Metal-organic framework material coated ternary positive electrode material and preparation method thereof

A cathode material and organic framework technology, applied in the field of new energy materials, can solve the problems of corrosion and irreversible side reactions of electrolyte, and achieve the effect of increasing capacity, excellent cycle stability, and preventing the contact of cathode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

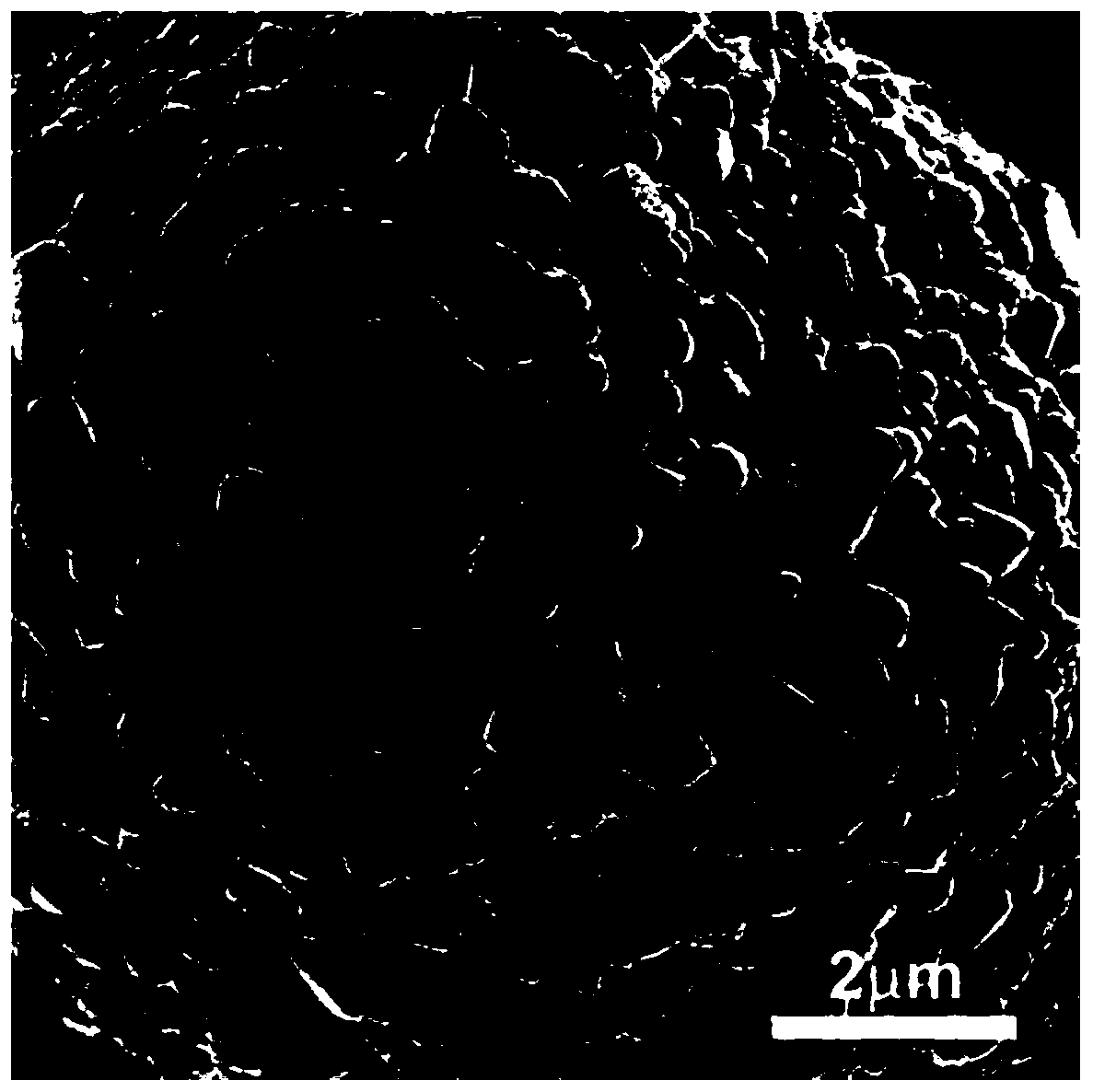

[0034] In this embodiment, the preparation method of metal-organic framework material-coated ternary cathode material includes the following steps:

[0035] (1) 500mg ternary cathode material LiNi 0.6 co 0.2 mn 0.2 0 to 50ml of absolute ethanol and N,N-dimethylformamide mixed solution, the volume ratio of absolute ethanol and N,N-dimethylformamide is 1:49, stirred for 1h to obtain the first dispersion;

[0036] (2) Under stirring conditions, 35 μl of zirconium n-propoxide (70wt.% n-propanol solution), 42 mg of benzoic acid, and 12 mg of terephthalic acid were added to the first dispersion, and stirred for 2 hours to obtain a uniformly stirred second dispersion liquid. Wherein the molar ratio of zirconium atom, benzoic acid, terephthalic acid is 1:12:2.5;

[0037] (3) Transfer the uniform dispersion in (2) to a reaction kettle with a polytetrafluoroethylene liner for solvothermal reaction. The reaction condition is 120 ° C for 8 hours, and the temperature is naturally coole...

