Sound insulation structure, sound insulation material and silencing device for automobile

A sound insulation material and sound insulation technology, applied in the superstructure, superstructure sub-assemblies, vehicle parts, etc., can solve the problems of infrasound wave having no effect and human body damage, etc., achieve good heat insulation ability, reduce noise to people hazard, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

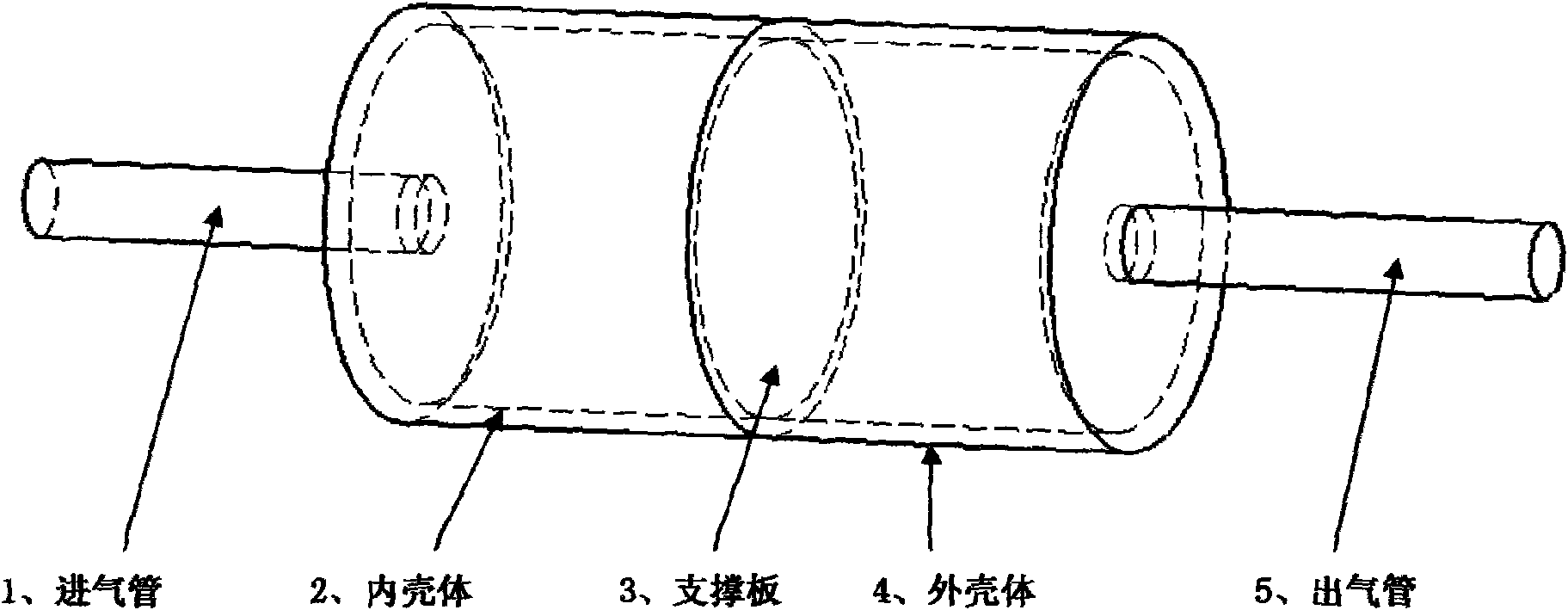

[0017] The intake and exhaust mufflers are used to reduce aerodynamic noise, but this process will inevitably produce airflow friction noise and radiation noise, especially the muffler shell with large area and low rigidity will generate a lot of radiation noise . At present, most of the shells of automobile mufflers have only one layer, or two layers close together, with some sound-absorbing materials sandwiched in between, which has obvious defects in isolating radiated noise. The invention provides a method for isolating radiation noise by vacuum, and the casing of the intake and exhaust muffler is designed as double layers, such as figure 1 As shown, the muffler device consists of an inner shell 2 and an outer shell 4. A certain gap is left in the middle, and then the interlayer is evacuated. Some supporting plates 3 are added at appropriate places, and the inner casing 2, the outer casing 4 are all sealed and connected with the air inlet pipe 1 and the air outlet pipe 5....

Embodiment 2

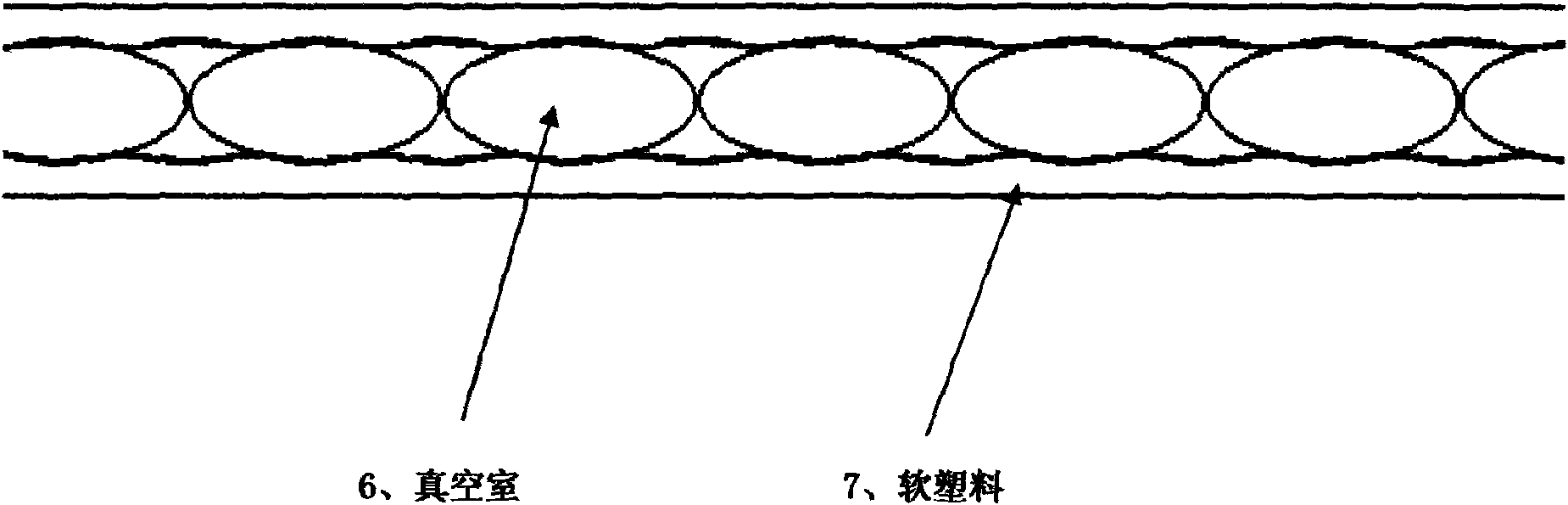

[0020] At present, automobiles adopt porous sound-absorbing materials arranged on the hood or other body parts to isolate engine radiation noise and wind noise. Acoustic effects are weak. Aiming at this defect, the present invention provides a vacuum sound insulation material, which uses phenolic plastic or other organic materials to produce a sound insulation material, and the sound insulation material adopts the structure of a small vacuum chamber 6 plus a soft plastic 7, and the middle is The flat small vacuum chambers 6 are arranged in an orderly manner according to certain rules, and the two sides are softer soft plastics 7 attached to it for protection. The production of this sound insulation material can choose phenolic plastics, which have the characteristics of high mechanical strength, hard wear resistance, heat resistance and flame retardancy, and other organic materials with similar characteristics can also be used. The vacuum layer of this sound insulation materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com