Graphene oxide-containing anticorrosive paint special for steel structure and preparation method thereof

A technology for anti-corrosion coatings and steel structures, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of high content of polyphenylene sulfide resin, low surface tension of pure fluorine coatings, and uneven coating thickness. Achieve the effect of good adhesion, favorable double base disproportionation and stable polymer quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

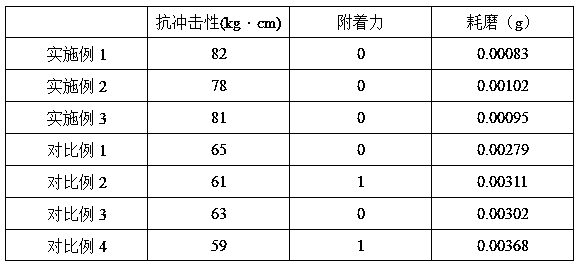

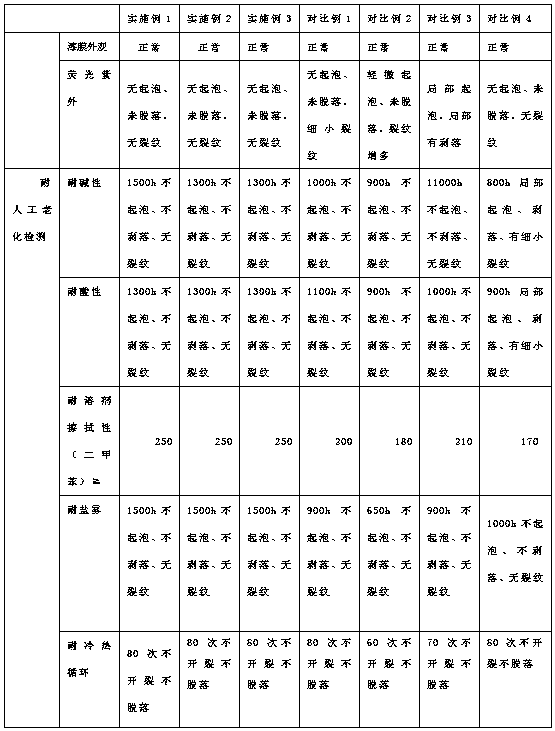

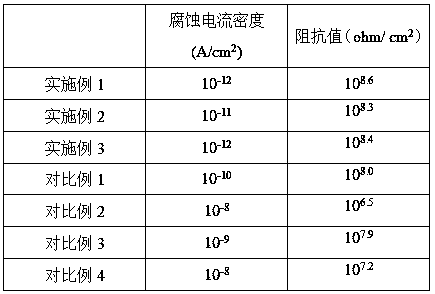

Examples

Embodiment 1

[0040] A special anti-corrosion coating for steel structures containing graphene oxide. The formula of the primer is: 30 parts of epoxy resin, 13 parts of n-butyl titanate, 8 parts of chromium acetylacetonate, 10 parts of polyvinyl formal, and 90 parts of zinc powder ;

[0041] The topcoat formula is: 70 parts of tetrafluoroethylene, 20 parts of graphene oxide, 15 parts of styrene, 5 parts of acrylic acid, 13 parts of methyl isobutyl ketone, 0.8 parts of azobisisobutyronitrile, and 0.5 parts of dibutyltin dilaurate .

[0042] The graphene oxide is prepared by the following method:

[0043] (1) Disperse graphene in a triethanolamine-ethanol solution with a volume concentration of 60-65%. The concentration of graphene is 10mg / mL. Stir evenly. Add concentrated sulfuric acid at 0-2°C. The concentration in the solution is 0.05g / mL, keep stirring, then add 2.5g sodium nitrate and 10g potassium permanganate for every 5g graphene, keep stirring for 90min to obtain the pretreatment sol...

Embodiment 2

[0053] A special anti-corrosion coating for steel structures containing graphene oxide, the primer formula is: 32 parts of epoxy resin, 15 parts of n-butyl titanate, 9 parts of chromium acetylacetonate, 8 parts of polyvinyl formal, and 100 parts of zinc powder ;

[0054] The topcoat formula is: 65 parts of tetrafluoroethylene, 25 parts of graphene oxide, 12 parts of styrene, 3 parts of acrylic acid, 12 parts of methyl isobutyl ketone, 0.9 parts of azobisisobutyronitrile, and 0.6 parts of dibutyltin dilaurate .

[0055] The preparation method is the same as in Example 1.

Embodiment 3

[0057] A special anti-corrosion coating for steel structures containing graphene oxide. The primer formula is: 35 parts of epoxy resin, 12 parts of n-butyl titanate, 10 parts of chromium acetylacetonate, 8 parts of polyvinyl formal, and 100 parts of zinc powder ;

[0058] The topcoat formula is: 68 parts of tetrafluoroethylene, 25 parts of graphene oxide, 13 parts of styrene, 5 parts of acrylic acid, 15 parts of methyl isobutyl ketone, 1.0 parts of azobisisobutyronitrile, 0.5 parts of dibutyltin dilaurate .

[0059] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com