Embodiment 2

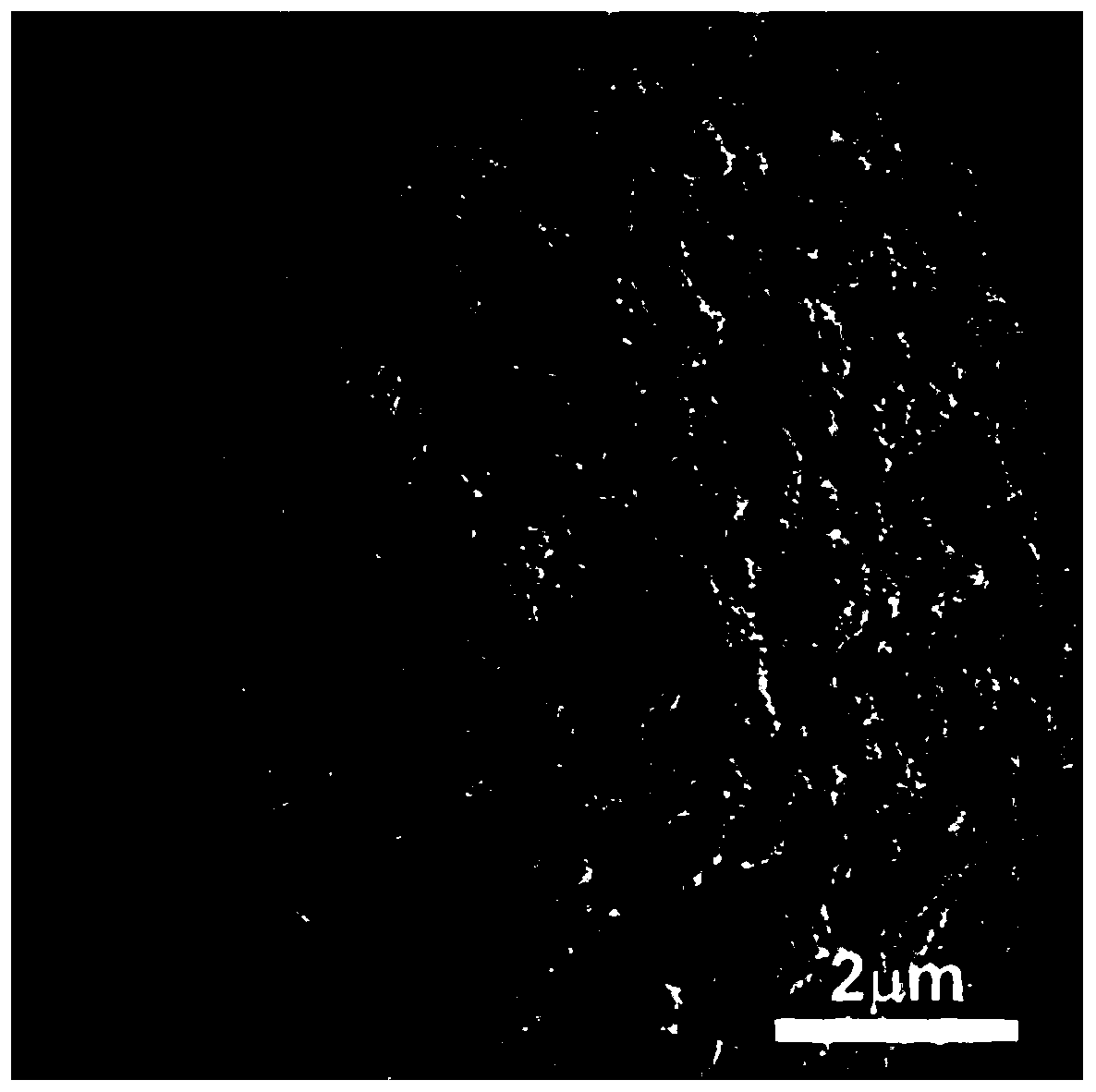

[0044] A method for preparing a metal-organic framework material-coated ternary positive electrode material, comprising the following steps:

[0045] (1) 500mg ternary cathode material LiNi 0.6 co 0.2 mn 0.2 O was dispersed in 50ml of anhydrous ethanol and N,N-dimethylformamide mixed solution, the volume ratio of absolute ethanol and N,N-dimethylformamide was 1:49, and stirred for 1h to obtain a uniform dispersion;

[0046] (2) Under stirring conditions, 35 μl of zirconium n-propoxide (70 wt.% n-propanol solution), 17.5 mg of benzoic acid, and 4.8 mg of terephthalic acid were added to the dispersion, and stirred for 2 hours to obtain a uniformly stirred dispersion. The molar ratio of zirconium atom, benzoic acid and terephthalic acid is 1:5:1.

[0047] (3) Transfer the uniform dispersion in (2) to a reaction kettle with a polytetrafluoroethylene liner for solvothermal reaction. The reaction condition is 120 ° C for 8 hours, and the temperature is naturally cooled to 40 ° C ...

