Solid phase micro-extraction extraction head using odd-tube carbon nano-tube as coating and its preparation method

A single-walled carbon nanotube, carbon nanotube technology, applied in solid solvent extraction, chemical instruments and methods, other chemical processes, etc. Affect the coating extraction efficiency and other problems, and achieve the effect of easy control of coating thickness, simple operation and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Treatment of single-walled carbon nanotubes: add single-walled carbon nanotubes to the mixed solution of sulfuric acid and nitric acid, reflux, and centrifuge the mixed solution after reflux to obtain carbon nanotube precipitates, wash with water until neutral, dry, and process The final single-walled carbon nanotubes are ready for use; the ratio of sulfuric acid: nitric acid is 7:3 by volume, the temperature of reflux is 80° C., and the time of reflux is 90 minutes.

[0036] 2) Preparation of single-walled carbon nanotube suspension: add treated single-walled carbon nanotubes in an organic solvent, disperse under the action of ultrasonic waves to obtain a carbon nanotube suspension; the concentration of the single-walled carbon nanotube suspension is 3 mg / ml, the organic solvent is methanol.

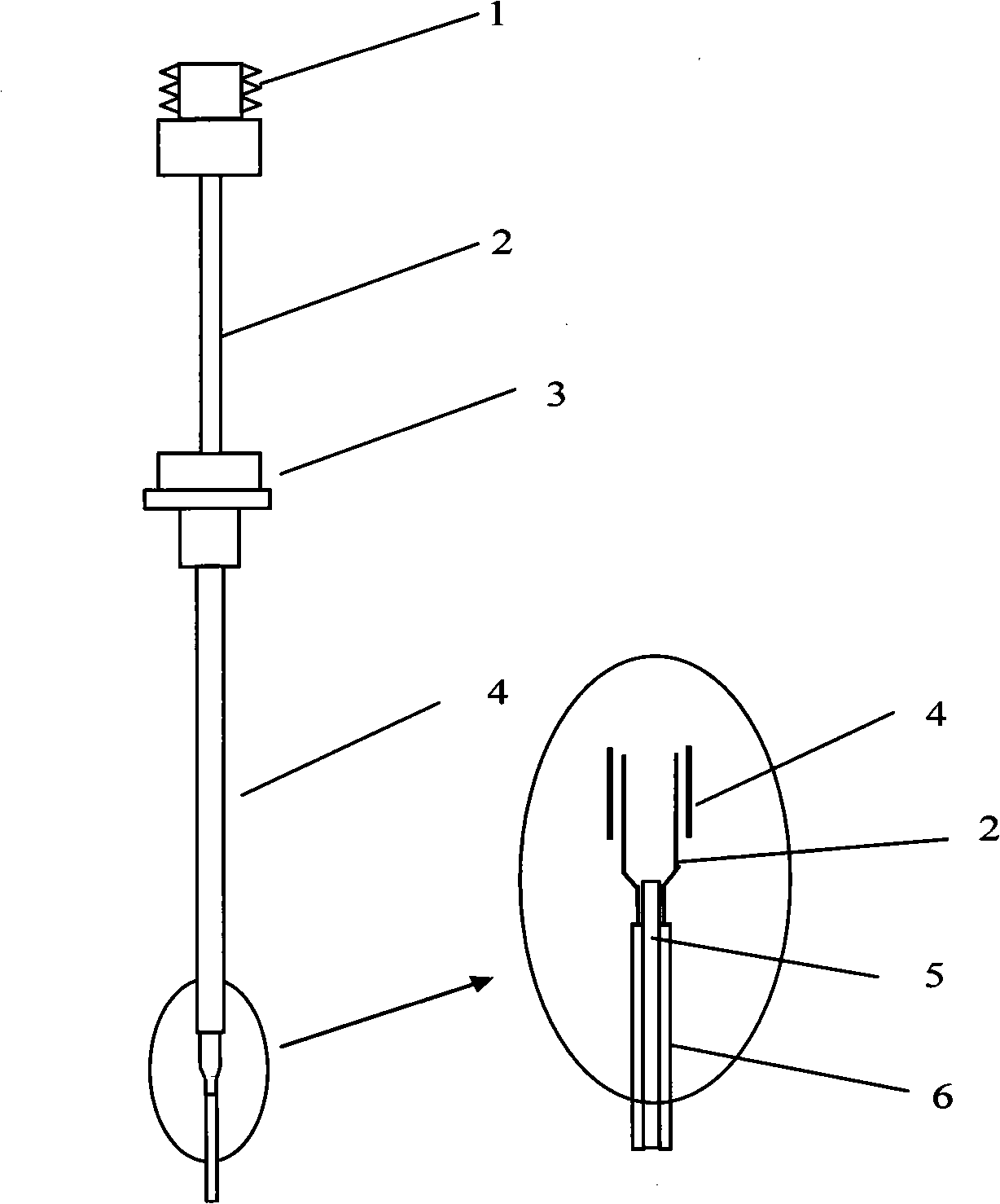

[0037] 3) Electrophoretic deposition of single-walled carbon nanotubes on platinum wires: insert two platinum wires into the carbon nanotube suspension, the distance between ...

Embodiment 2

[0040] 1) Treatment of single-walled carbon nanotubes: similar to Example 1, the difference is that the reflow temperature is 100° C., and the reflow time is 60 min.

[0041] 2) Preparation of single-wall carbon nanotube suspension: similar to Example 1, the difference is that the concentration of the single-wall carbon nanotube suspension is 0.5 mg / ml, and ethanol is selected as the organic solvent.

[0042] 3) Electrophoretic deposition of single-walled carbon nanotubes on metal wires: similar to Example 1, the difference is that the metal wires are gold wires with a spacing of 0.5 cm, and a 5V DC voltage is added between two gold wires to carry out carbon deposition. For the electrophoretic deposition of nanotubes, carbon nanotubes were gathered around the anode gold wire after continuous power-on for 10.0min, and the anode gold wire was taken out and dried at 100°C.

[0043] Step 4) is the same as step 4) of Example 1.

Embodiment 3

[0045] 1) Treatment of single-walled carbon nanotubes: similar to Example 1, the difference is that the reflow temperature is 150° C., and the reflow time is 10 min.

[0046] 2) Preparation of single-walled carbon nanotube suspension: similar to Example 1, the difference is that the concentration of the single-walled carbon nanotube suspension is 5 mg / ml, and the organic solvent is isopropanol.

[0047] 3) Electrophoretic deposition of single-walled carbon nanotubes on metal wires: similar to Example 1, the difference is that the metal wires are stainless steel wires with a spacing of 2cm, and a 100V DC voltage is added between the two stainless steel wires to carry out carbon nanotube deposition. For electrophoretic deposition of tubes, carbon nanotubes gather around the anode stainless steel wire after continuous energization for 0.1min. Take out the anode stainless steel wire and dry it at 150°C.

[0048] Step 4) is the same as step 4) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com