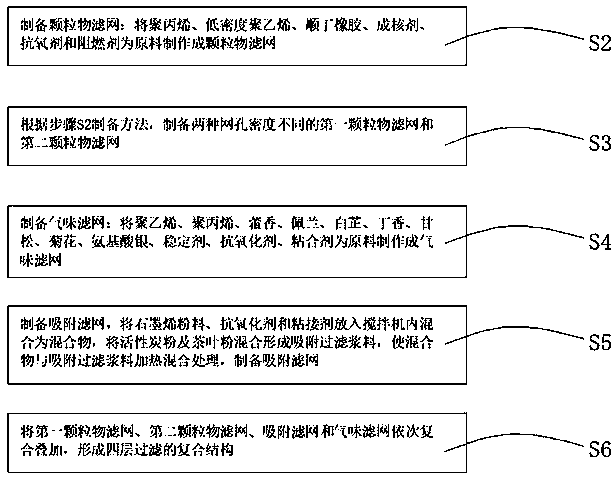

[0021] see figure 1 , the present invention provides a technical solution: a method for preparing a composite air filter comprising the following steps:

[0022] S1. The composite air filter is the first particle filter, the second particle filter, the adsorption filter and the odor filter from left to right;

[0023] S2. Preparing a particle filter: making a particle filter from polypropylene, low-density polyethylene, butadiene rubber, a nucleating agent, an antioxidant, and a flame retardant;

[0024] S3. According to the preparation method in step S2, prepare two kinds of first particulate filter and second particulate filter with different mesh densities;

[0025] S4. Preparation of odor filter: polyethylene, polypropylene, ageratum, perrin, angelica, clove, nard pine, chrysanthemum, amino acid silver, stabilizer, antioxidant and adhesive are used as raw materials to make odor filter;

[0026] S5, prepare the adsorption filter screen, put the graphene powder, antioxidan...

Embodiment 2

[0035] see figure 1 , the present invention provides a technical solution: a method for preparing a composite air filter comprising the following steps:

[0036] S1. The composite air filter is the first particle filter, the second particle filter, the adsorption filter and the odor filter from left to right;

[0037] S2. Preparing a particle filter: making a particle filter from polypropylene, low-density polyethylene, butadiene rubber, a nucleating agent, an antioxidant, and a flame retardant;

[0038] S3. According to the preparation method in step S2, prepare two kinds of first particulate filter and second particulate filter with different mesh densities;

[0039] S4. Preparation of odor filter: polyethylene, polypropylene, ageratum, perrin, angelica, clove, nard pine, chrysanthemum, amino acid silver, stabilizer, antioxidant and adhesive are used as raw materials to make odor filter;

[0040] S5, prepare the adsorption filter screen, put the graphene powder, antioxidan...

Embodiment 3

[0049] see figure 1 , the present invention provides a technical solution: a method for preparing a composite air filter comprising the following steps:

[0050] S1. The composite air filter is the first particle filter, the second particle filter, the adsorption filter and the odor filter from left to right;

[0051] S2. Preparing a particle filter: making a particle filter from polypropylene, low-density polyethylene, butadiene rubber, a nucleating agent, an antioxidant, and a flame retardant;

[0052] S3. According to the preparation method in step S2, prepare two kinds of first particulate filter and second particulate filter with different mesh densities;

[0053] S4. Preparation of odor filter: polyethylene, polypropylene, ageratum, perrin, angelica, clove, nard pine, chrysanthemum, amino acid silver, stabilizer, antioxidant and adhesive are used as raw materials to make odor filter;

[0054] S5, prepare the adsorption filter screen, put the graphene powder, antioxidan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com