Embodiment 3

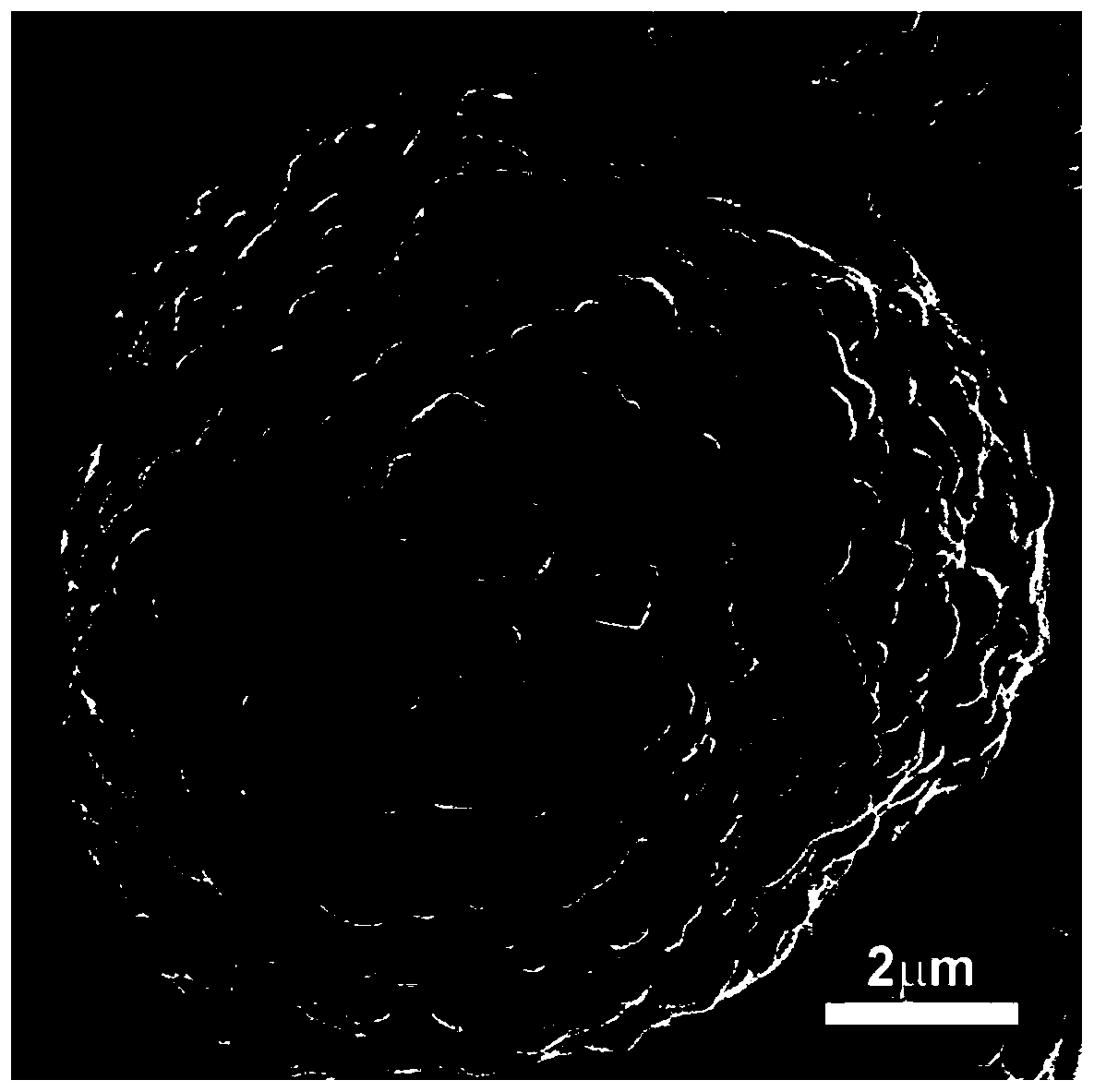

[0052] A method for preparing a metal-organic framework material-coated ternary positive electrode material, comprising the following steps:

[0053] (1) 500mg ternary cathode material LiNi 0.6 co 0.2 mn 0.2 O was dispersed in 50ml of anhydrous ethanol and N,N-dimethylformamide mixed solution, the volume ratio of absolute ethanol and N,N-dimethylformamide was 1:49, and stirred for 1h to obtain a uniform dispersion;

[0054] (2) Under stirring conditions, 35 μl of zirconium n-propoxide (70 wt.% n-propanol solution), 52.5 mg of benzoic acid, and 24 mg of terephthalic acid were added to the dispersion, and stirred for 2 hours to obtain a uniformly stirred dispersion. Wherein the molar ratio of zirconium atom, benzoic acid and terephthalic acid is 1:15:5.

[0055] (3) Transfer the uniform dispersion in (2) to a reaction kettle with a polytetrafluoroethylene liner for solvothermal reaction. The reaction condition is 120 ° C for 8 hours, and the temperature is naturally cooled to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com