C/C composite material superhigh temperature ceramic coating, and preparation method thereof

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of preparation of ultra-high temperature thermal protection structures, can solve the problems of poor thermal shock resistance of ceramic coatings, weak bonding force of matrix materials, and easy cracking, etc., so as to improve the overall bonding ability. And thermal shock resistance, good oxidation resistance and ablation resistance, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

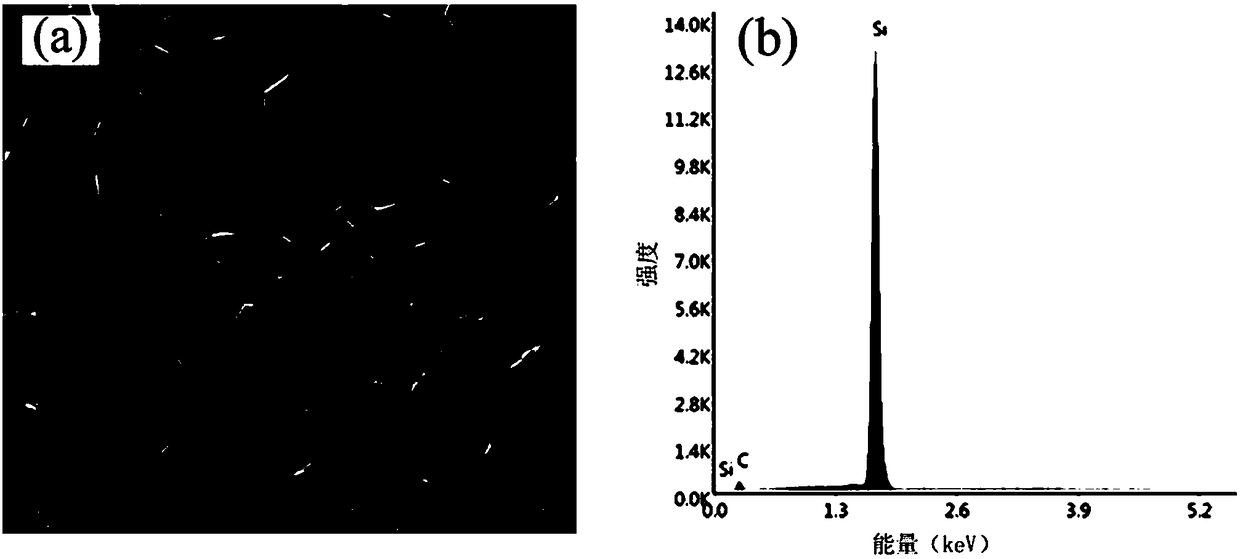

[0029] Set the density to 1.73g / cm 3 The C / C composite material is processed into a pre-coated sample, the surface is polished with sandpaper, put into anhydrous ethanol for ultrasonic cleaning, and cleaned twice, and the cleaning time is 10 minutes each time; after cleaning, put it in a drying oven for drying. .

[0030] Si and SiO 2 Mix the powder according to the mass ratio of 2:1 to obtain the mixed powder; then put the C / C composite material sample and the above mixed powder into the graphite crucible. When placed, the distance between the C / C composite material and the mixed powder is 50mm. Put the graphite crucible with mixed powder and C / C sample into a high-temperature graphitization furnace, evacuate to below 0.8kPa, fill in an inert gas as a protective gas, and raise the temperature to 2100°C at a heating rate of 10°C / min. After 2 hours of heat preservation, the temperature was naturally lowered to room temperature, and a C / C composite material with a SiC coating ...

