Silicon dioxide/tin oxide composite nanoparticle with nuclear shell structure and preparation method thereof

A silicon dioxide, core-shell structure technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of complex preparation process, harsh reaction conditions, difficult to control morphology, etc., and achieve simple preparation process and production cost. The effect of low and wide extinction wavelength regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

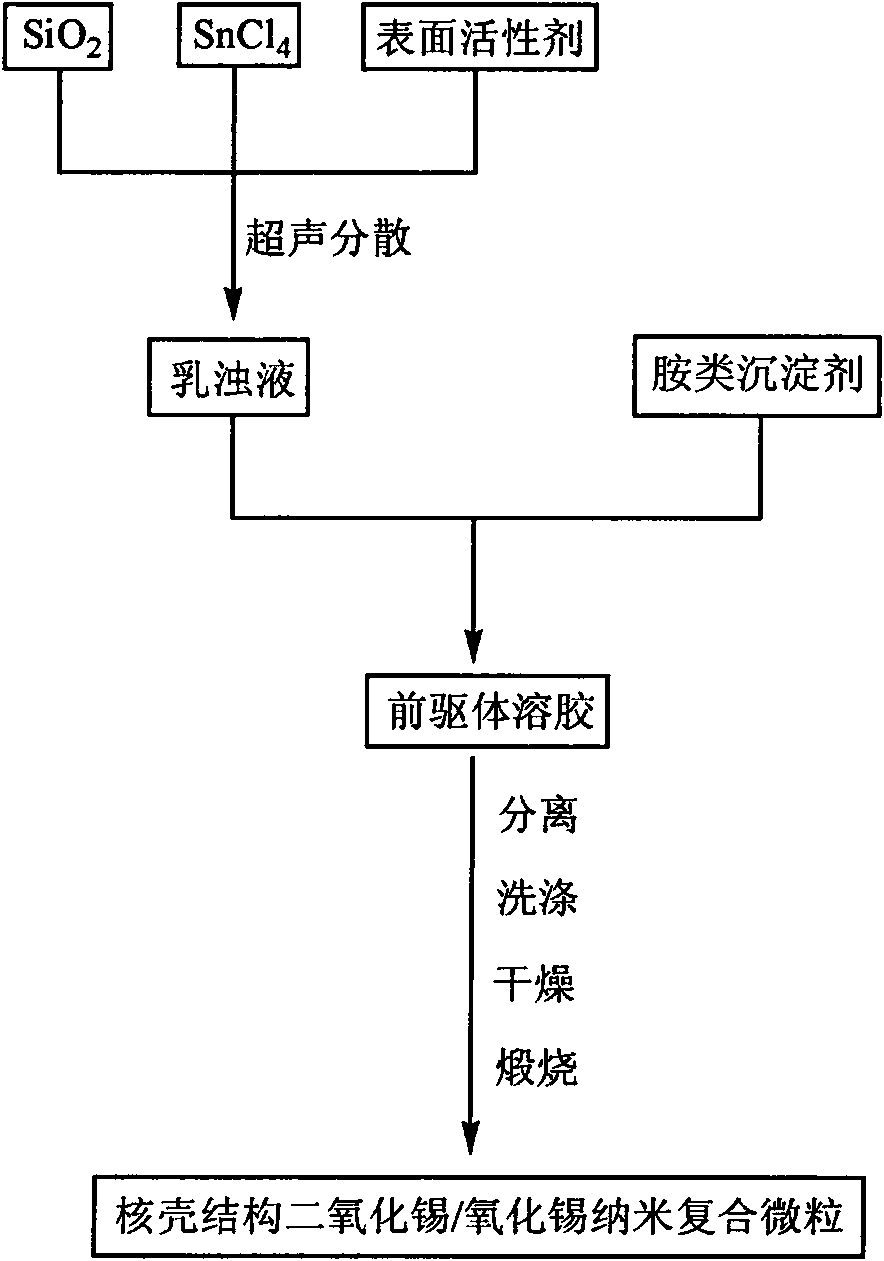

[0026] The preparation method of the silicon dioxide / tin oxide nanocomposite particles with core-shell structure in this embodiment, such as figure 1 As shown, the steps are as follows:

[0027] (1) Weigh 0.6g nano-SiO 2 Powder, 3.5gSnCl 4 .5H 2 O and 0.2 g of sodium dodecylbenzene sulfonate were dispersed in 100 ml of deionized water by ultrasonic dispersion for 30 min to obtain an emulsion. After the emulsion was stirred at 90°C for 15 minutes, 50ml of 1mol / L (NH 4 ) 2 CO 3 Solution, continue to react for 2h to obtain the precursor sol.

[0028] (2) After centrifugation, the precursor sol was washed once with deionized water and ethanol, and dried at 80°C for 12 hours to obtain the precursor powder.

