External transmission liquid seal type rotary material distribution device

A rotary distributor and liquid-sealed technology, which is applied in the direction of furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of complex structure of the overall structure drive device, non-adjustable distribution angle, and the impact of production continuity, so as to avoid furnace The effect of high temperature, reducing the loss of effective heat, and the effect of convenient and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

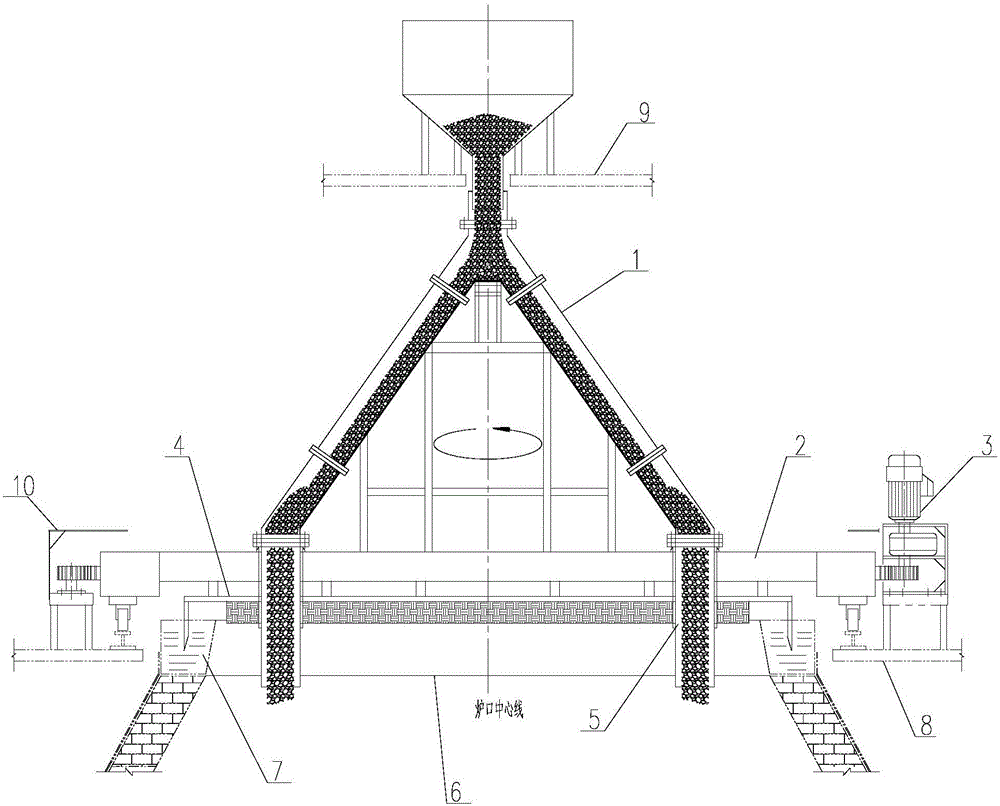

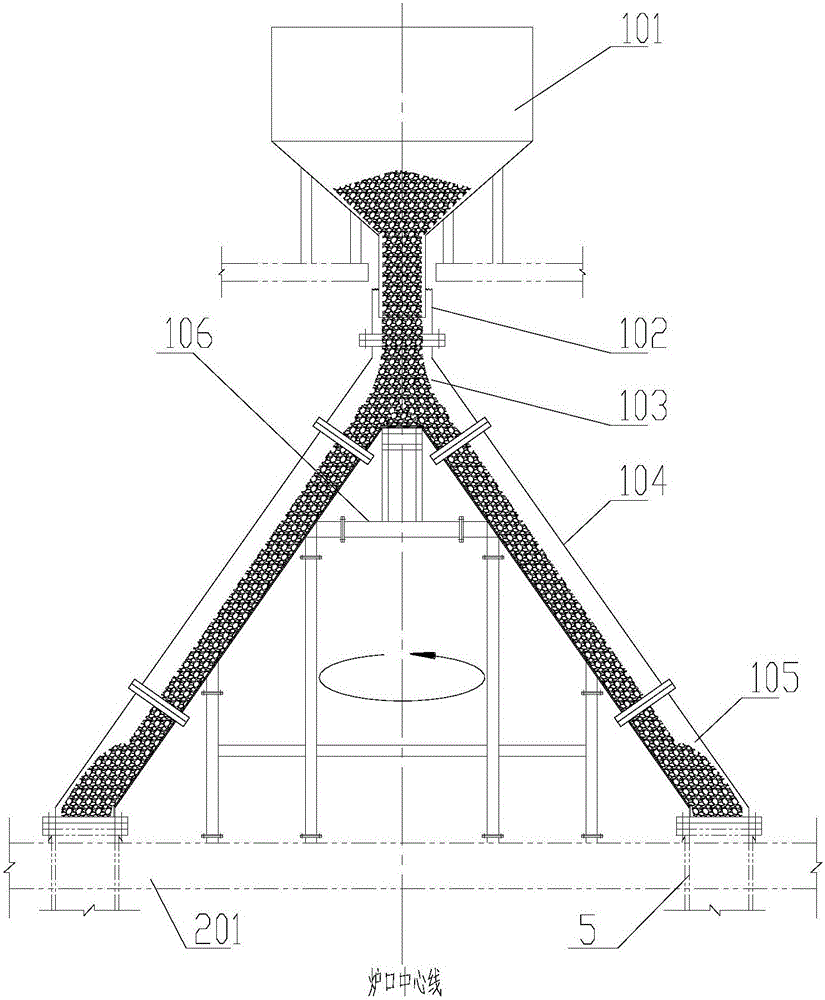

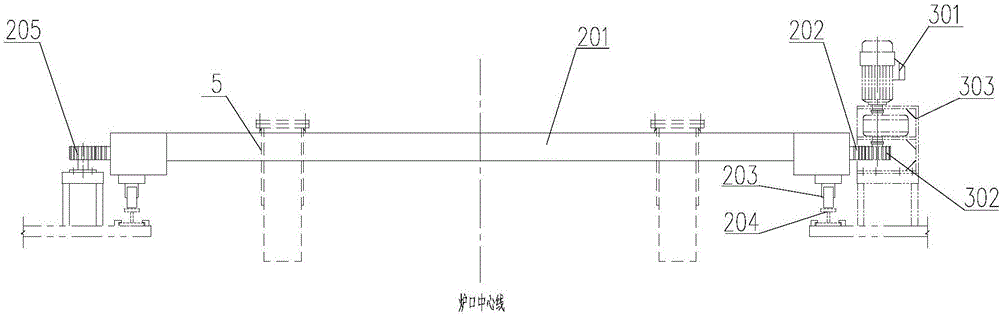

[0029] like figure 1 As shown, an externally driven liquid-sealed rotary distributor of the present invention includes a distribution device 1, a rotating device, a driving mechanism 3 and a rotating liquid seal 4; the rotating device 2 is installed on a steel On the structural platform 18, it is composed of a rotating disk 201 and a gear disk 202; the material distribution device 1 is composed of a receiving hopper 101, a sealed union pipe 102, a branch body 103, a material guide body 104 and a material discharge body connected in sequence from top to bottom. 105, as a material channel, wherein the branch body 103 is a double-fork or multi-fork structure; the material distribution device 1 except the receiving hopper 101 is fixed on the rotating disk 201 through an adjustable bracket 106, and the outer circumference of the rotating disk 201 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com