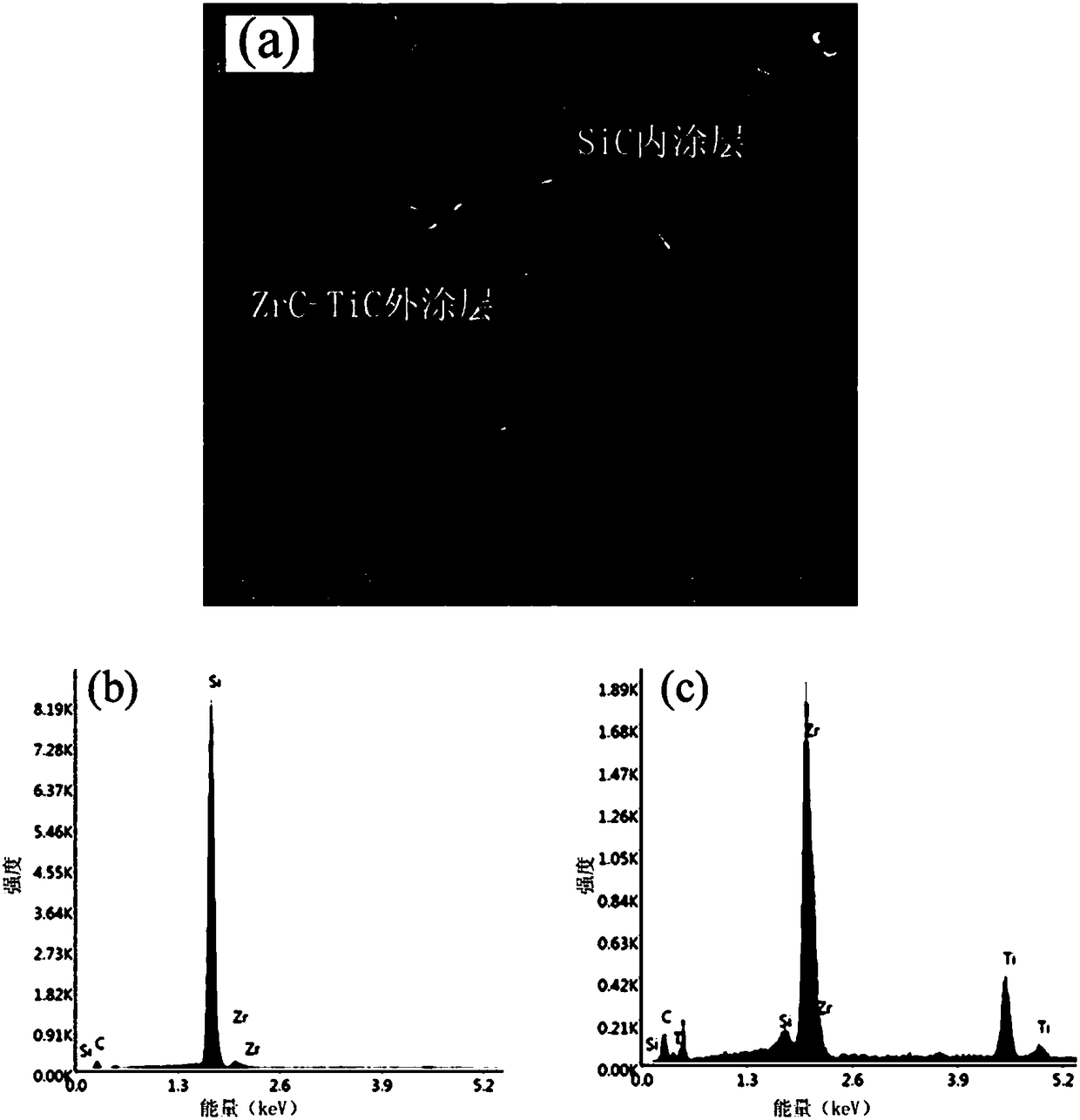

Embodiment 2

[0036] Set the density to 1.78g / cm 3 The C / C composite material is processed into a pre-coated sample, the surface is polished with sandpaper, put into anhydrous ethanol for ultrasonic cleaning, and cleaned twice, and the cleaning time is 10 minutes each time; after cleaning, put it in a drying oven for drying. .

[0037] Si and SiO 2 Mix evenly according to the mass ratio of 2:1 to obtain mixed powder; then put the C / C composite material sample and the above mixed powder into a graphite crucible. When placed, the distance between the C / C composite material sample and the mixed powder is 45mm. Then put the graphite crucible with mixed powder and C / C sample into the high-temperature graphitization furnace, evacuate to below 0.8kPa, fill in inert gas as protective gas, and raise the temperature to 2200 at a heating rate of 5°C / min. ℃, heat preservation for more than 2 hours, and then naturally cool down to room temperature to obtain a C / C composite material with a SiC coating,...

Embodiment 3

[0041] Set the density to 1.82g / cm 3 The C / C composite material is processed into a pre-coated sample, the surface is polished with sandpaper, put into anhydrous ethanol for ultrasonic cleaning, and cleaned twice, each cleaning time is 15 minutes; after cleaning, put it in a drying oven to dry for later use .

[0042] Si and SiO 2 Mix evenly according to the mass ratio of 1.2:1 to obtain the mixed powder, then put the C / C composite material sample and the above mixed powder into the graphite crucible. When placed, the distance between the C / C composite material sample and the mixed powder is 40mm. Then put the graphite crucible with mixed powder and C / C sample into the high-temperature graphitization furnace, evacuate to below 0.8kPa, fill in an inert gas as a protective gas, and raise the temperature to 2000 at a heating rate of 15°C / min. ℃, heat preservation for more than 2 hours, and then naturally cool down to room temperature to obtain a C / C composite material with a Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com