Light composite board, production method and application thereof

A technology of composite sheet and production method, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of difficult control of processing process, unfavorable production automation, environmental pollution of raw materials, etc. Light weight and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

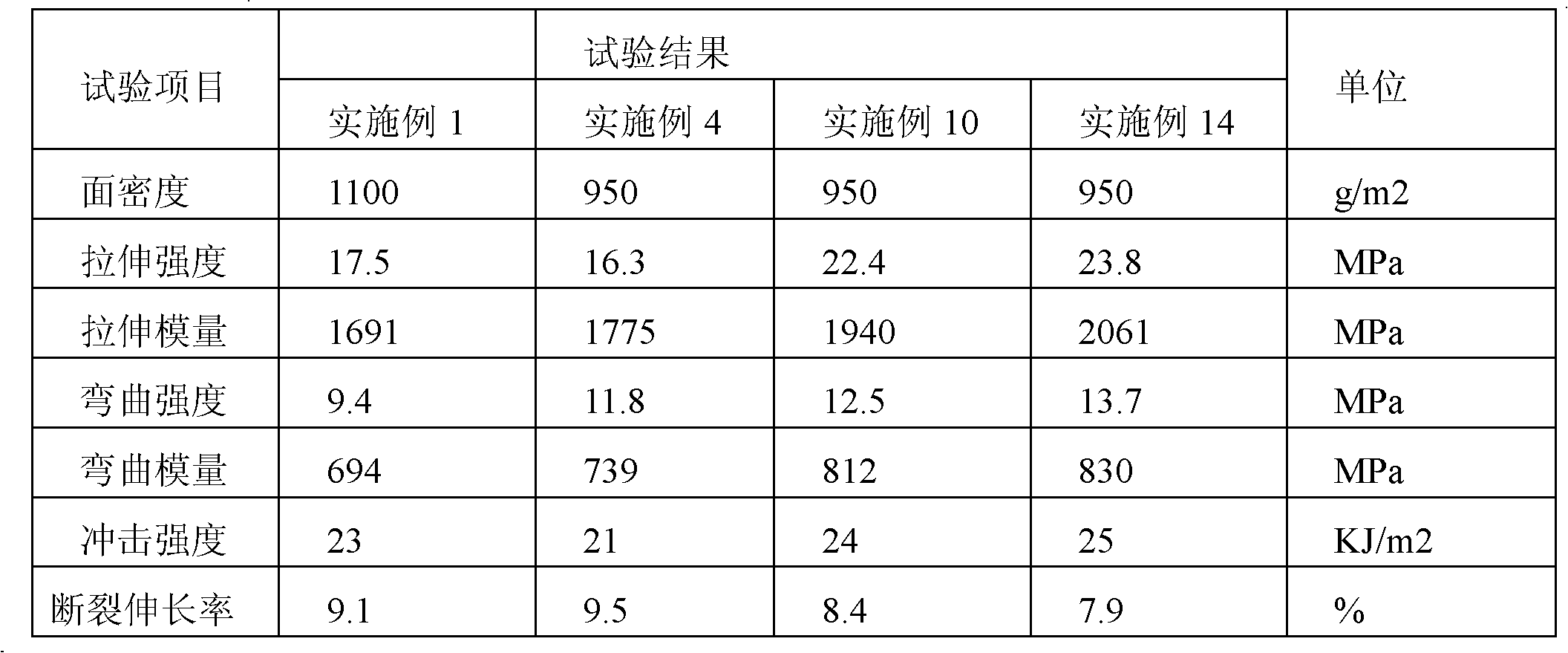

Examples

Embodiment 1

[0043] Take the raw material (kg) according to the following weight: glass fiber 100 (mass percentage composition is 50%), ES fiber 100 (mass percentage composition is 50%);

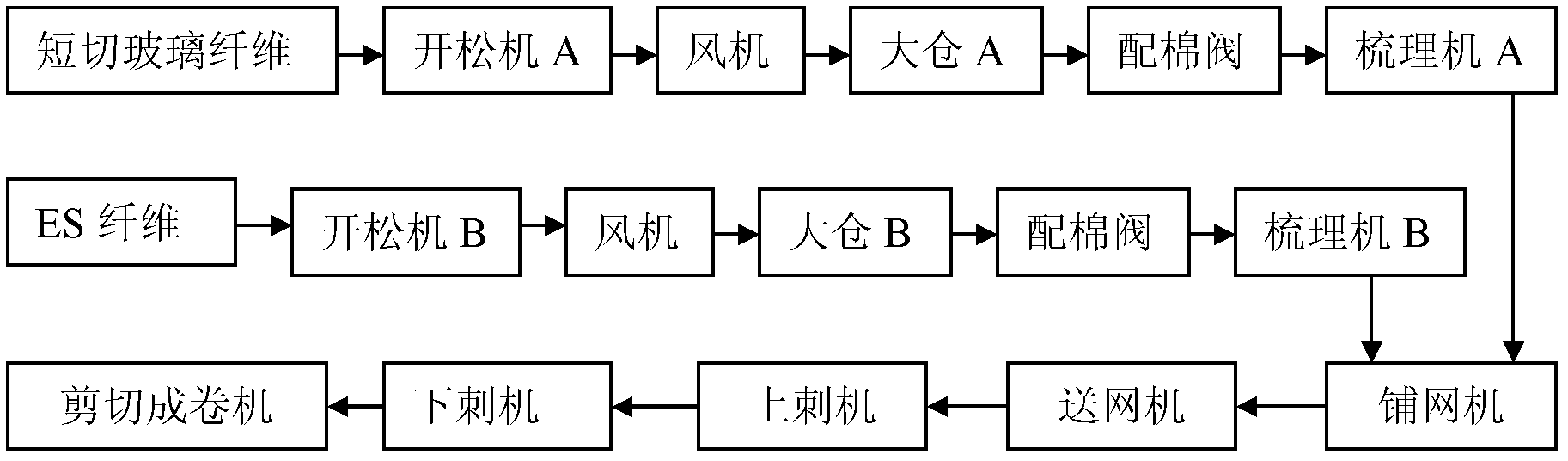

[0044] Methods of producing lightweight composite panels: figure 1 It is a schematic diagram of the process flow of the felting line.

