Amorphous soft magnetic alloy coatings and preparation method thereof

A soft magnetic alloy and coating technology, applied in the direction of metal material coating process, coating, magnetic material, etc., can solve the problems of difficult to cover the surface, the coating pollutes the environment, and the preparation process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the coating of the present invention comprises the first step of preparing an alloy powder having the above-mentioned composition range;

[0038] In the second step, the powder is screened, and the powder with a particle size of 400-50 mesh, more preferably 400-100 mesh, is selected as the thermal spraying material;

[0039] In the third step, the amorphous electromagnetic shielding coating is prepared by plasma spraying or high-speed flame spraying.

[0040] In a preferred embodiment of the present invention, in the first step, the iron-based amorphous alloy powder can be prepared by atomization or milling, and the prepared powder is a pre-alloyed powder;

[0041] In the second step, the sieving of the iron-based amorphous alloy powder can be achieved by using an experimental sieve, a standard slap-type vibrating sieve, other types of vibrating sieves or air-flow powder classification equipment;

[0042] In a preferred embodiment of the prese...

Embodiment

[0049] The powders were prepared by water atomization, gas atomization, and pulverization after spraying, respectively. The powder composition is shown in Table 1. After sieving, 400-50 mesh powder is obtained, and the coating is prepared by plasma and high-speed flame spraying. The substrate is copper, and sandblasting is carried out before spraying. ) flow: 70-80L / min, hydrogen flow: 15-20L / min, spraying distance 100-120mm, powder feeding speed 50-60g / min; high-speed flame spraying process parameters: O2 pressure and flow 1.0MPa and 200-240L / min, propane pressure and flow 0.75MPa and 60~70L / min, air pressure and flow. 0.7MPa and 300~350L / min, powder feeding speed 45~55g / min, spraying distance 250mm. The process and coating properties are shown in Table 2.

[0050] Taking component 2 as an example for further specific analysis is as follows.

