Optical fiber temperature sensor and preparation method of cadmium sulfide films of optical fiber temperature sensor

An optical fiber temperature and cadmium sulfide technology, applied in the field of sensors, can solve the problems of complex coating, cutting and packaging processes, high cost of temperature demodulation system, lack of light absorption performance, etc., and achieves simple coating and manufacturing process and high accuracy , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a cadmium sulfide thin film for an optical fiber temperature sensor. CBD (chemical water bath method) is used to prepare a cadmium sulfide thin film. Multiple or continuous deposition, so the thickness of the grown film is controllable. The chemical reaction mechanism of preparing cadmium sulfide film is: based on the decomposition of thiourea in alkaline solution containing cadmium salt, the deposition of cadmium sulfide film. After deposition, it is annealed in a high-temperature oven at 200°C to make the film more uniform, denser and smoother.

[0033] Specific steps include:

[0034] Step S1: Fixing the Fiber

[0035] Fix the optical fiber with an optical fiber ferrule, inject high-temperature-resistant, soluble glue into the ferrule, and cure the glue so that the optical fiber and the ferrule are tightly fixed without loosening.

[0036] Step S2: Grinding the fiber

[0037] After curing, use an optical fiber grinder...

Embodiment approach

[0039] Use the previous chemical water bath method to coat the exposed end face of the optical fiber with the end face aligned with the ferrule with a cadmium sulfide film. The coating method is as follows:

[0040] (1) Get a certain quality of thiourea and dissolve it in deionized water, numbering solution A;

[0041] (2) Get a certain quality of cadmium sulfate and dissolve it in deionized water, numbering solution B;

[0042] (3) Measure 40-50mL of ammonia water with a mass fraction of 28%-35%, add it to solution B and stir, and number solution C;

[0043] (4) Measure a certain volume of deionized water and pour it into the reactor, then pour solution A and solution C into the reactor and mix to form a reaction solution, and immerse the exposed end face of the optical fiber in the reaction solution. Put the reactor into a water bath, set the reaction temperature to 60-70°C, and the reaction time to 9 minutes. At this point, the primary coating is completed;

[0044] (5) B...

Embodiment 1

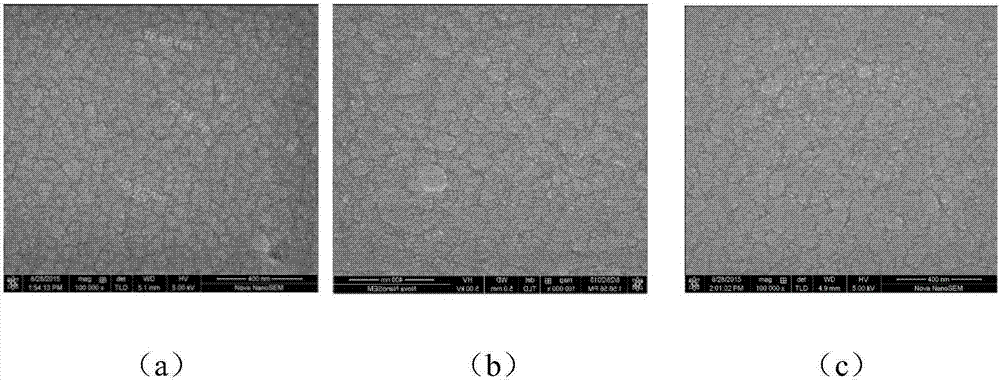

[0051] Examples 1-8 all realized the deposition of cadmium sulfide film. Wherein, embodiment 1, embodiment 2, embodiment 3 obtain the scanning electron microscope picture of cadmium sulfide film respectively with reference to figure 1 (a)(b)(c), represented by figure 1 It can be seen that the molecular particles of the cadmium sulfide film obtained in Example 1 are smaller, more uniform and denser.

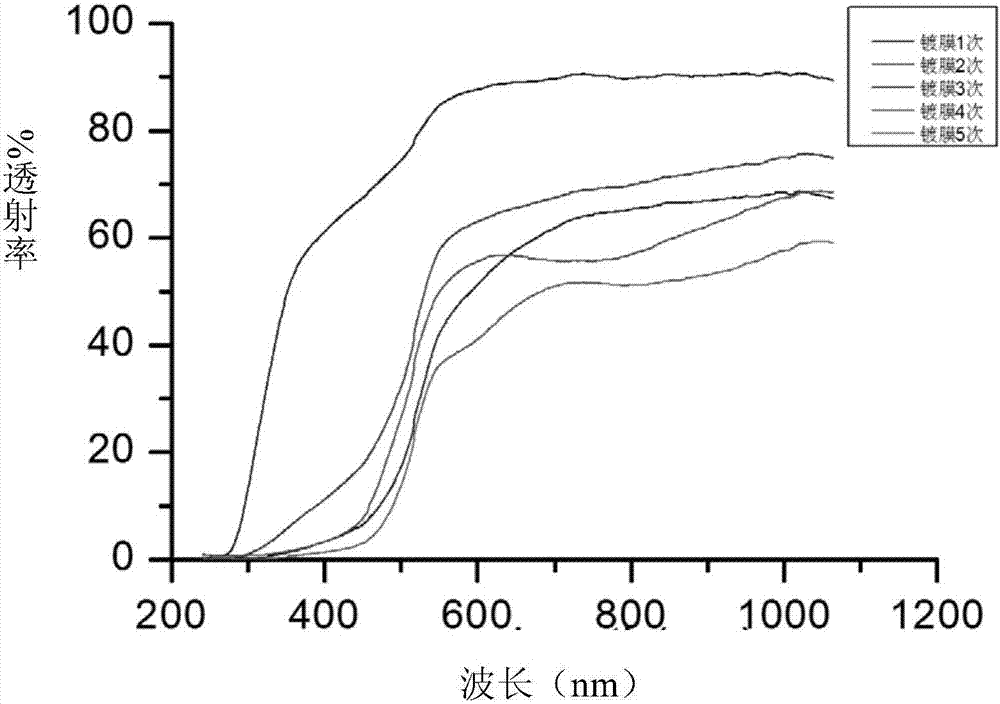

[0052]In addition, in conjunction with Examples 4-8, it can be seen that on the basis of the same reaction conditions, 4 layers, 1 layer, 2 layers, 3 layers and 5 layers of cadmium sulfide films were deposited respectively, and then by testing the cadmium sulfide films of different thicknesses transmittance spectrum. see figure 1 As shown, it can be seen that the absorption edge of the transmittance line is the best when the film is coated 4 times (the cadmium sulfide film has four layers).

[0053] Next, two different optical fiber temperature sensors were prepared using the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com