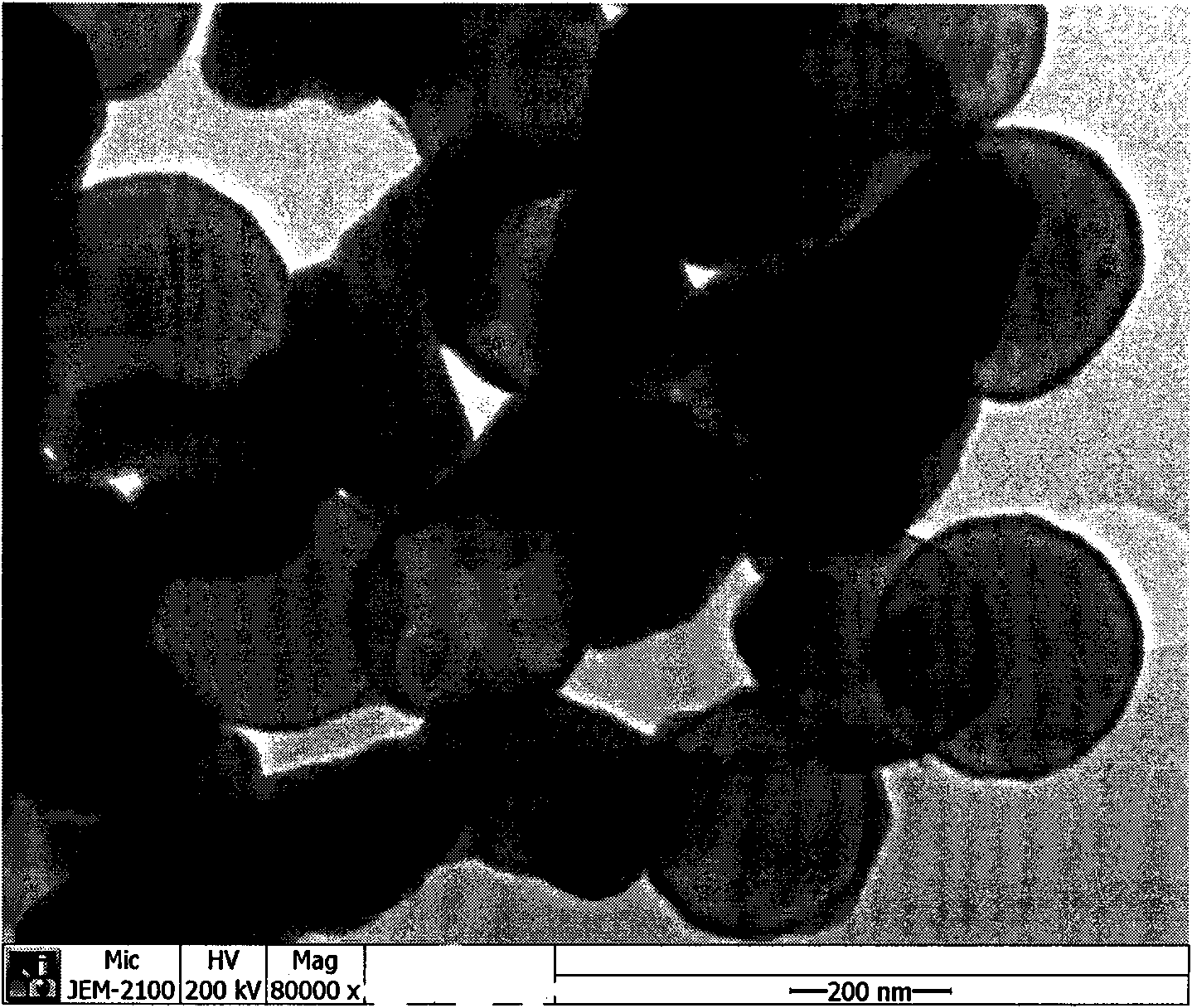

[0029] (3) The obtained white precursor powder was calcined in a muffle furnace at a temperature of 600° C. for 2 hours to obtain pale yellow silica / tin oxide nanocomposite particles with a core-shell structure.

Embodiment 2

[0031] The difference between this embodiment and the first embodiment is: SnCl 4 .5H 2 The amount of O is 7.0g; the amount of sodium dodecylbenzenesulfonate is 0.4g; the ultrasonic dispersion time is 60min; the amine precipitant (NH 4 ) 2 CO 3 The dosage of the solution is 50ml (2mol / L). The reaction time of the step (1) is 3 hours; the calcination temperature of the step (3) is 700° C., and the calcination time is 2 hours.

Embodiment 3

[0033] The difference between this embodiment and the first embodiment is: SnCl 4 .5H 2 The amount of O is 14.0g; the amount of sodium dodecylbenzenesulfonate is 0.8g; the ultrasonic dispersion time is 60min; the amine precipitant (NH 4 ) 2 CO 3The dosage of the solution is 100ml (4mol / L). The reaction time of step (1) is 4 hours; the calcination temperature of step (3) is 700° C., and the calcination time is 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com