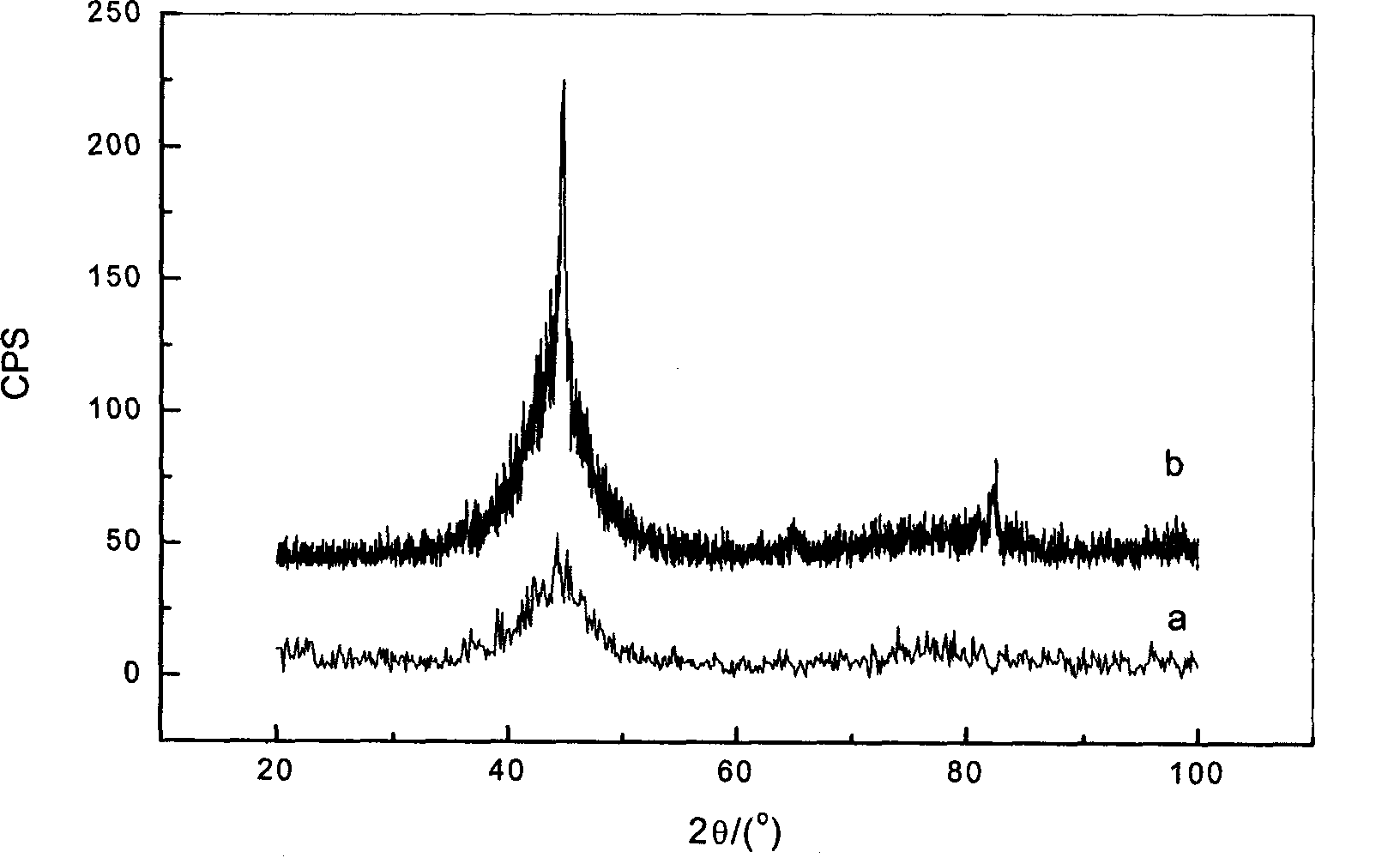

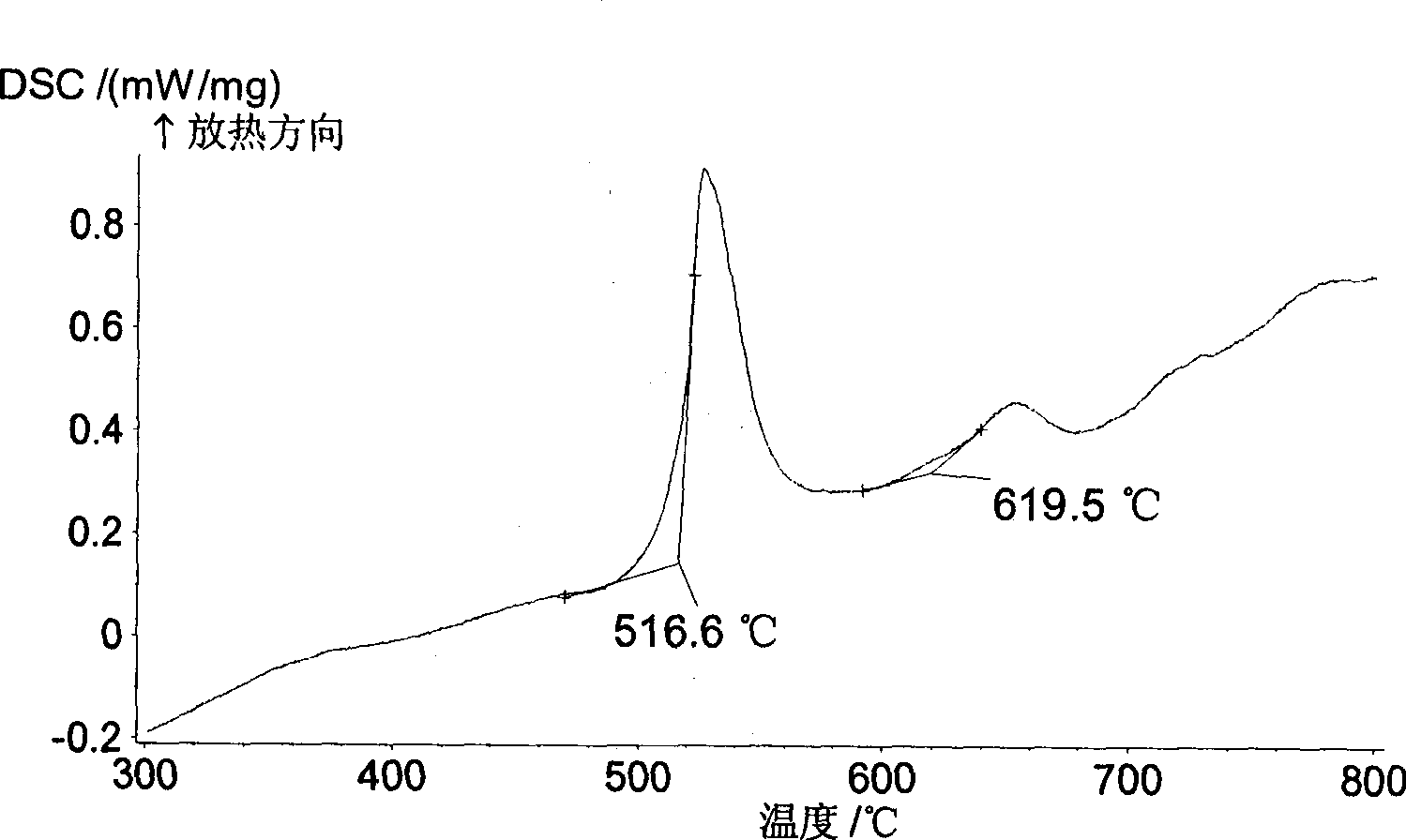

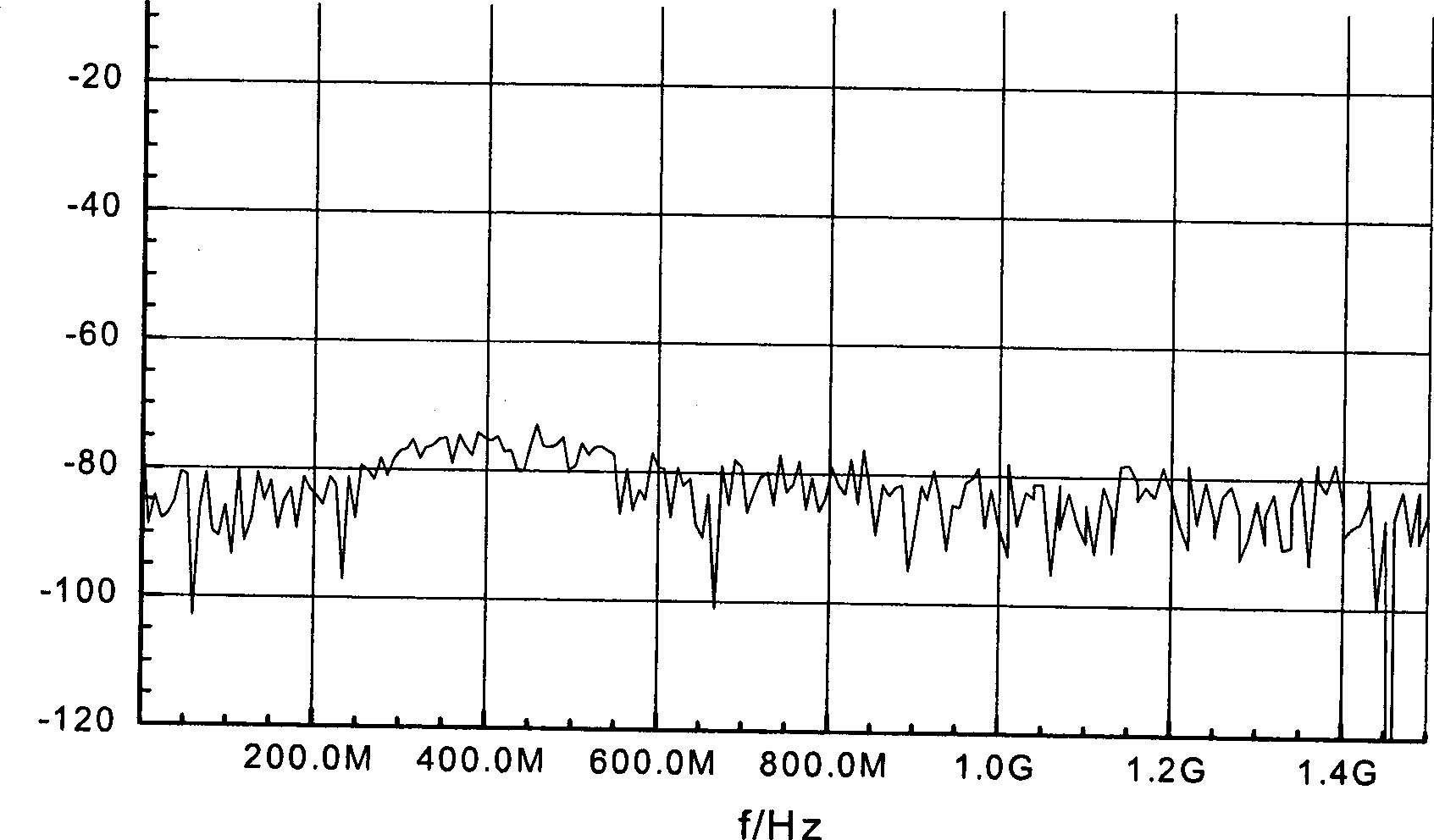

[0051] figure 1 It is the XRD diffraction pattern of No. 2 component powder (a) and sprayed layer (b), and it can be seen that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shielding effectiveness | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com