Electrofusion connection pipe fitting

A technology for electrofusion pipe fittings and connecting pipe fittings, which is applied in the field of PE pipes and can solve problems such as leakage, affecting the strength and quality of pipes, and weakening the strength of sockets and sockets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

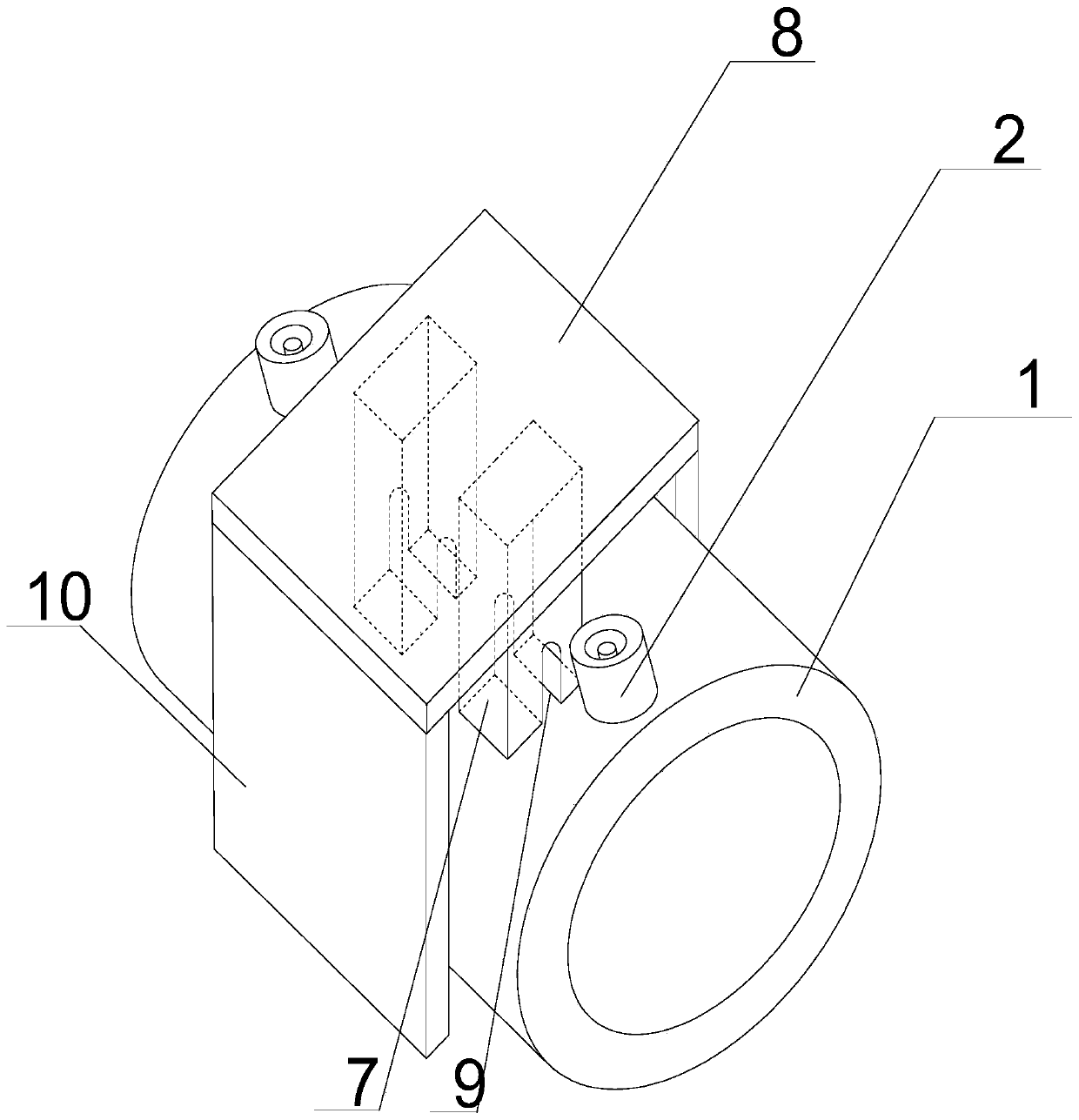

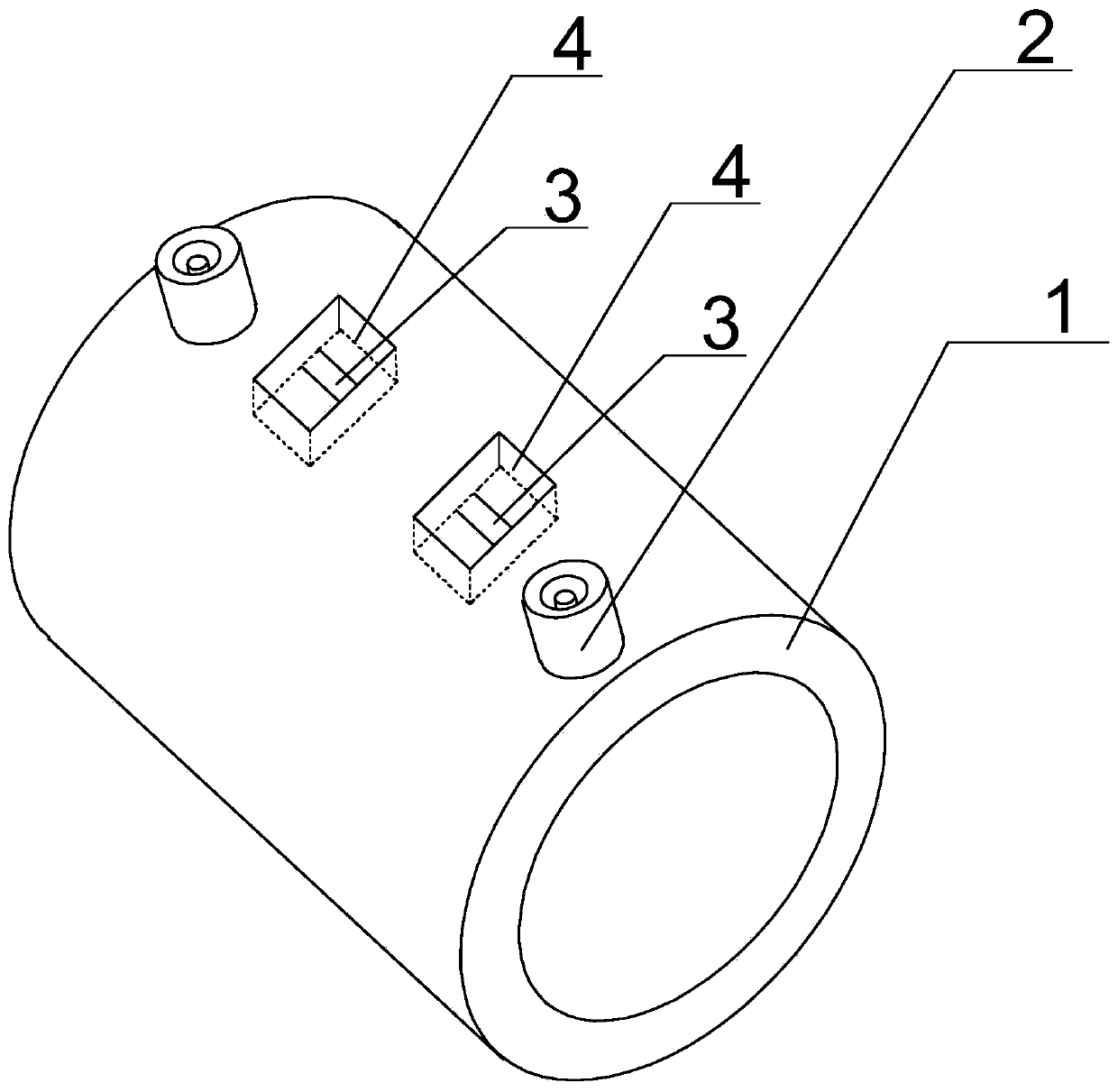

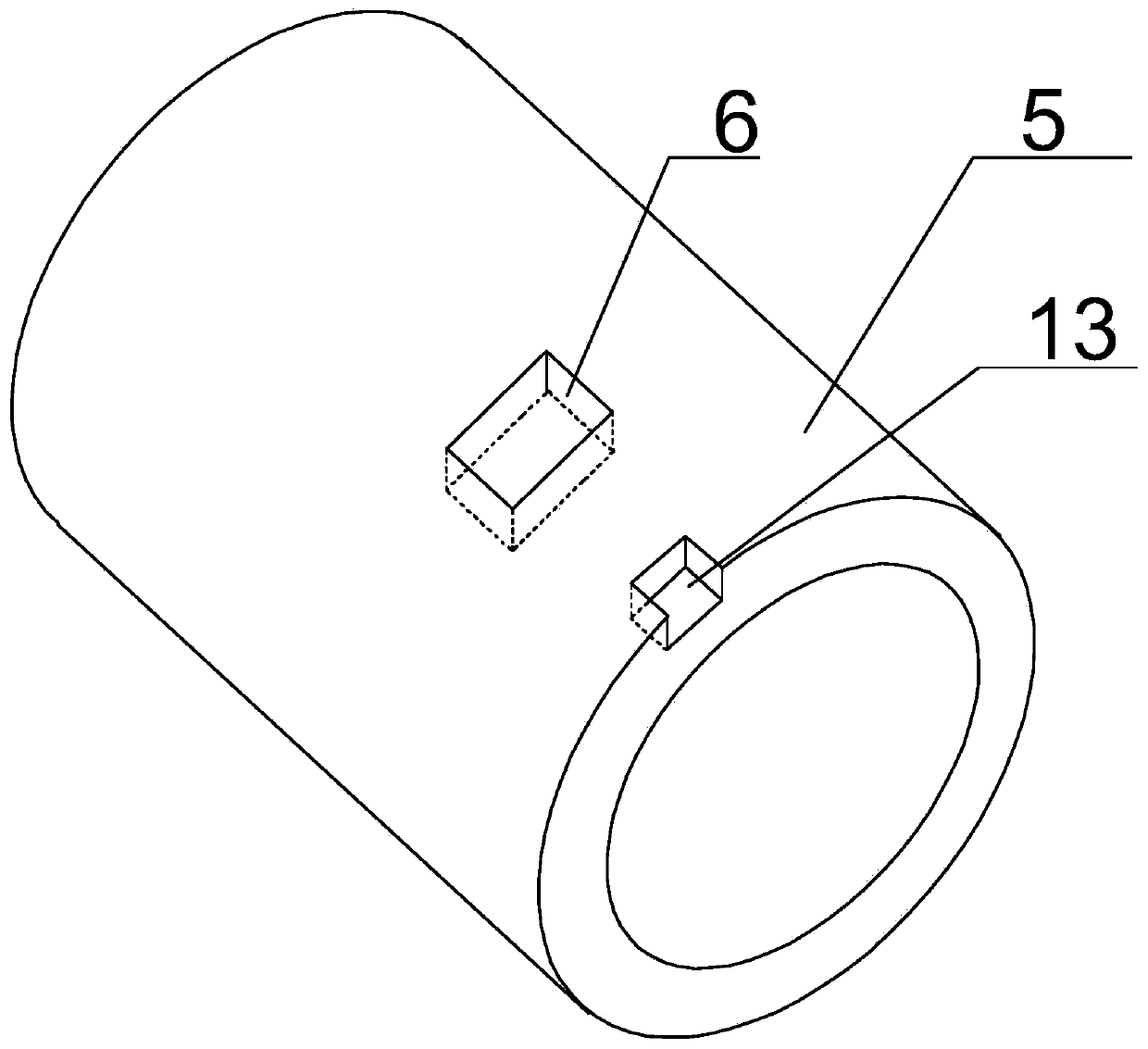

[0045] The present invention is an electrofusion connection pipe fitting, which comprises an electrofusion pipe fitting 1, a resistance wire 3 is spirally wound on the inner wall between two conductive copper columns 2 of the electrofusion pipe fitting 1, and one end of each of the two PE pipes 5 is respectively inserted into the electrofusion pipe fitting 1. Both ends of pipe fitting 1 are connected, such as figure 2 and 3 As shown, the outer wall of the electrofusion pipe fitting 1 is provided with two through grooves 4, and the two PE pipes 5 are provided with grooves 6 corresponding to the through grooves 4, as figure 1 As shown, when two PE pipes 5 are connected in the electrofusion fitting 1, the grooves 6 on the two PE pipes 5 correspond to and communicate with the two through grooves 4 respectively;

