Aluminum product coated with nitrogen-doped graphene/nitrogen-doped TiO2 photo-catalytic material

A nitrogen-doped graphene, photocatalytic material technology, applied in the field of photocatalytic materials, can solve the problems of unsuitability for indoor photocatalysis, inevitable low efficiency, low crystallinity, etc., achieve high surface-loaded free charge density, facilitate adsorption and The effect of decomposition, strong absorption edge redshift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

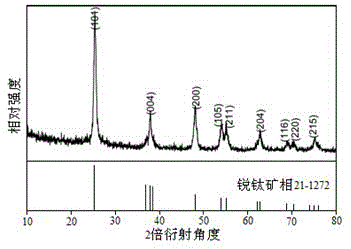

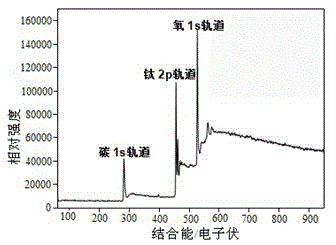

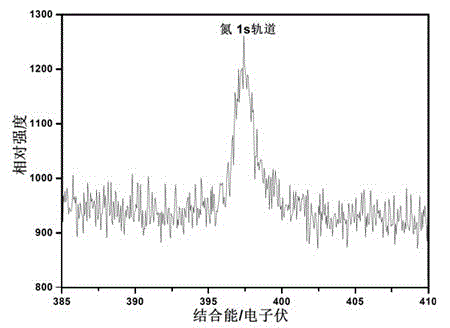

[0028] Graphene oxide (GO) was prepared by the method disclosed in ACS Nano. 2010, 4(8): 4806-4814; 60 mg of the graphene oxide was weighed, 20 mL of deionized water was added, and ultrasonically dispersed for 1 hour to obtain graphene oxide dispersion Then add 0.56g of HMT and 6.76m of titanium trichloride solution, stir on a magnetic stirrer for 0.5 hours to mix evenly, and then ultrasonic for 0.5 hours, and finally transfer the solution into a 50mL hydrothermal kettle for 16 hours of hydrothermal reaction at 180°C. The obtained precipitates were successively washed by centrifugation with deionized water and ethanol, and dried in vacuum at a temperature of 60 °C for 12 hours to obtain nitrogen-doped graphene / nitrogen-doped TiO 2 Composite photocatalytic material; the nitrogen-doped graphene / nitrogen-doped TiO 2 X-ray diffraction spectra of composite photocatalytic materials, such as figure 1 as shown, figure 1 show that the nitrogen-doped graphene / nitrogen-doped TiO 2 Nit...

Embodiment 2

[0037] Graphene oxide (GO) was prepared by the method disclosed in the document ACS Nano. 2010, 4(8): 4806-4814), and 80 mg of the graphene oxide was added to 25 mL of deionized water, and ultrasonically dispersed for 1.5 hours to obtain a graphene oxide dispersion ; Add 0.28g hexamethylenetetramine and 3.38mL titanium trichloride solution respectively in the graphene oxide dispersion, stir on a magnetic stirrer for 1 hour, mix well, then ultrasonically stir for 1 hour, then transfer the solution to In a hydrothermal kettle, at a temperature of 160°C, the hydrothermal reaction was carried out for 20 hours, and the obtained precipitates were successively washed with deionized water and ethanol by centrifugation, and then dried in vacuum at a temperature of 50°C for 10 hours to obtain nitrogen-doped Heterographene / nitrogen-doped TiO 2 Composite photocatalytic material; the aluminum profile to be coated is ultrasonically cleaned with acetone, water, and ethanol for 30 minutes, an...

Embodiment 3

[0039] Graphene oxide (GO) was prepared by the method disclosed in the document ACS Nano. 2010, 4(8): 4806-4814), and 8 mg of the graphene oxide was added to 15 mL of deionized water, and ultrasonically dispersed for 1.25 hours to obtain a graphene oxide dispersion ; Add 1.12g hexamethylenetetramine and 13.52mL titanium trichloride solution respectively in the graphene oxide dispersion, stir on a magnetic stirrer for 0.75 hours, mix well, then ultrasonically stir for 0.75 hours, then transfer the solution to In a hydrothermal kettle, at a temperature of 200°C, the hydrothermal reaction was carried out for 12 hours, and the obtained precipitates were successively washed with deionized water and ethanol by centrifugation, and then dried in vacuum at a temperature of 70°C for 8 hours to obtain nitrogen-doped Heterographene / nitrogen-doped TiO 2 Composite photocatalytic material; the aluminum profile to be coated is ultrasonically cleaned with acetone, water, and ethanol for 10 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com