[0045]Unpack and cut 100kg of ES fiber with a length of 76mm and a fineness of 5.5D, and send it to the open conveyor B for opening treatment, and then enter the carding machine B through the fan, large warehouse B, and cotton distribution valve, and then enter the laying machine after carding Lay a net curtain in the machine. 100kg of glass fiber with a length of 80mm and a linear density of 2400tex is unpacked and cut, and sent to the open conveyor A for opening treatment, and then enters the carding machine A through the fan, large warehouse A, and cotton distribution valve, and then enters the net lapper for neutralization after carding The ES fibers in the upper s...

Embodiment 2

[0062] (1) Process flow of felting line

[0063] Take raw material (kg) according to following weight: glass fiber 140 (mass percentage composition is 70%), ES fiber 60 (mass percentage composition is 30%);

[0064] 60kg of ES fiber with a length of 76mm and a fineness of 5.5D and 140kg of glass fiber with a length of 80mm and a linear density of 2400tex are unpacked and cut, and then sent to the open conveyor for opening treatment. The cotton distribution valve enters the carding machine. After carding, the ES fiber and glass fiber enter the net laying machine together to form a net curtain, and then send it to the needle loom through the net feeder, and then go through the upper loom and the lower loom for acupuncture. , enter the shearing and rolling machine into rolls, and the width of the rolls is 1.8-2.2m.

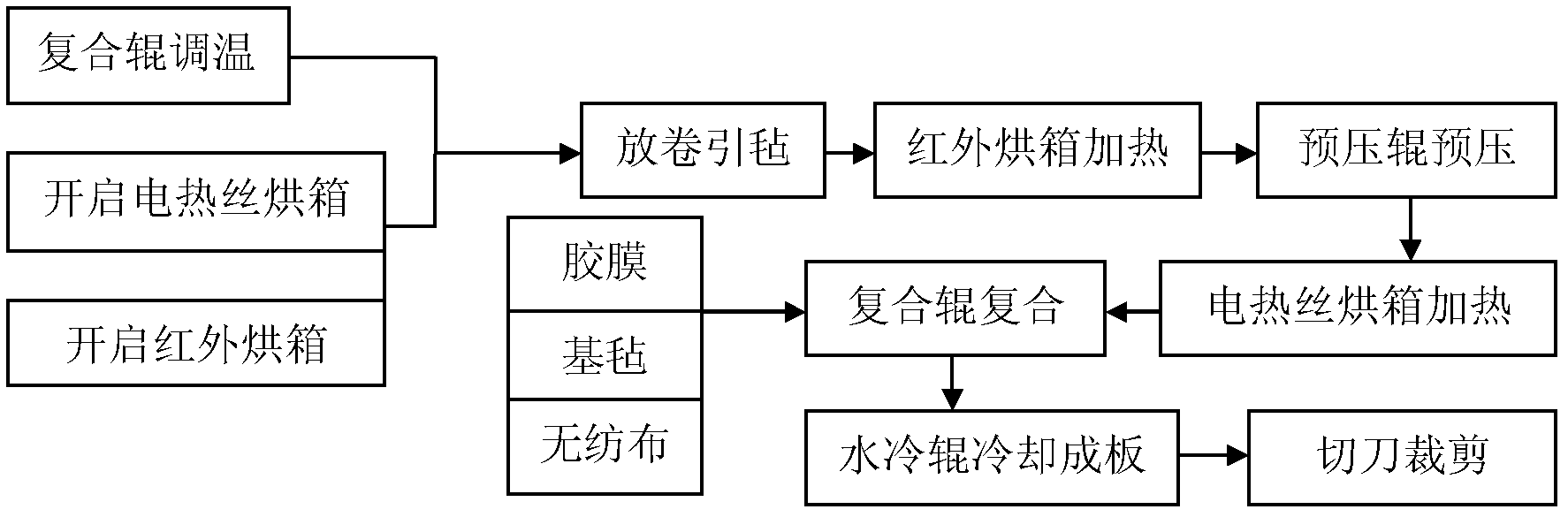

[0065] (2) Process flow of baking line

[0066] First set and adjust the heating temperature of the composite roller, heating wire oven, and infrared oven; among t...

Embodiment 3

[0068] (1) Process flow of felting line

[0069] Take the raw material (kg) according to the following weight: glass fiber 120 (mass percentage composition is 60%), ES fiber 80 (mass percentage composition is 40%);

[0070] 80kg of ES fiber with a length of 76mm and a fineness of 5.5D and 120kg of glass fiber with a length of 80mm and a linear density of 2400tex are unpacked and cut, and then sent to the open conveyor for opening treatment. The cotton distribution valve enters the carding machine. After carding, the ES fiber and glass fiber enter the net laying machine together to form a net curtain, and then send it to the needle loom through the net feeder, and then go through the upper loom and the lower loom for acupuncture. , enter the shearing and rolling machine into rolls, and the width of the rolls is 1.8-2.2m.

[0071] (2) Process flow of baking line

[0072] First set and adjust the heating temperature of the composite roller, heating wire oven, and infrared oven;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com