[0046] The two ends of the resistance wire 3 are respectively connected to the two conductive copper columns 2 on the electrofusion pipe fitting 1, and the middle secti...

Embodiment 2

[0052] On the basis of Example 1, when welding PE80 / PE100 pipe fittings / pipes, first ensure the temperature environment: -5°C to 40°C;

[0053] When welding, first measure and use a marking pen to mark the depth or welding area inserted into the electric fusion pipe fitting 1 on the pipe; completely remove the oxide layer in the pipe welding area before welding. The welding surface of the pipe and the electrofusion fitting 1 must be absolutely clean, dry and free from oil. Insert the welded end of the pipe into the port of the electrofusion fitting 1 to the marking depth on the PE pipe 5. At this time, the PE stopper 12 on the inner wall of the electrofusion fitting 1 is inserted into the retaining groove 13 of the PE pipe 5 to limit the position;

[0054] After inserting the PE pipe, press the reinforcing plate 8 downward, so that the fixing part 7 enters the groove 6 on the PE pipe 5 through the through groove 4, and then the PE pipe 5, the reinforcing part and the electrofu...

Embodiment 3

[0063] On the basis of Example 2, such as Figure 8 As shown, there is an elastic hollow rubber buffer tube 11 between the reinforcing plate 8, the fixing plate 10 and the outer wall of the electrofusion pipe fitting 1. For the natural gas pipeline, the PE pipe 5 of SDR17.6 and de90 made of PE100 is used; The outer diameter of the tube 5 is 90 mm.

[0064] The outer diameter of the electrofusion pipe fitting 1 is 120mm, and the thickness of the buffer pipe 11 is 6mm.

[0065] The length of the fixing part 7 in the direction perpendicular to the axis of the electrofusion pipe part 1 is three times the diameter of the resistance wire 3, and the placement groove 9 is located at the center of the length.

[0066] The depth of the groove 6 is 1.7 mm. At the same time, an inorganic gas barrier thin film layer is provided on the surface of the reinforcing plate 8 in contact with the electrofusion pipe fitting 1, and the thickness of the inorganic gas barrier thin film layer is 0.2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com